Bearings double row cylindrical roller, model NN3032K/YB2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bearings double row cylindrical roller, model NN3032K/YB2

Double row cylindrical roller bearings

The rollers of the double row cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from another

ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing can be easily

mounted and dismounted. Its advantages are obvious especially when there is interference fits

between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer rings

flanges.

- NN double row cylindrical roller bearings

This kind of bearings with inner rid, no outer rid.This assembly part can be separated from another ring, and they have larger radial load capacity than other single row cylindrical roller bearings with the same size, but the axial or housing is free axial displacement, so this kind of bearings can only bear the axial load.

★ Product Features:

The rollers of the cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from

another ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing

can be easily mounted and dismounted. Its advantages are obvious especially when there is

interference fits between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer

rings flanges can bear small steady axial load or great intermittent axial load. It has a high

requirement on the processing of the fitting parts such as axis and housing bore, etc.

★Product Application:

Cylindrical roller bearings are mainly used for:

- Iron and steel metallurgical industry

- medium and large motor

- generator

- combustion engines

- gas tuibine

- machine tool spindle

- speed reducer

- loading and unloading machinery and all kinds of industrial machinery

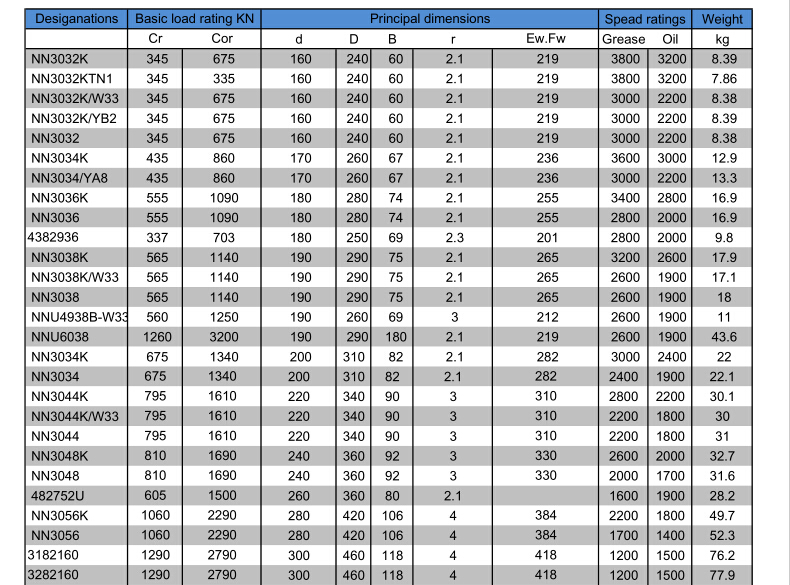

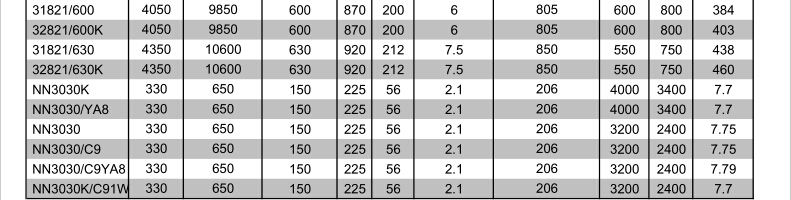

Double Row Cylindrical Roller Bearings Catalogue

- Q:Attention problems of cylindrical roller bearings

- 4, when the interference is large, the oil bath heating or inductor heating bearings can be used to install the heating temperature range of 80 degrees -100 DEG C, the maximum can not exceed 120 degrees centigrade. At the same time, the nut or other appropriate method is used to fasten the bearing so as to prevent the contraction of the bearing in the direction of width and to create a gap between the collar and the shaft shoulder. 5, single row tapered roller bearings installed, the final adjustment should be clearance. The clearance value shall be determined according to the working conditions and the magnitude of the interference fit. Test shall be carried out when necessary. Double row tapered roller bearings and pump shaft bearings have been adjusted for clearance at the factory, and no adjustment is necessary during installation. 6, the bearing should be installed after the rotation test, the first for the rotary shaft or bearing box, without exception, then the power for no load, low speed operation, and then gradually increase as the functioning of the rotation speed and load, and to detect noise, vibration and temperature, abnormal, should stop running and check. The running test is normal and can be used before delivery.

- Q:Can the Nu and N type NJ NUP cylindrical roller bearings bear axial force?

- The answer upstairs is clear. Such bearings can not be designed with axial force. In use, the inner and outer rings of the bearing can have larger axial displacement, and the aim is to compensate the length change caused by the rotating part of the two bearing due to the temperature rise.

- Q:How are the twin row cylindrical roller bearings classified?

- The NN0000K type conical bore double row cylindrical roller bearingThis kind of bearing is compact in structure and bears little deformation under load, so it is suitable for the support of spindle of machine tool. The inner bore of the bearing is taper, and the radial clearance of the bearing can be adjusted slightly.This kind of bearing with no outer wall, so you can install the outer ring and the inner ring assembly respectively (with roller and cage), does not limit the axial displacement of the shaft or shell, cylindrical roller bearing with the same radial size is compared, can bear larger radial load.

- Q:What's the difference between imported bearings and imported bearings?

- Domestic bearings used in the cage and rivet and washer, spacer ring, sealing ring, pillar, pin etc. the material is divided into black metal materials (such as low carbon steel, stainless steel etc.), non-ferrous metal materials (such as brass, bronze and Aluminum Alloy etc.) and non metal materials (such as plastics, phenolic textolite three) etc..Imported bearings are basically the same as those made in China. There are copper, steel, alloy and so on.

- Q:Cylindrical roller and bearing outer ring processing is sheet metal forming?

- Rolling bearings are made by special bearing factories and manufactured by precision special machine tools. It is a highly specialized field in mechanical manufacture. Precision bearings are the key parts to determine the accuracy and operation of the machine. At present, China mainly relies on imports (such as Japan NSK bearings) in high precision bearings.

- Q:My notes is the former has a taper hole on the cone position preload, the latter is a nut. But the online information seems a little different. Are the preload methods for two direction thrust angular contact bearings and angular contact ball bearings the same?

- Dissimilarity! The former is mainly used as the support of the shaft with larger load. The main prevention is the radial runout, which is usually used individually, so there is not much demand for the preload.

- Q:what does that mean? Please enlighten master, thank you.

- Cylindrical roller bearingN216E stands for the bearing retainer as a steel cageN216EM stands for the bearing holder as brass holderThe material of the cage is different (the structure that holds the roller in it for a long time)

- Q:How much is the axial force of double row cylindrical roller bearings? How is it calculated?

- The cylindrical roller bearings have ribs can withstand certain axial force, the axial force for cylindrical but still belongs to the non normal stress, can cause early failure of the bearing, it is generally not given the axial bearing capacity, no formula

- Q:Why are there no double row cylindrical roller bearings in the mechanical design manual?

- but they move axially with the roller and the outer ring?If so, the cylindrical roller bearings without bearings on both sides of the bearing should be normal

- Q:How to calculate the clearance of bearings, such as 23226 double row cylindrical roller bearings

- 1, radial clearance: non preload, bearing radial load, the radial clearance of G for any angle along the radial direction, in the absence of external load relative to the outer ring inner ring from a radial eccentric limit position, move to the opposite limit position of the radial distance arithmetic mean.2, axial clearance: non preload, bearing can withstand axial load in two directions, the axial internal clearance of G: without external load, a ring relative to the other ring, from an axial limit position toward the average axial distance limit position opposite the.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bearings double row cylindrical roller, model NN3032K/YB2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords