NBR Grommets for Kitchen Ware

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

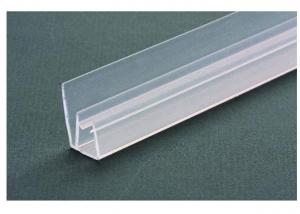

Product Description of NBR Grommets For Kitchen Ware

EPDM/NR/NBR/VITON/FKM grommets.

1. It have 12 CNC machines, 3EDM machines, we can make over 100sets rubber mould per month.

2. Compression/transfer/injection(both hot runner and cold runner are available) types.

3. The common mold steel we use are NAK80, P20, 4140, S50C

4. We have 15years experience in making rubber moulds, especially for rubber molds of electronic rubber parts, automotive rubber parts, toy tires, we are a leading rubber mould maker in China.

5. We have our own rubber products workshop, we can test the mold before ship the mold to customer.

6. We are currently making molds for Japan, Italy, UK, USA, Canada, South Asia companies.

7. Experience sales representative discuss with customer about the mold design prior to mold making.

8. Lead-time, prototype mold in 3-7days, production mold in 1-2weeks, complicated rubber molds like cold runner injection rubber molds in 30days.

Features of NBR Grommets For Kitchen Ware

Material: comply to RoHS, silicone or rubber (NR, SBR, NBR, EPDM, CSM, CR, HNBR, VITON, AFLAS and more)

Hardness: 8 to 95 shore A, tolerance can be ±5 shore A, for some special products, we can reach ±3 shore A tolerance

Color: for rubber, usually black, for silicone, can be in any color as you want

Machine type: 50 to 400 tons

Molding service: we have our own mold workshop which have 12 sets CNC machines and provide compression/transfer/injection rubber molds

ISO9000 and TS16949 certificated factory

Mold/samples lead-time of NBR Grommets For Kitchen Ware

For prototype mold, usually in 7days

For mass production mold, usually in 2 weeks

For some special molds, can be in 30days, especially for some automotive rubber molds

Small orders are welcomed

- Q:How to remove the silver paint on the black rubber strip and black plastic board?

- Physical dataDescription: colorless liquid with banana flavor.Boiling point: 149.25 DEG CFreezing point: -70.8 DEG CRelative Density:0.8756Refractive index: 1.4023Flash point: 25 DEG CSolubility: miscible with organic solvents such as ethanol, ethyl ether, benzene, chloroform and carbon disulfide. Insoluble in water. Dissolve 0.18g/100ml in water at 20 degrees centigrade.

- Q:What are the applications of rubber airbags in the automotive field?

- Sealing system is mainly used to prevent leakage of liquid or other materials, including O ring, rotary shaft oil seal, sealing strip, dust cover, flat gasket and so on. Seals are sometimes made of metal, plastic, or fabric, but more of them are made of rubber. In the early 80s of last century, the United States successfully developed PTFE composite oil seal, successfully solved the problem of engine oil leakage, water leakage, and at the same time greatly improved the technical performance of the car. When the engine and transmission system uses oil series lubricants, the sealing material is usually made of butyl rubber (NBR), acrylic rubber (ACM), silicone rubber (VMQ) or fluorine rubber (FPM).Engine oil requires long life, low viscosity (oil saving), smooth lubrication at high temperature, so engine oil usually contains a variety of additives. Long time soaking HNBR, FPM and ACM at high temperature in an additive containing oil, can maintain high compressive strength. The hydrogenation of chloroprene rubber (HNBR) in which several rubber additives on resistance is the best, at the same time by Ding Xiangjiao (HNBR) heat resistance, oil resistance, aging resistance, is rubber products, currently used in high performance auto parts have been widely. For a long time, the automotive industry has been using NBR and cork rubber to make gaskets for engines, but now uses ACM and VMQ as the main material to satisfy the requirements of heat resistance, sealing capacity and compression durability.The fuel pump diaphragm is a typical fuel pump structure in the carburetor system. The diaphragm has to withstand the thermal impact of the engine and therefore requires not only good durability in the gasoline but also high heat resistance. Because of the need for oxidation resistant gasoline, NBR, HNBR and FPM are available for shock absorbers, insulators, and oil seals in the case of seals. As to which material to choose, the temperature depends on the specific temperature.

- Q:The car roof strip off with what can be glued glue?

- A roof, a waterproof seal can recommend you use glue, jinshida multifunctional soft, pretty good. Sealed waterproof, but also high temperature, the car outside the sun and rain do not affect the gum. The price is reasonable.

- Q:What are the advantages and disadvantages of automobile shock absorber installation?

- Shock absorber - this kind of thing is called a damping rubber ring in general. The main function is that the car bends and reduces the roll of the car. Some students mistakenly believe that adding this stuff will improve the riding comfort of the car, and that's a big mistake!

- Q:What kind of material is good for automobile anti-skid chain?

- Metal friction, of course, can not be said, durable, not to mention. But the comfort is poor, and the car tire injury is relatively large. Personally, it is not suitable for family car use.

- Q:Full coverage of car mats that kind of material better?

- Rubber and leather material surrounded by large mats of cheap, smell great, short service life, it is recommended to select environmental protection XPE and surrounded by a large mat microfiber leather materials, car mats of these two materials are durable, Juegan good, but also by the small temperature difference.

- Q:How to maintain the tires?

- Basically, the car factory should mark the normal tire pressure in the owner's manual or on the inside of the car, such as the inside of the driver's door frame or inside the lid of the filler. Careful number of senior car brands, even the single driving, riding a number of passengers, load, multiple baggage and other conditions should be adjusted to the tire pressure, are clearly marked out. Therefore, it is the most accurate method to check your tire pressure based on the data provided by the original factory. Tire pressure data provided by many car plants are in kilograms / square centimeter (kg/cm2) units. Therefore, you may go to the auto material bank and buy a set of tire pressure gauges marked with this scale, and measure tire pressure periodically.Generally speaking, a 2 litre medium size sedan with a 195/60R15 tire can keep the front tire pressure between 2.2 and 2.4 kg / cm2. Often the number of passengers carrying or carrying a large number of car owners, tire pressure value must be 0.2 or more than the normal value of 0.1 to about. In addition, digital tire pressure medium can be, do not hit too high, if it is a long drive in the hot summer climate, or to the highway, it should also be appropriate to help improve the tire pressure, tire heat.

- Q:How do I fix the car wiper strips?

- Windshield wiperEvery time the car wash, in addition to cleaning glass windows, it is best to use glass cleaning liquid wiper wiper, so that the life of the wiper bar will be more.

- Q:Auto window black rubber strip crack, what stick best?

- You are talking about the window seal. If you break it, it should be rubber aging. You'd better go to the auto repair station to replace the new one;If it is accidentally cut hole, and reluctant to change, then use 502 sticky

- Q:What is the swelling glue used in automobiles?

- Typical use:The utility model is suitable for the shock absorption and bonding between the automobile sheet metal and the stiffener, the framework and the support frame. Shock absorption of door, body, outer panel, outer panel and frame.Advantage:Easy construction, excellent adhesion on oil surface.High expansion rate, good adhesion, elasticity, sound absorption, shock absorption and noise reduction results from tightness.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | Domestic Market Rubber and Plastic Products 61.8 Northern Europe Rubber and Plastic Products 2.7 North America Rubber and Plastic Products 10 Oceania Rubber and Plastic Products 0.9 Eastern Asia Rubber and Plastic Products 5.6 Western Europe Rubber and Plastic Products 19 |

| Company Certifications | ISO 9001-2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

NBR Grommets for Kitchen Ware

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords