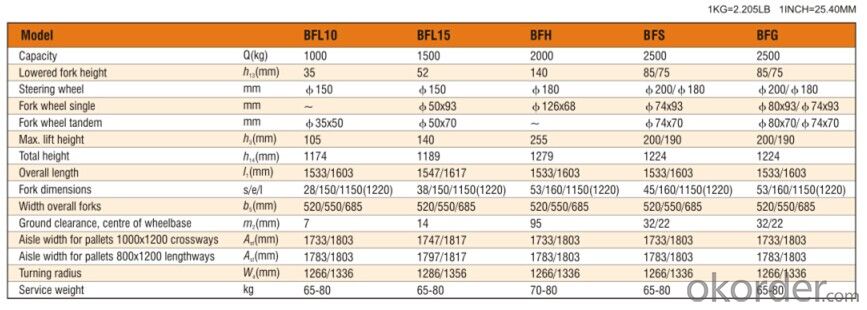

BFS MULTI-FUNCTION HAND PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What is the relevant content of the flow of materials, storage and usage

- Unitized packaging and standardization is the foundation of the enterprise logistics work, for the protection of the components, the follow-up of logistics planning and the determination of through put play a key role. Adopt the reasonable unitized equipment, can reduce the invalid labor (such as inversion, not fall to the ground) in the process of machining, improve labor efficiency, simplify the site management, reduce the security hidden danger. The idea of packaging unitization and standardization is controlled mainly from macro and micro level. On the macro level, we need to set the size chain for all materials from the perspective of the supply chain. From the tray to the turntable, the special frame should be coupled with this dimension chain. On the micro level. In order to meet the basic requirements of packaging design, such as the principle of protecting spare parts and saving space, choose the proper packaging materials, internal separation materials and so on. At the same time, the loading number of the packaging unit should be fixed so as to reduce the statistical workload of the on-site staff. Some factories have higher management requirements for packaging and line workstations, which require the packaging to be incorporated into the day-to-day management of the process. For packaging, cleaning, cleaning (cleaning oil, labeling, etc.), repair, storage, etc.

- Q:The development of material handling

- The material handling equipment manufacturing industry provides various kinds of modern transportation equipment for the national economy, major construction projects and national defense security. Basic formed a comprehensive product range, good technical system and large enterprise groups, become an independent industry, machinery industry in the service of national economy in all walks of life, including for the second and the third industry provides a huge number, a great variety of products, can independently or with foreign cooperation for national key project to provide large lifting transportation machinery and complete sets of equipment system, and have a certain amount of exports. In 2011, there were 1,580 enterprises in the manufacturing industry of material handling equipment in China (RMB 20 million), and more than 400 000 employees. The industry realized sales revenue of 4723.47 billion yuan, with an industrial output value of 4712.23 billion yuan, with a total profit of 34.50 billion yuan, with an average annual compound growth rate of over 20%. With the expanding of the scale of production, improve degree of automation, material handling equipment manufacturing industry is more and more widely used in the process of modern production, function more and more big.

- Q:What are the potential defects of the automated material handling system?

- Stacker crane Automatic stacker crane is a machine, electrical integration of high-tech products, products mainly to the (box, bag, barrel), through a continuous mechanical action, according to certain order stack to the corresponding empty tray, to facilitate the batch product handling and transportation, so as to improve the efficiency of the production. According to the height of the entry, different stacker machine is divided into high and low stack.

- Q:What is the rational and scientific classification of logistics facilities and equipment

- Generally be divided into logistics facilities and equipment, logistics equipment, logistics, warehouse facilities and equipment, logistics transportation facilities and container handling equipment, logistics equipment, logistics, circulation unitized equipment, port logistics facilities and equipment processing equipment, automatic sorting equipment, information platform and equipment. Logistics infrastructure refers to the service function of a supply chain and some of the supply chain process, meet the need of logistics organization and management, which has the function of comprehensive or a single place or organization collectively, mainly including roads, railways, ports, airports, distribution center and network communication, etc. Logistics infrastructure includes warehousing, delivery facilities, and computing and information communication equipment.

- Q:Talk about how to cut the cost of moving materials.

- I think the main thing is to choose a range of suitable devices. If the moving objects and routes are relatively fixed, the use of the manipulator can be more efficient. The cost is naturally reduced.

- Q:There are three things to do when the material is stacked up and down

- Fire prevention, waterproof, and do not exceed the limit.I hope my answer will help you.

- Q:The principle of material handling

- Unit rule principle: increase the amount, size, or weight of the unit load. Mechanization principle: mechanization of carrying work. Automation principle: provides automation of production, handling and storage. Equipment selection principle: when choosing a moving equipment, the various elements of the moving material should be considered, including the moving and method used. Principle of standardization: to standardize the method of handling and the type and scale of the carrying equipment.

- Q:What is the carrying equipment of the container cargo

- Container (container), crane, forklift truck Kunshan city peng a lift lifting transportation and handling professional clean room equipment installation, precision air handling import and export container, unpacking, assembling positioning, whole factory move, special lifting engineering contracting, precision machine packed in wooden cases

- Q:The material needs to be transported, it is easy to produce dust.

- Hello! There are many successful users in the coal-mining plant, such as shenhua, jun, Venus, and extended oil. Before choosing the right device, you need to specify two things: Objective conditions: the operating conditions of the factory, the layout of the workshop space, the material situation and the capability requirements, which conveyance equipment is currently used.

- Q:What is the material handling and handling equipment?

- Logistics system software logistics system performs software | analysis tool software | system tool software 15. Ship shipping equipment barge/mother ship... Empty shipping equipment, etc

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BFS MULTI-FUNCTION HAND PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords