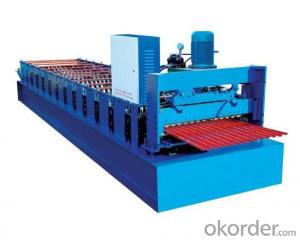

4Hi Non-Reversible Cold Roll Mill Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

4Hi Non-Reversible Cold Roll Mill is made of Carbon steel, C-Mn steel, alloy structure steel, alloyed tool steel, cold roll steel, steel for pressure vessel, carburizing steel, die steel, stainless steel and so on. For blank, with iron frame; For semi-finish and finish products, painted with antirust oil, packed with plastic film and packaged into a wooden case. Package is upon your request.

Scope of Application of the Equipment:

4Hi Non-Reversible Cold Roll Mill mainly used for pipeline, wind tower, and works with a concrete placing boom in concrete pumping. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure. This equipment can only be used in concrete construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The equipment is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Product Advantages:

1. Good mechanical properties;

2. High tensile strength;

3. Well-closed formation;

4. Comparative price;

5. High-quality production;

6. Customized services, manufacturing according to your specific requirements.

Main Product Features:

1,The small model is light, easy to move, suitable for small construction projects;

2,The full hydraulic system can extend component life, improve equipment reliability, reduce the failure rate and reduce maintenance costs;

3,The S tube valve are cast into shape with austenitic manganese steel and has the dual advantages of anti-high pressure and anti-wearing;

4,Main electric elements are from Schneider and LG company, the reliability of the electric-control system is highly approved;

5,Glasses plates and cut loops are made of anti-wearing horsiness alloy, they have long service life;

6,The lubrication system adopts progressive distributor which supplies every lubrication point with oil in turn, and the oiling time can be set to save oil.

Product Specifications:

Wind Turbine Shaft | 42CrMo4, 34CrNiMo6 |

Marine Shaft | C-Mn steel |

Hydro Turbine Shaft | 20SiMn |

Roller Shaft | 70Cr3Mo; 9Cr2Mo; MC1; MC2; MC3 |

Gear Shaft | 17CrNiMo6; 18CrNiMo7-6; 20CrNi2Mo; 42CrMo; 47CrNiMo6, 20CrMnMo |

Gear | 17CrNiMo6; 18CrNiMo7-6; 20CrNi2Mo; 42CrMo; 47CrNiMo6, 20CrMnMo, 30 CrNiMo6 |

Pressure Vessel Forgings | SA105, SA350 LF2, 16Mn, 20MnMo, 15MnMo, 12Cr2Mo1, 14Cr1Mo, 42CrMo, F304, F316, 17-4PH, 4330, 4336, 4340 |

Ring Rolling | 16Mn, 50Mn, 42CrMo, 15MnV, 35CrMo, A105, 20#, 304, 304L, 316, 316L |

FAQ:

Q1: How many kinds of 4Hi Non-Reversible Cold Roll Mill you have?

A1: We have all kinds of Cold Roll Mill such as small models with capacity 20, 25, 30,40m3/h, medium models with capacity 40, 50m3/h, large models with capacity 60, 803/h.

Q2: Do you have concrete spare parts that could be working together with concrete pump?

A2: Yes, We have below series.

1: 12/15/18m Manual Mechanical Spider Concrete Placing Booms

2: 13/15/17/18m Mobile Hydraulic Spider Concrete Placing Booms

3: 28/32m Floor Climbing Type and Elevator Well Shaft Climbing Concrete Placing Booms (Tubular Column)

Q3: What is the Delivery Status?

A3: N+T (Normalizing + Tempering), Q+T (Quenching + Tempering);

Q4: Is engineer available for training and after sales service?

A4: Yes, our oversea engineer’s team is standing by for oversea service. Some engineers could speak English.

Q5: What is the Production Process?

A5: Forging---heat treatment---machining (rough machining and finish machining).

- Q:What gear is machined out of the gear?

- This cutting method is simple, do not need special machine tools, but the productivity is low, low precision, it is only applicable to single or small batch production and precision requirements of the gear processing is not high.

- Q:Main classification of hydraulic machinery?

- (3) according to the degree of precision equipment according to the degree of precision, hydraulic equipment can be divided into precision equipment and general equipment.

- Q:What are the shortcomings of traditional machining?

- Low efficiency, high cost, batch processing, then the processing quality is not stable, the accuracy is not high, labor intensity, processing staff, frequent processing times, and now good equipment to complete the car, drilling, milling and other processes.

- Q:What is the principle of the cutting order in machining?

- ③ the first main after the first processing of the main surface, and then processing the secondary surface.

- Q:Information on building materials decoration.

- What are the building materials industry? Wallpapers Flooring Pallet Handling Machinery Fireproof Materials Waterproof and Moistureproof Materials Heat Absorbing Sound Absorbing Materials Pipe Fittings Concrete and Products Activities Furniture Manufacturing Machinery Building Materials Processing Building Glass Construction Related Equipment Construction Project Cooperation Adhesive Metal Building

- Q:Mechanical processing technology to mechanical product design, specifically to prepare what?

- Do the design to lay the foundation: skilled use of design software, design products and the actual convergence (production costs, easy to use, security, etc. should have a specific audit).

- Q:Classification and components of hydraulic press

- according to the degree of precision equipment according to the degree of precision, hydraulic equipment can be divided into precision equipment and general equipment.

- Q:What are the aspects of the mechanical processing quality

- Parts of the processing quality is to ensure that the basis of mechanical product quality. The processing quality of the parts, including the machining accuracy of the parts and the processing of the surface quality, are two major aspects

- Q:Information on building materials decoration.

- Equipment Construction Projects Cooperation Adhesives Metal Building Materials Insulation Materials Building Materials Door and Window Wall Materials Wood Sheet Other Building Materials Products Construction Materials Stone Stone Lime, Gypsum Plastic Building Materials Locks Ceramic Processing Machinery

- Q:What are the oyster processing companies?

- printed posters printing desk calendar printing calendars printing business cards printing envelopes printing paper printing stickers printing other commercial printing processing books printing processing paper processing 2 processing laser plus .. The

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

4Hi Non-Reversible Cold Roll Mill Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products