Cantilever winding machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cantilever winding machine made in China

Description of Cantilever winding machine made in China

The cantilever type winding and wrapping machine is mainly applied to the overall wrapping of lighter or heavier goods in the food, beverage, chemical, papermaking, building materials and other industries. Its packaging cost is low and its efficiency is high. The installation method of the machine is flexible and can be installed on the wall, or it can be fixed by the bracket. At the same time, according to your actual requirements, you can use stand-alone or online equipment to achieve automatic packaging and automatic delivery of goods.

Packaging machinery refers to machinery that can complete all or part of the product and product packaging process. The packaging process includes major processes such as filling, wrapping, and sealing, as well as related processes such as cleaning, stacking, and disassembling.

In addition, packaging also includes processes such as metering or stamping on packages. The use of mechanical packaging products can increase productivity, reduce labor intensity, adapt to the needs of large-scale production, and meet the requirements of cleanliness and hygiene.

Main Features of Cantilever winding machine made in China

Membrane system: pre-stretched film frame, pre-stretch up to 250%, automatic film feeding, adjustable film feeding speed

Lifting column: chain structure, adjustable frequency of lifting speed

Control system: PLC programmable control, push-button operation panel, simple and clear

Operation function: automatic operation, automatic machine setting function

Cantilever performance: high-sensitivity emergency braking system, automatic cantilever reset

Automatic film breaking device: automatic clamping, cutting off the stretch film and achieving unattended operation

Conveyor system: conveyor line height: 400mm, conveyor line speed: 15m/min, conveyor line load: 1500kg

Safety protection: eye-catching flash safety warning and protective net (optional), photoelectric protection of incoming and outgoing goods (conveyor line)

Equipment composition: cantilever winding packaging machine + square gantry bracket +4m power transmission line + automatic on-off film

Specifications of Cantilever winding machine made in China

| Wrapping specifications | L500-1300mm*W500-1200mm*H300mm-1800mm |

| Packaging height | Customized according to customer requirements |

| Packaging efficiency | 20-30 pieces/hour 0-14 turns/minute |

| Membrane system | Pre-stretched film holder |

| Lifting column | Double chain structure, |

| Power/voltage | 1.9KW/AC220V |

| Packaging Materials | LLDPE stretch film, thickness 17-35um, width 500mm paper core: 3 inches |

| Dimensions | L3760*W2000*H3220mm with four pillars |

Applications of Cantilever winding machine made in China

Applicable to chemical fiber, tobacco, pharmaceuticals, publishing, refrigeration, home appliances, ceramics, beverages, hardware, chemicals, cans and other industries.

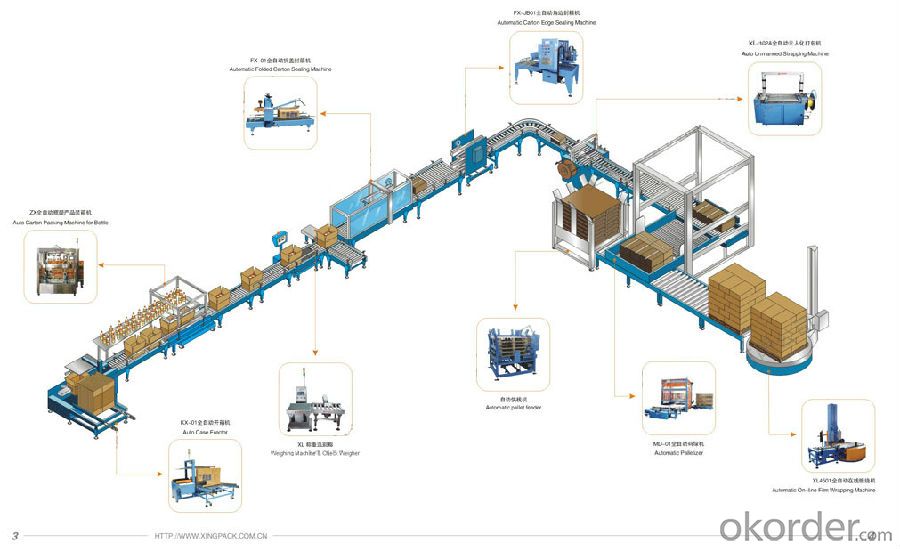

Images of Cantilever winding machine made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q:What are the main plastic forming processes?

- 5. low pressure molding. A touch or laminating method using a molding pressure equal to or less than 1.4 mpa.Low pressure molding is used to make reinforced plastic products. Reinforced materials such as glass fiber, textiles, asbestos, paper, carbon fibers, etc.. Most resins used are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins.Low pressure molding includes bag pressing and spraying.(1) bag pressing forming. A method of forming a workpiece by applying fluid pressure to an elastomeric plastic between a rigid mold and an elastic bag by means of an elastic bag (or other flexible diaphragms). According to the different methods caused by fluid pressure, can generally be divided into pressure bag molding, vacuum bag molding and autoclave molding etc..(2) spray forming. When molding reinforced plastic products, a method of spraying a short cut of fibers and resins simultaneously onto a mold and solidifying them into an article by means of an airbrush is described.

- Q:Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q:Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- If these are good, and then talk about the price, always a penny goods, this side, quick packaging machine is not bad,

- Q:What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q:What's the fastest packing machine?

- Because the packaging machine type is more complicated, according to the state, liquid, bulk, powder, granular packing machine; according to the function of packaging, packaging, packaging machine in outsourcing; according to the packaging industry, food, daily chemical industry, metal parts, textiles and other packaging machine; according to the packing station. A single station and multi station packing machine; divided by automation, automatic packing machine, also has semi-automatic and so on. According to the form of sealing, it can be divided into back sealing type, three sides sealing, four sides sealing, triangle and so on. According to the product form, it can be divided into pillow type packaging machine, vertical packaging machine, vacuum packaging machine, sealing machine and so on

- Q:Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q:Is there anyone who knows what groups of users of packaging machinery are in general?

- If automated packaging, it depends on the factory situation, should not be from the user groups to start. If a small class of cosmetics do, then he will not say to buy a more than ten thousand or hundreds of thousands of automated equipment to pack ah. Automatic packing machine is certainly need a certain amount, a certain basis will be needed, or buy a mechanical automation a month the amount of packaging takes less than one hour, then buy this station automation machinery to do what? So, according to the automatic device, we can not start from the user groups, should be considered from the size of the factory.

- Q:The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q:Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q:Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cantilever winding machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords