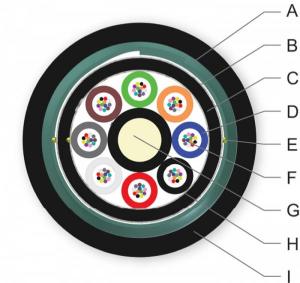

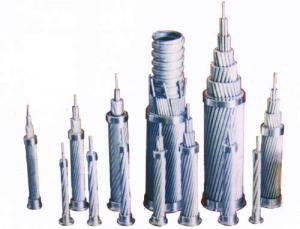

Black Silane XLPE Compound for 10KV and Below Aerial Hanging Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000kgs kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Grade 4215 is specially used for 10KV below aerial hanging power cable, it is composed by 90% silane crosslinkable low density polyethylene (compound A) and 10% black catalyst (compound B). The product has outstanding performance in anti-ageing property, wild processing temperature,easy processing characteristics and excellent product quality.

Standard

After crosslinked in the tepid water, the cable made from the product grade 4215 can comply with the standard of IEC60502-2004, GB/T14049-2008.

Main Properties & Typical Values

Test Items | Unit | Test Method | Standard | Typical value |

Tensile strength | MPa | GB/T1040.3 | ≥13.5 | 19.0 |

Elongation at break | % | GB/T1040.3 | ≥300 | 460 |

Heat ageing properties (Test temperature 135℃, 168hr) Maximum tensile strength change Maximum elongation at break change |

% % | GB/T8815 |

±20 ±20 |

7.2 6.0 |

Heat elongation (200±3)℃x15minx0.2MPa) Maximum elongation change under load Maximum permanent elongation change after cooled |

% % | GB/T2951 |

≤80 ≤5 |

60 2 |

Impact brittle temp. (-76℃) Impact brittle | Failure no. | GB/T5470 | ≤15/30 | pass* |

Dielectric Strength | MV/m | GB/T1408.1 | ≥30 | 37* |

Dielectric loss factor 50Hz, 20℃ | -- | GB/T1409 | ≤1×10-4 | 1×10-4* |

Dielectric constant 50Hz, 20℃ | -- | GB/T1409 | ≤2.35 | 2.2* |

Volume resistance (20℃) | Ω·m | GB/T1410 | ≥1.0×1014 | 1×1014* |

Pressure crack test F50 | hr | GB/T2951 | 1000 | pass* |

Artificial atmosphere ageing properties: Ageing After 42days, Maximum tensile strength change Maximum elongation at break change Ageing after 42days vs. after 21days Maximum tensile strength change Maximum elongation at break change |

% %

% % | GB/T14049 |

±30 ±30

±15 ±15 |

-15 -20

-10 -11 |

Typical values 1-4, 11 were tested on the sample strip by squeezing film extrusion after mixing compound of A & B (at percentage of 90:10) and be boiled in hot water at 90℃ for 4 hours.

*Especially, these typical values were tested by press moulding sample (A and B mixed atpercentage of 90:10), under the condition of 180±2 ℃, 15min, and pressure over 15Mpa, then boiled in 90℃ water for four hours.

Recommended Processing Technique

1. Extrusion Equipment

Most extruders for PVC and PE suit for 4215

The recommended equipment and processing technique is as following.

Ratio of length and diameter 18—25:1

Diameter 45—120mm

Ratio of compressing 1.5—3.5

Ratio of elongation 1:1.0—1:1.5

Filtering mesh 40/60/40

2. Extruder processing temperature and other related settings

Temperature Setting: Specific processing temperature should be based on different equipment and pressing conditions, reference settings are as following:

Feeding Section(℃) | Compression Section(℃) | Measurement Section (℃) | Die head and Mould (℃) |

150~165 | 165~177 | 175~190 | 190~200 |

Die head setting: Squeezing extrusion style and tubing extrusion style

Cooling water temperature: Should not be less than 25℃, when using tubing style extrusion method, gradual cooling water tank is recommended for better control the heat shrinkage.

3. Crosslink

After extrusion and cooling, the cable can be crosslinked by immersed in hot water (90℃) or exposed in low pressure vapour. The time required for crosslink is based on the thickness of the insulation and the coil size, the thicker the insulation and the greater the coil size, the longer the crosslink time required. The crosslink time can be calculated according to the equation of 4hr/mm for 90℃.

- Q:Wire and cable CCC product consistency is what

- Wire of course, is to use a good slightly, the first life, ah, can not buy cheap because of cheap, like China's top ten brands to buy the brand on the purchase of these brands I feel very good ah, Po Sheng , Luneng Taishan, Far East, Shenghua cable, on the up, prosperous photoelectric, Nexans Nexans these brands of wire is still very good. The landlord you can go to the above to learn more detailed information ah, the top ten wire brand is very detailed, the landlord can understand very clearly, the above brand is very good, my father last time to go above to see, and then buy

- Q:I would like to ask my new workshop power consumption of about 500KW, injection molding machine, 60KW . 40KW . 20KW . the other 20KW, how much should the wire? Respectively how to use lines and switches more

- No way to save money! Moreover, the signal to you there, almost all attenuation finished.

- Q:Do not know why not mislead. The The The The The Fire resistance is IECGBBS6387. GB is the general principle of flame retardant and fire resistant wire and cable, quoted the above criteria...........................

- About 140 PVC threading tube, which depends on how many lines you row. PPR cold / hot water pipe 42 meters, PPR cold / hot water pipe with 4 m / root and 6 m / root of the points, short will make the joints more recommended to use long, generally longer expensive. Decoration in meters to count, to facilitate the settlement of labor, 42 meters is the amount of my home My house 115 square meters, indoor area of 98 square meters. I hope useful to you. According to the 2011 price, the general brand of wires and pipes, their own materials to buy, without artificial about 4000-5000 yuan. I decorated last year, the package to the decorating company hydropower workers with me to calculate the 9800 yuan it, of course, each region has a price difference.

- Q:IPadmini. The latest version 7.1.1 up in the morning to see the non-stop display this cable is not certified does not support this feature. The The Charger original. Not on the computer charge. The Ask God to answer more

- The problem lies in the charger between the machine, IPAD charging is to a charging protocol to complete, when the IPAD did not receive the agreement signal will be prompted: do not support this accessory, Apple's products have charging protocol, charging Is through the data line in the two lines and IPAD transmission charging protocol signal when ipad received the charging protocol signal after the machine internal charging circuit began to open the internal charging circuit to charge, the problem is to accept the charge signal is not so prompted not to Support, change the line to try

- Q:What is the difference between the WDZ wire and cable, the ZR wire cable and the NH wire and cable, and what kind of wire and cable should be used?

- Do not know why not mislead. The The The The The Fire resistance is IECGBBS6387. GB is the general principle of flame retardant and fire resistant wire and cable, quoted the above criteria.............................................

- Q:What is the warranty period for wire and cable?

- Hello according to your request can be used two sets of ordinary 16 cascade, to a control terminal control 32 hosts. Is the cheapest solution. According to my understanding of the domestic Haikang series of products cost-effective, you can understand the next.

- Q:Remove the computer and wash it off. What the motherboard did not move it, that is, the dust of those dust sasses, as well as the other wire of the skin what Sassafras wash, but the computer re-connected to the Internet when the old mistakes . and the lower right corner of the red Fork appears, disappeared after the emergence. The The Said the network cable is not plugged in, but the MODERN that POWER, LINK, LINE, 3 lights are normal display. The The This is how the matter, and just also appeared keyboard and mouse just start the machine can also be used normally, but in a moment to fall, and then plug their plug re-plug the mouse lights can be displayed, but the lights on the keyboard simply do not Bright, restart the computer but good, what is going on? bother. The The I hope the master quickly to help me, and this machine is relatively old ah No problem added: on a machine, just tried to re-create a connection in the network neighborhood, useless more

- Galvanized itself on the anti-corrosion, no need to do anti-corrosion treatment.

- Q:Rt, the charger did not change, has been no problem before, today just plugged into the charger, the results appear as if the problem, before the out of this problem, and now only ipad power off after the power can not be charged, and ipad start , Then immediately prompted the title, can not charge more

- Budget 1W5 requires the whole machine to include the display of the monitor not too big too much Not used to more

- Q:What are the T and T, s of the wire and cable test type?

- The expression is not very clear, it should be said to wear a tube, if a single wear on the line 100. Outside diameter 60mm.

- Q:Apple 6 Charging Why always show this cable has not yet been certified

- And I answered the other person's question is very similar: . the line of the banding distance of not more than 1.2 meters, the two ends of the wire box outlet tube 15CM should be ligation; . casing embedded, then through the basement wall, the surface must be installed rigid Waterproof casing, that is, steel pipe + water ring; through the fire pool, living pool: flexible waterproof casing; (wing ring specific practices can be collected online related Atlas); through the floor, according to whether the design requirements , Under normal circumstances PVC casing on it. Note: . rigid waterproof casing, flexible waterproof casing is a one-time reserved in place, through the floor of the casing of the flower lamb to suppress the barge of Xi Jie Xi Xi shou, is the first stay hole, when the installation of riser Casing, because the floor casing has every layer, the location of the reservation will always be biased, in order to ensure vertical vertical pipe, and finally unified hanging line repair hole and then install the riser and casing. . now most of the bathroom are dirty, waste and diversion, and more of the riser, and so on, the air conditioning casing of all the shear wall should be embedded, to avoid the subsequent damage to the structure of drilling (no stay can only drill) Note that the location of the hole and the installation of the riser will affect the opening of the toilet window. . the casing is the casing, riser is the riser, casing than the riser model 1 to 2 level. . plate at the end of flat, board 2 to 5CM higher to see if you need to do leveling layer.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Black Silane XLPE Compound for 10KV and Below Aerial Hanging Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000kgs kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products