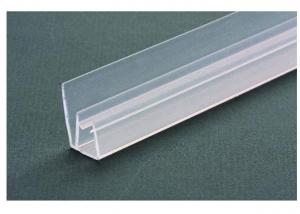

Car Brake Rubber Pad

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces watt

- Supply Capability:

- 10000 Pieces per Week watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Car Brake Rubber Pad

1. It have 12 CNC machines, 3EDM machines, we can make over 100sets rubber mould per month.

2. Compression/transfer/injection(both hot runner and cold runner are available) types.

3. The common mold steel we use are NAK80, P20, 4140, S50C

4. We have 15years experience in making rubber moulds, especially for rubber molds of electronic rubber parts, automotive rubber parts, toy tires, we are a leading rubber mould maker in China.

5. We have our own rubber products workshop, we can test the mold before ship the mold to customer.

6. We are currently making molds for Japan, Italy, UK, USA, Canada, South Asia companies.

7. Experience sales representative discuss with customer about the mold design prior to mold making.

8. Lead-time, prototype mold in 3-7days, production mold in 1-2weeks, complicated rubber molds like cold runner injection rubber molds in 30days.

Description of Car Brake Rubber Pad

Material: comply to RoHS, silicone or rubber (NR, SBR, NBR, EPDM, CSM, CR, HNBR, VITON, AFLAS and more)

Hardness: 8 to 95 shore A, tolerance can be ±5 shore A, for some special products, we can reach ±3 shore A tolerance

Color: for rubber, usually black, for silicone, can be in any color as you want

Machine type: 50 to 400 tons

Molding service: we have our own mold workshop which have 12 sets CNC machines and provide compression/transfer/injection rubber molds

ISO9000 and TS16949 certificated factory

Mold/samples lead-time:

For prototype mold, usually in 7days

For mass production mold, usually in 2 weeks

For some special molds, can be in 30days, especially for some automotive rubber molds

Small orders are welcomed

- Q:What are the mechanisms of the action of the eye plate and the cutting ring of the concrete pump?

- The working principle of the utility model is that the rubber spring is pressed under the action of the pretightening force of the expansion nut, and the cutting ring is tightly jointed with the glasses plate. The cutting ring and the glasses plate belong to a relative motion coupling component, and after the abrasion is generated, the rubber spring can compensate the abrasion amount of the eyeglass plate and the cutting ring by the elasticity of itself, and eliminate the abrasion clearance. When the wear cutting ring reaches a certain degree, the rubber spring compression amount is zero, no pressing force on the cutting ring, screw expansion nut, S tube welding body back tension and compression recovery of rubber spring, then the glasses plate and rubber spring compression, clearance compensation. This method ensures the sealing performance of the glasses plate and the cutting ring well.

- Q:What adhesive do you use for rubber seals on sunroof and glass panels?

- Hello, the car door and window sealing rubber adhesive rubber material, can be directly used YH-818 the adhesive glue, rubber can be torn, to destroy the strength of transparent

- Q:The rubber sleeve of the lower triangular support arm of the car is a little active. What harm does it continue to drive?.

- Rubber is divided into natural rubber and synthetic rubber according to its raw material. According to the form is divided into block rubber, latex, liquid rubber and rubber powder. Latex as a rubber colloidal water dispersion; liquid rubber as an oligomer of rubber, not before the vulcanization is generally viscous liquid; powder rubber is the latex processing into powder, in order to benefit ingredients and processing. Thermoplastic rubber, developed in 1960s, does not require chemical vulcanization and is shaped by thermoplastic processing. Rubber according to the use of divided into general and special type of two categories. It is not easy to insulator, conductive, but if water or different temperature, are likely to become a conductor. Conduction is the conduction of electrons in a substance, molecule, or ion.

- Q:What's the tire composition?

- It also requires high wear resistance and flex resistance, as well as low rolling resistance and heat build-up. Half of the world's rubber consumption is used in tire production, showing the capacity of tires to consume rubber.Automobile tires can be divided into pneumatic tyres and solid tires according to the carcass structure. Most modern cars use pneumatic tyres.

- Q:How does the ceiling fabric come off?

- Polyurethane glue is the molecular chain containing ammonia ester and isocyanate glue, due to the presence of strong polar isocyanate and carbamate radicals, highly reactive, can be cured at room temperature, which has excellent adhesive properties to metals, rubber, glass, ceramics, plastics, wood, fabric, leather a variety of materials such as.

- Q:What material is the rubber hose on the tank truck?

- (1) carbon steel can be divided into three kinds: carbon structural steel, carbon tool steel and free cutting structural steel according to the use, and carbon structural steel is divided into two kinds: construction steel and machine manufacture structural steel;(2) by refining methods can be divided into open hearth steel, converter steel;(3) according to deoxidization methods, they can be divided into boiling steel (F), killed steel (Z), semi killed steel (b) and special killed steel (TZ);(4) according to the carbon content of the steel can be divided into low carbon steel (WC = 0.25%), carbon steel (WC0.25% - 0.6%) and high carbon steel (WC>0.6%);(5) according to the quality of steel, carbon steel can be divided into ordinary carbon steel (phosphorus, sulfur, higher), high quality carbon steel (low phosphorus and sulfur) and high quality steel (lower phosphorus and sulfur) and super quality steel.

- Q:How does the rubber wheel of the material truck effectively clean up quickly?

- The rubber of car model is used commonly butyl rubber and natural rubber two kinds, still have the material that compares almost.

- Q:How does the cleaning agent used in automobile maintenance affect rubber?

- Chemical cleaning agent is very corrosive

- Q:What kind of material is good for heat shrinkable tube of automobile air conditioner?

- There should be four layers of material: 1, the innermost layer is Niron; the 2 layer is chlorinated butyl rubber (CL-HR); 3, the middle layer of polyester fiber reinforced layer; 4, the outermost layer of ethylene propylene rubber (EPDM)

- Q:The role of particle glue on automobiles

- The chassis armor is a high-tech, adhesive, rubberized asphalt coating. It is non-toxic, high covering rate, high adhesion, can be sprayed on the vehicle chassis, wheel hub, oil tank, automobile panels, luggage and other exposed parts, fast drying to form a layer of strong elastic protective layer can prevent the stone and gravel impact, avoid moisture, acid rain, salt erosion of metal for vehicle chassis chassis to prevent rust and corrosion, and ensure traffic safety.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | Domestic Market Rubber and Plastic Products 61.8 Northern Europe Rubber and Plastic Products 2.7 North America Rubber and Plastic Products 10 Oceania Rubber and Plastic Products 0.9 Eastern Asia Rubber and Plastic Products 5.6 Western Europe Rubber and Plastic Products 19 |

| Company Certifications | ISO 9001-2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Car Brake Rubber Pad

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces watt

- Supply Capability:

- 10000 Pieces per Week watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords