Roller crusher of brick making production line with best quality and excellent price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

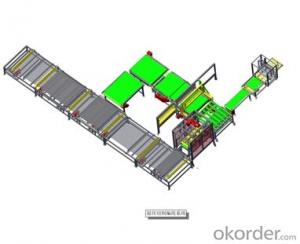

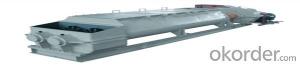

Roller crusher is mainly used to crush the raw materials such as gangue, industial waste, clay and other materials. It is an ideal raw material handling machine.The rollers of GS120X120 and GS120x100 are imported from Germany to increase service life.

Technical parameters:

Production capacity (m3/h): ≥45

Inlet grain hardness (Moh’s hardness): ≤4

Water content of inlet material: ≤16%

- Q:Brief introduction of the brick machine

- A multi-purpose machine, no pallets, a stacking. The utility model products can produce a variety of tiles within a meter, hexagonal brick, lawn brick, slope protection brick, Curb, from raw materials to finished products are fully automatic, simple operation.

- Q:What is the difference between a vacuum brick machine and an ordinary brick machine?

- In the water, because the vacuum brick machine is the first vacuum and water re-sintering, natural than ordinary brick coal time is short, forming fast.

- Q:Where is the brick of the tiles used to make the brick better?

- can absorb moisture and heat, adjust the surface of the local space temperature and humidity, the regulation of urban microclimate, ease the effect of urban heat island has a greater role 3, can reduce the city drainage and flood control pressure, to prevent public waters pollution and sewage treatment

- Q:Automatic concrete brick machine bearing how to choose?

- When the fully automatic concrete brick making machine is running, it should always check whether the bearing seal of the equipment is. The grease in the bearing seat should be filled once every month. Every three months should be cleaned and replaced with oil frying. Normal after feeding, feeding together to be uniform, should be avoided mixed with iron hard objects;

- Q:Burning brick and autoclaved lime sand brick what different

- Autoclaved lime sand brick (standard brick) is made of fly ash or other slag or lime as raw material, adding lime, gypsum and aggregate, prepared by embryo material, pressed molding, high efficiency steam curing and other processes.

- Q:Hollow block brick brick machinery in use should pay attention to what the problem to ensure the normal operation of the brick machine?

- Fifth: replace the mold, clean, oil rust, should be set to dry, flat at the support pad flat to prevent gravity deformation.

- Q:The development of brick machine

- Its environmental protection and energy conservation, the new wall by the country's affirmation.

- Q:Fly ash Mianshao brick machine is not a kind of construction waste with coal ash to do brick, who understand this thing?

- No burning brick without sintering, natural conservation, room temperature steaming can be. The equipment produced by the finished product burning brick to meet the building materials industry brick standard, is the comprehensive utilization of waste residue, eliminate environmental pollution, save land resources, promote urban and rural labor employment, fortune ideal equipment. The main equipment is Mianshaozhuanji, which is commonly known as the brick machine or brick machine, is the production of Mian Shaozhuan the main equipment, mainly divided into turntable, vacuum extruder and automatic hydraulic molding machine.

- Q:Installation and commissioning of hydraulic press

- The factory of the machine in accordance with the relevant provisions of the factory have made the factory test, but due to long-distance transport and a long time to place and other reasons, the installation of hydraulic brick should be the following checks:

- Q:Brief introduction of cement brick machine

- Can be said to invest less, quick, is a lot of investors to invest in the popular industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roller crusher of brick making production line with best quality and excellent price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products