Bearings four row cylindrical roller FC2028104

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Four row cylindrical roller bearings

Four row cylindrical roller bearing is usually use in rolling mill’s work roll or back-up roll. It mainly take much radial load, which is extensively used on the work roll of wire rod mill, section mill and bloomer mill , as well as the back-up roll of dressing machine, cold rolling mill and hot rolling mill.There are three kinds of structures: FC, FCD, FCDP. There are three grades for tolerance : 0 , 6 , 5.

FC: double outer ring, single inner ring, inner ring without rid;

FCD: double outer ring, double inner ring, inner ring without rid;

FCDP:double outer ring, double inner ring, inner ring without rid

★ Product Features:

The rollers of the cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from

another ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing

can be easily mounted and dismounted. Its advantages are obvious especially when there is

interference fits between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer

rings flanges can bear small steady axial load or great intermittent axial load. It has a high

requirement on the processing of the fitting parts such as axis and housing bore, etc.

★Product Application:

Cylindrical roller bearings are mainly used for:

- Iron and steel metallurgical industry

- medium and large motor

- generator

- combustion engines

- gas tuibine

- machine tool spindle

- speed reducer

- loading and unloading machinery and all kinds of industrial machinery

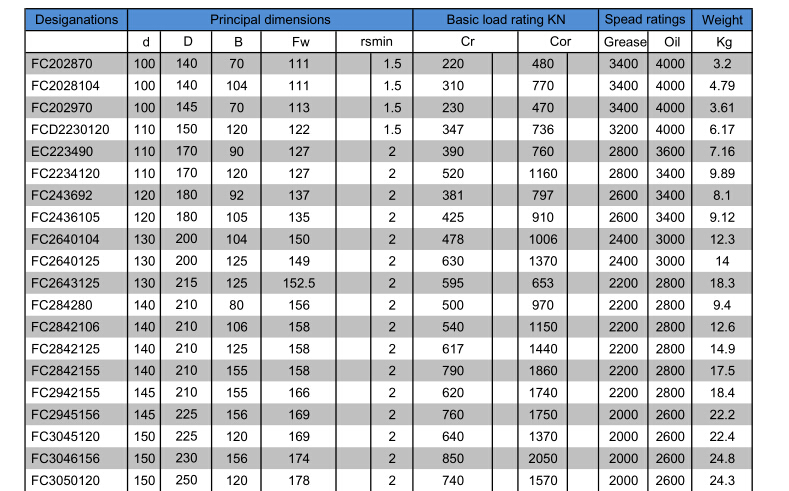

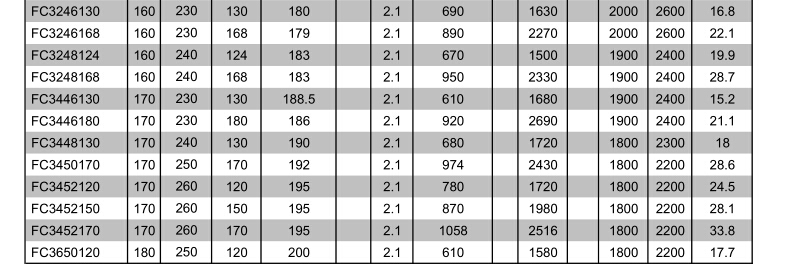

Four Cylindrical Roller Bearings Catalugue

- Q:In the car there is a cylindrical roller, the size of the diameter of 25mm, the outer diameter of 32mm, width of 9.5mm, who knows what the standard size, have direct purchase Mody, thank you!

- This could be a car only bearing! NSK sample short column can not find the corresponding model!

- Q:How should I find the concentricity of cylindrical roller bearings after installation?

- Any form of assembly, adjustment center is a very troublesome thing, but also in the measuring installation is not very complete, the usual method is to in the base below (or below) thin copper with different thickness, until you feel better, but each installation to re adjust. So, in the machining process, try to use special fixtures and parts drawing in tol and other measures to avoid such a remedy".

- Q:Full use cylindrical roller bearings, uses and advantages?

- Otherwise, due to lack of lubrication and high-speed operation will cause more wear and tear. I am a bearing

- Q:What's the difference between imported bearings and imported bearings?

- The 2 kind of bearing retainer material is mostly copper, and the retainer pin is also copperThere is also a steel retainerImported bearings also have copper and steel

- Q:Cylindrical roller bearingWhat are cylindrical roller bearings, are they available in Kunshan?

- This is the simple cylindrical roller bearing rolling body is cylindrical roller, divided into full (no fixed retainer) and belt retainer 2 categories, because the rolling roller, so the axial bearing capacity relative to the ball bearing to be bigger.

- Q:What is the maximum rotational speed of a single row full cylindrical roller bearing?

- FAG single row full cylindrical roller bearingsFAG single row full cylindrical roller bearings can bear large radial loads, and can also bear single direction axial load. Axial positioning can be guaranteed by a symmetrical arrangement of similar bearings. NCF, 29V, NCF, 30V series of bearings have two fixed inner ring, the outer ring has a baffle, they can only bear the direction of the outer edge of the fixed axial load. The NJ23VH series bearings can bear the axial load toward the inside of the inner ring, and their rollers are fixed in the outer ring, even if the inner ring is taken away. The two rings are tight fit, easy installation and disassembly.

- Q:How to check the thrust cylindrical roller bearings?

- However, in the conventional design, there are few checking bearings, as long as the shaft and shell meet the intensity requirements on the line, because the manufacture of bearings than ordinary mechanical parts to be much more stringent (except shoddy products).If you do your homework, do it according to the design manual.

- Q:What are full cylindrical roller bearings?

- Full capacity roller bearings are divided into double row full load roller, single row full roller, outer spherical roller, CARB bearingsI am a bearing manufacturer, factory direct marketing, welcome inquiry cooperation. Contact information on personal data

- Q:How much is the axial force of double row cylindrical roller bearings? How is it calculated?

- The cylindrical roller bearings have ribs can withstand certain axial force, the axial force for cylindrical but still belongs to the non normal stress, can cause early failure of the bearing, it is generally not given the axial bearing capacity, no formula

- Q:Double row full cylindrical roller bearings, NNCF5008 installation, we need to pay attention to the direction of it?

- Double row cylindrical roller bearings have no directionality, so they do not need to pay attention to the direction! However, it should be noted that the inner ring and outer ring should be positioned separately to prevent axial movement!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bearings four row cylindrical roller FC2028104

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords