Fiberglass Mat Tissue C-Glass Woven Roving for Pultrusion

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

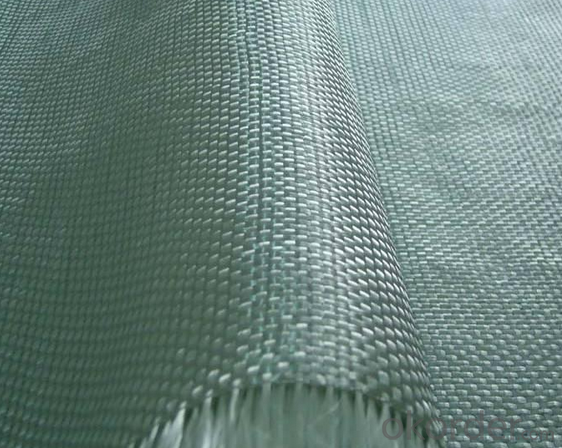

Structure of Woven Roving

1)Low Fuzz

2)Fast Wet-out&Impregnation

3)Easy Lay-up&Air Release

4)Excellent Mechanical Strength

5)Good Wet Strength Retension

6)Good Laminate Transparency

Main Features of Woven Roving

1.CWR400

2.360-380g/m2

3.77.5px or 2250px width

4.plastic woven bag

Application of Woven Roving

Unit | Product No. | Weight(gsm) | Technique | Moisture content | combustible matter content(%) |

M | EWR260 | 264±13 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR270 | 261±13.5 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR360 | 354±18 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR500 | 504±25 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR580 | 576±29 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR600 | 622±30 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR800 | 850±40 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR200 | 200±15 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR400 | 385±30 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR600 | 600±45 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR800 | 810±40 | Plain | ≤0.15 | 0.40-0.80 |

Images:

FAQ of Woven Roving

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Does fiberglass mat tissue require any special curing conditions?

- Fiberglass mat tissue does not typically require any special curing conditions. It can be cured at room temperature without the need for high temperatures or specific curing environments. The curing process of fiberglass mat tissue involves the application of resin, which hardens and bonds with the fibers over time. This curing can occur naturally at room temperature or can be accelerated with the use of heat or catalysts. However, it is important to follow the manufacturer's instructions and recommendations for the specific type of fiberglass mat tissue being used, as some variations may have specific curing requirements.

- Q: Is fiberglass mat tissue suitable for aerospace interiors?

- Fiberglass mat tissue is indeed a suitable material for aerospace interiors. This material is both lightweight and extremely versatile, providing exceptional strength and durability. Its widespread use in aerospace applications is due to its ability to meet rigorous fire safety standards, including low smoke and toxicity emissions. Furthermore, fiberglass mat tissue exhibits resistance to moisture, chemicals, and temperature fluctuations, making it an ideal option for the challenging conditions found within an aircraft cabin. Its exceptional sound insulation properties further contribute to its suitability for aerospace interiors, guaranteeing a pleasant and noise-free environment for passengers. All in all, fiberglass mat tissue offers a dependable and effective solution for aerospace interior applications.

- Q: Is fiberglass mat tissue resistant to moisture?

- Fiberglass mat tissue, indeed, exhibits resistance to moisture. By tightly weaving strands of glass fibers and subsequently bonding them with a resin, this tissue fabricates a barrier that effectively thwarts the infiltration of moisture. Consequently, the moisture-resistant properties of fiberglass mat tissue render it exceptionally suitable for deployment in scenarios where water exposure or high humidity is anticipated. Moreover, this tissue's resistance to moisture aids in averting the proliferation of mold or mildew, thereby establishing it as an appropriate selection for environments prone to dampness.

- Q: Is fiberglass mat tissue suitable for insulation in chemical processing plants?

- Yes, fiberglass mat tissue is suitable for insulation in chemical processing plants. Fiberglass mat tissue is made from fine glass fibers bonded together with a binder, which gives it excellent thermal insulation properties. It can withstand high temperatures and is resistant to many chemicals, making it ideal for use in chemical processing plants where there may be exposure to corrosive substances or high heat. Additionally, fiberglass mat tissue is lightweight and easy to install, making it a cost-effective choice for insulation in these types of industrial environments.

- Q: How does fiberglass mat tissue perform in terms of heat insulation?

- Fiberglass mat tissue exhibits a relatively satisfactory performance when it comes to heat insulation. Its composition, consisting of delicate glass fibers and a bonding agent, grants it commendable thermal resistance properties. These fibers effectively capture pockets of air, which function as thermal barriers by diminishing heat transfer. Consequently, fiberglass mat tissue emerges as an appropriate insulation material for a diverse range of applications, including the construction industry, where it is employed to insulate walls, roofs, and attics. Furthermore, fiberglass mat tissue finds extensive use in the automotive and aerospace sectors to insulate engine compartments and curtail heat transfer through vehicle panels, respectively. Nevertheless, it is worth noting that although fiberglass mat tissue offers exceptional thermal insulation, it may not be as efficient as alternative insulation materials like foam or mineral wool, which possess higher thermal resistance values. Ultimately, the suitability of fiberglass mat tissue as an insulation material hinges upon the specific requirements of the project at hand.

- Q: Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not suitable for making furniture. It is primarily used in composite materials and construction applications, not for furniture manufacturing.

- Q: How does fiberglass mat tissue compare to polystyrene insulation?

- Fiberglass mat tissue and polystyrene insulation serve different purposes as insulation materials, each with their own unique characteristics and advantages. Fiberglass mat tissue is composed of woven strands of glass fibers that form a mat. It is commonly used for heat and sound insulation. This material is known for its exceptional thermal insulation properties, effectively resisting heat transfer in both hot and cold environments. Additionally, it is resistant to moisture and does not facilitate the growth of mold or mildew. On the other hand, polystyrene insulation is a foam material made from expanded polystyrene beads. It is widely used in construction due to its ability to provide efficient thermal insulation and its adaptability to different spaces through shaping or cutting. Polystyrene insulation is recognized for its high compressive strength, making it ideal for applications requiring support. It is also lightweight, resistant to moisture, and exhibits excellent durability. When comparing fiberglass mat tissue to polystyrene insulation, several notable differences should be considered. Fiberglass mat tissue is generally more flexible and easier to install on irregular or curved surfaces. Moreover, it offers superior fire resistance, as it does not burn or emit toxic gases when exposed to flames. However, fiberglass mat tissue tends to be more expensive than polystyrene insulation and may necessitate additional protective measures during installation, such as gloves and masks, due to potential skin and respiratory irritation. Conversely, polystyrene insulation is more cost-effective and simpler to handle and install compared to fiberglass mat tissue. It also exhibits enhanced resistance to moisture, making it suitable for applications in humid environments or areas prone to water exposure. Nevertheless, polystyrene insulation is more flammable than fiberglass mat tissue and releases toxic gases when burned. In conclusion, the choice between fiberglass mat tissue and polystyrene insulation depends on the specific requirements of the insulation project. Fiberglass mat tissue excels in thermal insulation, fire resistance, and resistance to moisture and mold. On the other hand, polystyrene insulation offers efficient thermal insulation, ease of installation, and high compressive strength. Ultimately, factors such as cost, installation requirements, fire resistance, and moisture resistance should be carefully considered when selecting between fiberglass mat tissue and polystyrene insulation.

- Q: Is fiberglass mat tissue fire resistant?

- Certainly, fiberglass mat tissue exhibits fire resistance. This quality originates from its composition of glass fibers and resin, which grants it exceptional fire-resistant attributes. Possessing a considerable melting point, it resists ignition and combustion with ease. Moreover, fiberglass mat tissue frequently undergoes treatment with fire-resistant coatings or additives, bolstering its fire-resistant capabilities to an even greater extent. Consequently, fiberglass mat tissue finds extensive use in diverse applications necessitating fire resistance, including insulation materials, protective clothing, and fireproof barriers.

- Q: Can fiberglass mat tissue be used for making lightweight partitions?

- Yes, fiberglass mat tissue can be used for making lightweight partitions. Its lightweight and flexible nature makes it an ideal material for constructing partitions that are easy to install and move, while providing adequate strength and insulation.

- Q: Is fiberglass mat tissue suitable for insulation in HVAC ducts?

- Yes, fiberglass mat tissue is suitable for insulation in HVAC ducts. Fiberglass is a commonly used material for insulation due to its excellent thermal and acoustic properties. It is capable of withstanding high temperatures and is resistant to moisture, making it ideal for ductwork applications. Fiberglass mat tissue provides effective insulation by reducing heat transfer and preventing condensation buildup within the ducts. Additionally, it is lightweight, easy to install, and has a long lifespan, making it a cost-effective choice for HVAC insulation. Overall, fiberglass mat tissue is a suitable and reliable option for insulation in HVAC ducts.

Send your message to us

Fiberglass Mat Tissue C-Glass Woven Roving for Pultrusion

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords