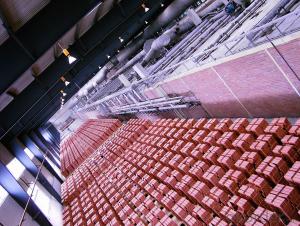

ACC Panel production line with Capacity of 100,000m3

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Our AAC plant adopts Germany technology.

Capacity: 100,000m3-300,000m3

Full automation or Semi automation

high quality

We produce 4.0m, 4.2m, 4.8m, and 6m series of high capacity AAC production line for Middle East, Africa and South-east of Asia, etc. The Whole set of Aerated-Concrete equipment we produced have become universal products for domestic new or existing aerated factories. AAC blocks will become dominate wall materials in future.

Application Scope: AAC block producing

Feature

The operation of our plant is simple and pratical.

Waste materials and water can be recycled during operation process, it is environment-friendly.

The whole equipment has higher degree of automation.

The final products are high in precision, qualified product rate ≥ 98%.

Our AAC plant has good cost performance.

Production Process:

1.Stocking and supplying raw materials

2.Processing raw materials

3.Batching and pouring

4.Cutting

5.Grouping and maintaining process

6.Steaming in autoclaves

7.Final products packaging

Product Principle

1) Technology Orientation

Production and application of aerated concrete has a history more than 40 years in China. Viewing from technology point, high quality products can use 3mm special sand slurry technology to meet the construction requests and 50% energy saving goals. (When mortar joint is less than 3mm, take thermal conductivity coefficient of wall as 1; when mortar joint is more than 3mm, take thermal conductivity coefficient of wall as 1.5). Based on the history of the aerated concrete development, only high quality products can bring a prosperous market. Thus, the technology orientation of this scheme is high-class products according to China Standard GB11968-2006.

2) Production Capacity

In our factory, the main production capacity is annually 50,000m3, 100,000m3, 150,000m3, 200,000m3, 300,000m3 etc. The product is aerated concrete block which is light in weight. Also, there is a reservation of plate in consideration of users' need.

3) Product Specification

Products conform to requirement of 04~07 grade blocks stated in GB11968-2006.

General Specifications of Aerated Concrete Blocks

Service

1.Production Line Design.

Including: drawing of plant working process , drawings of land construction, drawings of power working, drawings of driving force for working, drawings of anti-dust, drawings of water supply and drainage, and drawing of air pipeline construction.

2.Technical Guidance of Building Factory

Including: consultation of facility, Equipment installation guide, constitution the production preparation, etc.

3.Providing the technical information of setting up factory

Including: part of the factory management system, all posts accountability of production line, process rules, safety rules, setting a quota of staff and posts, pre-production tools directory, laboratory instruments, product catalogs, and test methods.

FAQ:

1. Where is your factory located?

Our factory is located in Jiangsu Province. It is close to Shanghai Port.

2. What are your advantages compared with others?

CNBM is the largest manufacturer and supplier of building materials and machinery in China. We are directly under control of State-owned Assets Supervision and Administration Commission of China. We have more 20 engineers who are engage in quality inspection, and more than 50 employees who are in charge of logistic. Our products are manufactured under ISO quality control system.

3. Which countries does your plant export to?

Our production line has been installed in the Middle East, Africa. India and so on.

- Q:Brick machine operating procedures

- Check the electrical part of the fault and leakage phenomenon. Check if the packing concentration is appropriate. Check the triangle belt tightness is appropriate. After the motor is fed to the upper part of the cylinder, open the material gate, so that the material flow to the feeding body cylinder, at this time presses began to work.

- Q:Brief introduction of the brick machine

- The purpose of the utility model is to overcome the above shortcomings and provide an integrated hydraulic brick making machine which solves the problems of the existing brick making machine when the noise is large, the power consumption is high, the auxiliary tools are needed and so on.

- Q:Maintenance method of fly ash brick machine

- the quality of personnel to participate in maintenance is low, can not follow the maintenance of the operating procedures, there is no corresponding maintenance records.

- Q:Automatic concrete brick machine bearing how to choose?

- to avoid the pressure plate loose, the plate hammer reveals the rotor body, and the body impact, damage the machine. The following are the same as the "

- Q:What kind of configuration does the small semi-automatic cement brick machine include?

- Dosing Machine 2, Cement Warehouse 3, Cement Metering 4, Screw Conveyor 5, Base Material Mixer 6, Pigment Mixer 7, Bottom Belt Conveyor 8, Pigment Belt Conveyor 9, Elevated Horizontal Belt Conveyor 10

- Q:Hollow block brick brick machinery in use should pay attention to what the problem to ensure the normal operation of the brick machine?

- Fourth: the daily clean up the mold, the use of air compressor, soft tools to remove concrete residue, is strictly prohibited grappling, pry scraping mold;

- Q:The development of brick machine

- 1, ingredients machine. Using computer control, according to the selection of different raw materials, enter a recipe menu for automatic measurement, and then transfer the material into the mixer;

- Q:Cement brick machine brick machine advantages

- Cement hollow brick machine with the current characteristics of similar domestic and foreign markets and the need to design and manufacture of new brick equipment.

- Q:Installation and commissioning of hydraulic press

- If the machine needs to be removed due to transport needs can be divided into forming device, delivery device, feeding device, brick device, palletizing device, phase control device, installation according to the assembly relationship in place.

- Q:How can a free brick brick brick machine be classified?

- According to the structure of the block: divided into a back cover block, not the back of the block, slot block, a slot block.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ACC Panel production line with Capacity of 100,000m3

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products