Auto-Climbing bracket ACB100 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

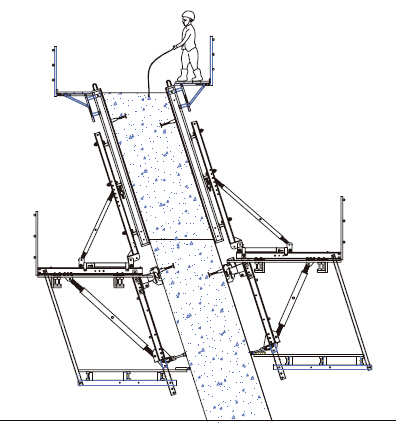

Auto-climbing Bracket ACB100 & ACB50

The power of the auto-climbing formwork is the hydraulic system, which includes the oil cylinder

and two commutators. The commutators can control the climbing of climbing rail and the bracket.

The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily.

Cranes are not needed during the construction. It’s easy to operate, highly efficient and safe. It’s

the best choice for the construction of high buildings and bridges.

There are mainly two types of standard auto-climbing brackets, ACB-50 and ACB-100, the figure

means the push power of cylinder with unit of KN.

Characteristics:

◆ Perfect load bearing anchor system

Anchor system is the most important supporting part. The system is made of five parts shown

below. Thereinto, tensile bolt, V-climbing cone and washer can be taken out for reusing after the

concrete pouring finished.There are two kinds of anchor systems,A & B. A is matched with single

anchor shoe and B is matched with double anchor shoe.

◆ Crane-independent

Crane-independent forming, striking and climbing speeds up the work procedures on the

construction site and also makes them independent of each other. This means the planned

sequences can be maintained along with guaranteeing high productivity levels. The crane can

therefore be used for other tasks.

Hydraulic system is mainly made of two commutators,

oil cylinder and power distribution system.The

commutators can control the climbing of climbing rail

and bracket.

◆ High bearing capacity and safe

The stable working platforms are able to carry large loads, e.g. the storage of reinforcing steel

for the next climbing section. Generously-sized working platforms, the well thought-out design for

handling very high wind loads and the patented control function of the climbing mechanism are

some of the special details contained within the comprehensive safety concept.

◆ Platforms adjusted to suit the angle of inclination

The horizontal working areas thus created provide safe and comfortable conditions for

reinforcement work, shuttering and striking, concreting and finishing.

◆ The ACB formwork system can climb not only vertically but also slantways, the largest angle is

18 degrees.

◆ The system can climb up wholly or separately. The climbing process is steady, synchronous

and safe.

◆ The bracket will not fall to the ground until the construction is finished, the field will be saved

and the impacting breakage will be reduced (especially the panel).

◆ The system will furnish omnidirectional platform, the construction organizations don’t need to

set up additional operation platform.

◆ The error of structure construction is small and easy to correct.

◆ The climbing speed is fast, the construction course will be quickened.

◆ The formwork can climb itself and cleaning work can be done in the same situs , the used times

of tower crane will be greatly reduced.

- Q:What are the considerations when designing steel formwork for dams?

- When it comes to designing steel formwork for dams, there are several important factors that must be taken into consideration. The first and foremost consideration is the structural stability and strength of the formwork. Given the significant forces exerted by dams, it is imperative that the formwork is able to withstand these forces without any deformation or failure. This necessitates a meticulous analysis and design of the formwork system, which includes carefully selecting appropriate steel grades, sizes, and reinforcement. Another crucial aspect to consider is the water pressure that the formwork will be subjected to during the construction and operation of the dam. To maintain the stability and integrity of the dam, it is crucial that the formwork is completely watertight, preventing any leakage or seepage. Special attention should be paid to the joints and connections of the formwork to ensure a tight and secure seal. Durability is yet another factor that must not be overlooked when designing steel formwork for dams. As dams are designed to last for several decades, the formwork needs to be able to withstand prolonged exposure to various environmental conditions, such as temperature fluctuations, moisture, and chemical exposure. It is essential to protect the formwork against corrosion, either by using corrosion-resistant steel or by applying protective coatings. The ease of assembly and disassembly is also an important consideration. Given the complexity of dams and the requirement for precise alignment, it is crucial that the formwork system is designed in a manner that allows for easy and efficient installation and removal. This helps minimize the time and effort required for construction. Lastly, cost considerations play a significant role in the design of steel formwork for dams. The formwork system needs to be cost-effective and efficient, making the most of materials and minimizing waste. Furthermore, the design must take into account the availability and cost of steel, as well as the availability of skilled labor for fabrication and installation. By addressing these factors thoroughly, engineers can ensure the successful construction and long-term performance of dams using steel formwork.

- Q:Can steel formwork be used in areas with limited labor availability?

- Indeed, in areas where labor is scarce, steel formwork can prove to be an invaluable resource. Renowned for its versatility and durability, this system demands less manpower when compared to traditional formwork techniques. Its assembly and disassembly are effortless, and it can be utilized repeatedly, thus diminishing the necessity for constant labor in formwork construction. Moreover, steel formwork's lightweight nature enables easy transportation to remote regions, rendering it ideal for construction endeavors situated in areas where labor resources are limited. All in all, the employment of steel formwork facilitates an expedited construction process and optimizes labor utilization in regions with restricted labor availability.

- Q:What are the different types of finishes available for steel formwork?

- There are several different types of finishes available for steel formwork, each offering unique advantages and characteristics. Some of the most common finishes include: 1. Smooth finish: This is the most basic type of finish, where the steel formwork is left untreated. It provides a clean and smooth surface, making it suitable for applications where a smooth concrete finish is desired. 2. Galvanized finish: Galvanizing involves coating the steel formwork with a layer of zinc to protect it from corrosion. This finish is highly durable and can withstand harsh weather conditions, making it ideal for outdoor applications. 3. Powder-coated finish: Powder coating involves applying a dry powder to the steel formwork and then baking it on. This finish provides a decorative and durable coating that is resistant to chipping, scratching, and fading. It is available in a wide range of colors, allowing for customization. 4. Painted finish: Painting the steel formwork is another common option. It provides protection against corrosion and enhances the aesthetics of the formwork. Different types of paints, such as epoxy or acrylic, can be used depending on the specific requirements of the project. 5. Shot-blasted finish: Shot blasting involves projecting small steel shots onto the surface of the formwork at high velocity. This process removes any impurities, rust, or old coatings, resulting in a clean and textured finish. Shot blasting is commonly used when a rough surface is desired for better adhesion of the concrete. 6. Treated finish: Some steel formwork can be treated with special coatings or chemicals to enhance their properties. For example, anti-stick coatings can be applied to prevent concrete from adhering to the formwork, making it easier to remove after curing. Other treatments may include rust inhibitors or fire-resistant coatings. The choice of finish for steel formwork depends on various factors such as the intended use, environmental conditions, desired aesthetics, and budget. Consulting with a professional or manufacturer can help determine the most suitable finish for a specific project.

- Q:How does steel formwork affect the overall carbon footprint of the project?

- Steel formwork can have a significant impact on the overall carbon footprint of a construction project. Firstly, steel production itself is a highly energy-intensive process, requiring the use of fossil fuels and emitting substantial amounts of greenhouse gases. The extraction and processing of raw materials, such as iron ore and coal, contribute to the carbon emissions associated with steel production. Additionally, the transportation of steel formwork to the construction site also contributes to the carbon footprint. Steel is a heavy material, requiring large amounts of fuel for transportation, especially if the site is far away from the manufacturing facility. The emissions from transporting steel formwork can further add to the project's carbon footprint. Moreover, the lifespan and durability of steel formwork play a crucial role in its overall environmental impact. If the steel formwork is only used for a single project and then discarded, it adds to waste generation and the need for additional production and transportation of new formwork for subsequent projects. This cycle of production and disposal increases the carbon emissions associated with the project. However, steel formwork does offer some sustainability benefits that can offset its carbon footprint. Steel is a highly recyclable material, and using recycled steel in the production of formwork reduces the need for new steel production and associated carbon emissions. Additionally, steel formwork's durability allows for multiple uses, reducing waste generation and the carbon emissions associated with disposal and replacement. In conclusion, while steel formwork can contribute to the overall carbon footprint of a project due to the energy-intensive production process, transportation emissions, and potential waste generation, its recyclability and durability provide opportunities to mitigate these impacts. Proper management and recycling practices can help minimize the carbon emissions associated with steel formwork and make construction projects more environmentally sustainable.

- Q:Can steel formwork be used for precast concrete facades with intricate patterns?

- Absolutely! Precast concrete facades with intricate patterns can indeed utilize steel formwork. Renowned for its robustness and longevity, steel formwork proves ideal for fashioning elaborate and meticulous designs. The adaptability of steel enables the crafting of intricate patterns, textures, and contours on the concrete surface. Moreover, steel formwork can be effortlessly tweaked and altered to accommodate any desired pattern or design, rendering it a favored option for precast concrete facades that demand intricate patterns or artistic elements. Ultimately, steel formwork offers the vital support and flexibility necessary to accomplish intricate designs in precast concrete facades.

- Q:Can steel formwork be easily modified or adjusted during concrete placement?

- Concrete placement can easily incorporate modifications or adjustments when using steel formwork. The versatility and flexibility of steel formwork enable effortless modifications or adjustments according to the needs of the concrete structure. Steel formwork systems typically consist of adjustable components like panels, beams, and props, which can be readily repositioned or relocated to accommodate changes in the design or dimensions of the concrete structure. These adjustable components can be swiftly and securely locked in place, ensuring stability and support during concrete placement. Moreover, steel formwork facilitates the utilization of various formwork accessories like clamps, connectors, and ties, further enhancing its adaptability and ease of modification. In summary, steel formwork offers a highly efficient and flexible solution for adjusting or modifying formwork during concrete placement.

- Q:Can steel formwork be used for precast concrete tanks?

- Yes, steel formwork can be used for precast concrete tanks. Steel formwork offers strength, durability, and flexibility, making it suitable for constructing various types of precast concrete structures, including tanks.

- Q:What are the common design considerations for steel formwork in earthquake-prone areas?

- In earthquake-prone areas, the design considerations for steel formwork are crucial to ensure the safety and stability of structures during seismic events. Some common design considerations for steel formwork in earthquake-prone areas include: 1. Material Strength: The steel used in formwork should have high tensile strength to withstand the lateral forces generated during an earthquake. High-strength steel, such as Grade 60 or Grade 80, is commonly used in earthquake-resistant formwork designs. 2. Reinforcement: The formwork should be adequately reinforced to enhance its rigidity and resistance to seismic forces. Additional reinforcement can be provided by adding steel braces, cross-bracing, or diagonal members to increase the structural integrity of the formwork system. 3. Connection Details: The connection details between different formwork elements should be designed to withstand the dynamic forces induced by earthquakes. Welded or bolted connections are commonly used, ensuring that they have adequate strength and ductility to resist seismic loads. 4. Stiffness and Flexibility: The formwork system should exhibit an appropriate balance between stiffness and flexibility. It should be rigid enough to resist lateral forces during an earthquake but also flexible enough to absorb and dissipate seismic energy without collapsing. 5. Anchorage Systems: Anchorage systems are crucial in securing the formwork to the foundation or supporting structure. These systems should be designed to resist the uplift and lateral forces generated during an earthquake and prevent the formwork from overturning or sliding. 6. Diaphragm Action: To enhance the overall structural performance, the formwork system should be designed to provide diaphragm action. This means that the formwork acts as a continuous and rigid panel transferring forces across its surface, thereby reducing localized stresses and improving the overall stability of the structure during an earthquake. 7. Formwork Compatibility: The steel formwork should be compatible with other structural elements, such as concrete columns, beams, and slabs. It is essential to ensure that the formwork system can adequately transfer the loads from the concrete to the supporting structure without compromising its stability or integrity during seismic events. 8. Construction Practices: In addition to design considerations, proper construction practices play a vital role in ensuring the effectiveness of steel formwork in earthquake-prone areas. Adequate bracing and temporary supports should be used during formwork assembly to maintain stability and prevent collapse before the concrete is poured and hardened. By considering these design considerations, engineers and designers can develop robust steel formwork systems that can withstand the forces exerted by earthquakes and ensure the safety of structures in seismic regions.

- Q:Are there any specific considerations for using steel formwork in areas with limited space?

- Yes, there are several specific considerations for using steel formwork in areas with limited space. Firstly, the dimensions of the steel formwork system should be carefully chosen to ensure that it can fit into the available space. This includes considering the height, width, and depth of the formwork components, as well as any necessary clearances for movement and installation. Secondly, the assembly and disassembly of the steel formwork system should be carefully planned to minimize the space required. This may involve using smaller formwork panels or modular systems that can be easily transported and maneuvered in tight spaces. Additionally, the sequencing of formwork removal should be considered to ensure that there is enough space for workers and equipment to safely access the area. Thirdly, the storage of steel formwork components when not in use should be taken into account. In areas with limited space, it may be necessary to stack the formwork panels vertically or utilize compact storage solutions to maximize space efficiency. Lastly, the accessibility of the construction site should be considered. In areas with limited space, it may be challenging to transport and deliver the steel formwork components. It is important to evaluate the availability of access roads, parking areas, and equipment staging areas to ensure that the steel formwork can be safely and efficiently delivered to the construction site. Overall, using steel formwork in areas with limited space requires careful planning and consideration of the dimensions, assembly, disassembly, storage, and site accessibility. By addressing these specific considerations, it is possible to effectively utilize steel formwork systems in tight spaces while ensuring the safety and efficiency of the construction process.

- Q:How does steel formwork contribute to the overall fire safety of the building?

- The inherent properties and characteristics of steel formwork make it a valuable asset in enhancing the fire safety of a building. Firstly, steel formwork is renowned for its exceptional fire resistance. Its high melting point and resistance to ignition and burning make it a suitable choice for construction in fire-prone areas. In case of a fire, steel formwork remains structurally stable, serving as a vital barrier that contains the fire and prevents its spread to other sections of the building. This is particularly crucial in tall buildings where fire safety is of utmost importance. Furthermore, steel formwork is non-combustible, thereby minimizing the release of flammable gases and toxic fumes when exposed to fire. This is essential for the safety of occupants as smoke inhalation and toxic gases are leading causes of casualties in fire incidents. The utilization of steel formwork reduces the risk of smoke and toxic gases permeating throughout the building, allowing occupants more time to evacuate safely. Moreover, steel formwork is a durable and robust material capable of withstanding the impact of fire while retaining its structural integrity. This is vital in ensuring the stability of the building during a fire, preventing collapse, and reducing the likelihood of injuries or fatalities. Steel formwork can also resist the effects of high temperatures, such as thermal expansion, further contributing to the fire safety of the building. In conclusion, steel formwork plays a crucial role in enhancing the overall fire safety of a building. Its high fire resistance, non-combustible nature, and durability help contain fires, minimize the spread of smoke and toxic gases, and maintain the structural integrity of the building. By incorporating steel formwork into construction, the risk of fire-related incidents and their potential consequences can be significantly reduced, ensuring the safety of occupants and property.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Auto-Climbing bracket ACB100 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products