304 2B Stailess Steel Sheet cold rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Cold Rolled 304 2B Stailess Steel Sheet

Type | Cold Rolled 304 2B Stailess Steel Sheet |

Thinckness | Cold rolled:0.3mm-3mm Hot rolled: 3.0mm-150mm |

Widthness | 1000-2000mm or as customized |

Length | 1000mm-6000mm |

Finish | 2B, BA, HL, MIRROR, NO. 1-NO. 4, 8K, and so on. |

Standard | ASME, ASTM, EN, BS, GB, DIN, JIS etc |

Material | mainly:201, 202, 304, 304L, 316, 316L,316 300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,3 200series:201,202,202cu,204 400series:409,409L,410,420,430,431,439 |

Application range | Decoration Industry Kitchenwave Building Elevator Upholstery |

Delivery time | 10-15 days subject to the clients' requirement and quantity |

Productivity | 3000 tons/month |

Note | We can produce other standard as the customers’ requirement |

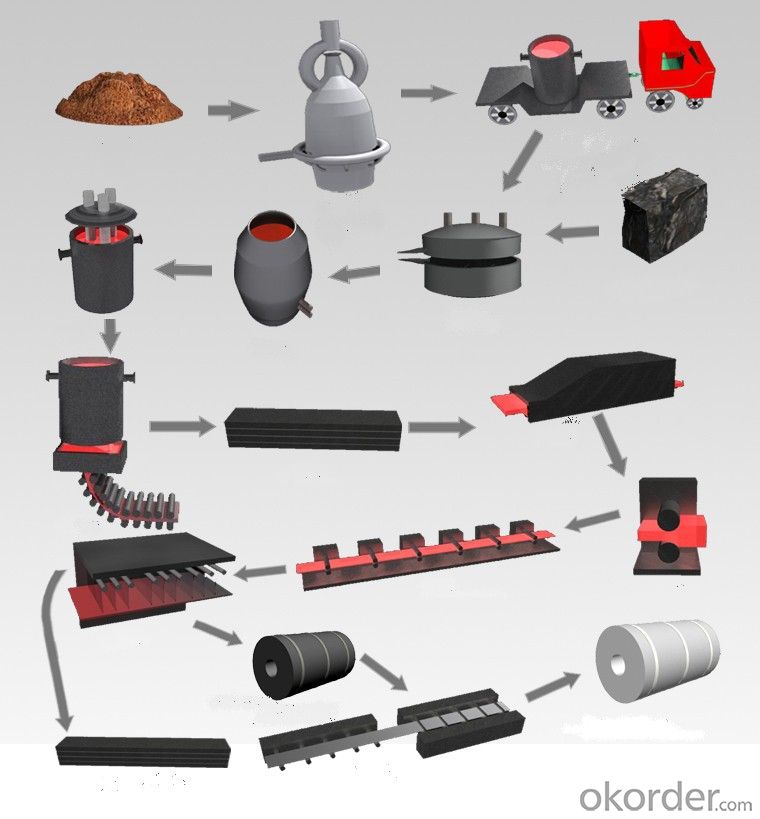

Production Flow

Simple production process of stainless steel plate production

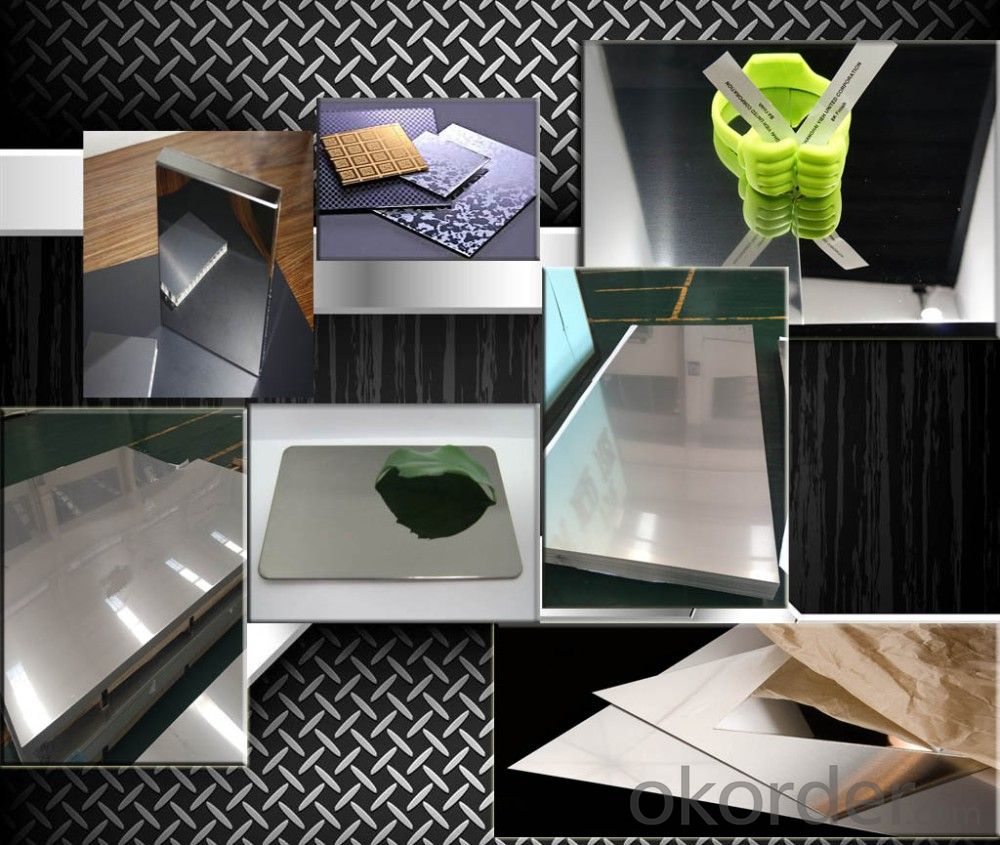

1.GRINDING

Grinding finish, also called brushed, directional or satin finish. coil or sheet...

2.POLISHING

polished stainless steel sheet uses grinding fluid to polish by polishing equipment on stainless steel ..

3.PVD COLOR COATING

PVD means Physical Vapor Deposition,working in vacuum condiction.....

4.ETCHING

Etching is corrode different kinds of patterns on stainless steel surfaces by chemical methods.

5.EMBOSSING

It is physical rolling on the stainless steel surface, pattern comes from metal roller...

Applications

Applications

Be extensively applied to architectural decoration, such as elevator decoration, luxurious doors, outdoor projects, wall decoration, advertisement nameplates, sanitary ware, ceiling, corridor, hotel hall, shop facade.Kitchenware, food industry, electronic industry, medical equipment, etc.

Chemical Compositon and Physical Property:

| Type | Chemical Composition (%) | |||||

| 410 | C | SI | Mn | S | P | Cr |

| 0.03 | 0.32 | 0.25 | 0.001 | 0.019 | 12.21 | |

- Q:Can stainless steel sheets be used for water filtration systems?

- Yes, stainless steel sheets can be used for water filtration systems. Stainless steel is commonly used in water filtration due to its excellent corrosion resistance and durability. It is able to withstand high pressure, temperature variations, and exposure to different chemicals, making it suitable for long-term use in water filtration applications. The smooth surface of stainless steel sheets also facilitates easy cleaning and prevents the accumulation of bacteria and other contaminants. Additionally, stainless steel is a non-reactive material, meaning it does not release any harmful substances into the filtered water, ensuring its safety for consumption. Overall, stainless steel sheets are a reliable and effective choice for water filtration systems.

- Q:What is the process of stainless steel mirror panel? What's the difference between them and stainless steel sand blasting plates?

- Stainless steel sand blasting plates are painted on stainless steel sand blasting plates. Stainless steel sand blasting plate refers to the use of zirconium beads through the mechanical equipment in the stainless steel plate processing, so that the surface of the board presents small beads, grainy sand surface, forming a unique decorative effect. Stainless steel sand blasting decorative board uses: mainly used in architectural decoration, elevator decoration, industrial decoration, facilities decoration and other stainless steel products.

- Q:Do stainless steel sheets have a warranty?

- Yes, stainless steel sheets generally come with a warranty. The duration and terms of the warranty may vary depending on the manufacturer and the specific product. It is always recommended to check with the supplier or manufacturer for the details of the warranty coverage. Typically, the warranty covers defects in material or workmanship and provides a replacement or repair of the stainless steel sheet if any issues arise within the specified warranty period. It is important to follow the manufacturer's care and maintenance instructions to ensure the validity of the warranty.

- Q:How do you determine the weight of a stainless steel sheet?

- To determine the weight of a stainless steel sheet, you need to consider its dimensions, thickness, and density. The first step is to measure the length, width, and thickness of the sheet using a measuring tool such as a ruler or caliper. Make sure to measure in the same unit of measurement, such as inches or millimeters, to ensure accuracy. Next, you need to determine the density of stainless steel. Stainless steel has a density of around 7.9 grams per cubic centimeter (g/cm³) or 7900 kilograms per cubic meter (kg/m³). This value may vary slightly depending on the specific grade or alloy of stainless steel being used. Once you have the dimensions and density, you can calculate the weight using the formula: weight = volume × density. To find the volume, multiply the length by the width and the thickness. For example, if you have a stainless steel sheet that measures 1 meter by 1 meter and has a thickness of 2 millimeters, the volume would be 0.001 cubic meters (1m x 1m x 0.002m). Using the density of stainless steel (7900 kg/m³), you can then calculate the weight by multiplying the volume by the density. In this example, the weight of the stainless steel sheet would be 7.9 kilograms (0.001m³ x 7900 kg/m³). It is important to note that this calculation will provide an approximate weight as it assumes a uniform thickness throughout the entire sheet. Additionally, variations in composition or manufacturing processes may lead to slight deviations in the density of the stainless steel, which can affect the accuracy of the weight calculation.

- Q:Can stainless steel sheets be used for medical instruments?

- Yes, stainless steel sheets can be used for medical instruments. Stainless steel is a popular choice for medical instruments due to its excellent corrosion resistance, durability, and ease of sterilization. It is non-reactive, which means it does not leach any harmful substances into the body during medical procedures. Stainless steel sheets are used to manufacture various medical instruments such as surgical tools, implants, dental instruments, and diagnostic equipment. The smooth surface of stainless steel sheets also makes them easy to clean and maintain, which is crucial for maintaining sterility in medical settings. Overall, stainless steel sheets are a reliable and widely used material for manufacturing medical instruments.

- Q:How do you bend stainless steel sheets?

- To effectively bend stainless steel sheets, a combination of skill, knowledge, and the right tools is necessary. Follow these steps for successful bending: 1. Identify the specific grade of stainless steel you are working with as each grade possesses unique characteristics affecting malleability and bending response. 2. Prior to bending, ensure the stainless steel sheet is clean and devoid of any dirt or debris. Use a mild detergent and a soft cloth for surface cleaning. 3. Mark the precise bending line by measuring and indicating the desired spot. Utilize a ruler or straight edge for accuracy. 4. Select an appropriate bending tool based on the size and thickness of the stainless steel sheet. Options include a press brake, rolling machine, or bending machine. 5. Gradually apply pressure by placing the stainless steel sheet in the bending tool, aligning it with the marked bending line. Avoid excessive force to prevent cracking or deformation. 6. Adjust the bending angle as needed by repositioning the stainless steel sheet within the bending tool. Utilize the tool's adjustments or supplementary tools like clamps for precise angles. 7. Inspect the result by carefully removing the stainless steel sheet from the bending tool. Check for defects, cracks, or unevenness. Minor adjustments can be made using a rubber mallet or a hammer with a soft face. Keep in mind that bending stainless steel sheets requires practice and precision. Begin with smaller projects and gradually advance to more complex bends. If uncertain or lacking experience, consult a professional in metal fabrication for the best outcomes.

- Q:How do stainless steel sheets differ from regular steel sheets?

- There are several key differences between stainless steel sheets and regular steel sheets. Firstly, stainless steel is an alloy that contains a minimum of 10.5% chromium by mass. This chromium content creates a protective passive layer on the steel's surface, preventing corrosion and staining. On the other hand, regular steel sheets are prone to rust and corrosion when exposed to moisture or certain chemicals. Secondly, stainless steel sheets have superior resistance to heat and oxidation compared to regular steel sheets. This makes stainless steel an excellent choice for applications that require high temperature resistance, like industrial furnaces or automotive exhaust systems. Thirdly, stainless steel sheets have exceptional strength and durability, making them suitable for various structural and industrial uses. Regular steel sheets may have lower strength and durability, depending on their composition and manufacturing process. Moreover, stainless steel sheets have an appealing appearance due to their smooth and shiny surface. This aesthetic quality makes them a popular choice in architectural, interior design, and decorative applications. Lastly, stainless steel sheets are known for their hygienic properties. They are non-porous and easy to clean, making them commonly used in industries with strict hygiene requirements, such as food processing, pharmaceuticals, and healthcare. In conclusion, stainless steel sheets differ from regular steel sheets in terms of their corrosion resistance, heat resistance, strength, appearance, and hygiene properties. These unique characteristics make stainless steel sheets the preferred material for many industries and applications.

- Q:Are stainless steel sheets suitable for outdoor furniture?

- Yes, stainless steel sheets are highly suitable for outdoor furniture. Stainless steel is known for its exceptional durability and resistance to corrosion, making it an ideal material for withstanding outdoor elements such as rain, sunlight, and temperature changes. Stainless steel sheets are also easy to clean and maintain, requiring minimal effort to keep them looking new. Additionally, stainless steel has a sleek and modern appearance that can enhance the aesthetic appeal of outdoor furniture. Overall, stainless steel sheets offer the perfect combination of strength, longevity, and visual appeal, making them a great choice for outdoor furniture.

- Q:Are stainless steel sheets suitable for storage tanks?

- Yes, stainless steel sheets are suitable for storage tanks. Stainless steel is a highly durable and corrosion-resistant material, making it an ideal choice for storing various substances. It offers excellent resistance to rust and corrosion, ensuring that the tank remains intact and free from leaks. Stainless steel also has a high strength-to-weight ratio, allowing for the construction of large storage tanks without sacrificing structural integrity. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for storing food-grade or pharmaceutical substances. Overall, stainless steel sheets are a reliable and long-lasting option for storage tanks in various industries.

- Q:Can stainless steel sheets be used for food processing?

- Yes, stainless steel sheets are commonly used in food processing due to their excellent corrosion resistance, durability, and ease of cleaning. They do not react with food, making them safe for use in various food processing applications such as food preparation surfaces, equipment, and storage containers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

304 2B Stailess Steel Sheet cold rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords