3 Tons Battery Powered Forklift CPD 30C

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

An important aspect of forklift operation is that most have rear-wheel steering. While this increases maneuverability in tight cornering situations, it differs from a driver’s traditional experience with other wheeled vehicles. While steering, as there is no caster action, it is unnecessary to apply steering force to maintain a constant rate of turn.

Another critical characteristic of the forklift is its instability. The forklift and load must be considered a unit with a continually varying center of gravity with every movement of the load. A forklift must never negotiate a turn at speed with a raised load, where centrifugal and gravitational forces may combine to cause a disastrous tip-over accident. The forklift are designed with a load limit for the forks which is decreased with fork elevation and undercutting of the load (i.e., when a load does not butt against the fork "L"). A loading plate for loading reference is usually located on the forklift. A forklift should not be used as a personnel lift without the fitting of specific safety equipment, such as a "cherry picker" or "cage".

Forklifts are a critical element of warehouses and distribution centers. It’s imperative that these structures be designed to accommodate their efficient and safe movement. In the case of Drive-In/Drive-Thru Racking, a forklift needs to travel inside a storage bay that is multiple pallet positions deep to place or retrieve a pallet. Often, forklift drivers are guided into the bay through guide rails on the floor and the pallet is placed on cantilevered arms or rails. These maneuvers require well-trained operators. Since every pallet requires the truck to enter the storage structure, damage is more common than with other types of storage. In designing a drive-in system, dimensions of the fork truck, including overall width and mast width, must be carefully considered.

Forklift control and capabilities

Forklift hydraulics are controlled either with levers directly manipulating the hydraulic valves, or by electrically controlled actuators, using smaller "finger" levers for control. The latter allows forklift designers more freedom in ergonomical design.

Hydraulic elevator for tractors

Forklift trucks are available in many variations and load capacities. In a typical warehouse setting most forklifts have load capacities between one and five tons. Larger machines, up to 50 tons lift capacity, are used for lifting heavier loads, including loaded shipping containers.

A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations. In 2013 alone the top 20 manufacturers worldwide posted sales of $30.4 billion with 944,405 machines sold.;and the U.S. forklift market was nearly $33 billion.

Each individual state and territory issue licences in their own jurisdiction, including what is known as "high risk work licences" for high risk work. Forklift licences are classed as "high risk work licences".

To obtain a forklift licence in any State or Territory an applicant must undertake a training course with an approved training organisation and then, on completion of the course, apply to the appropriate State or Territory for a forklift licence. There is a fee attached which varies from jurisdiction to jurisdiction.

Forklift licences issued in one jurisdiction are recognized in all. Licence cancellation in one jurisdiction is also recognized in all.

Forklift Specification:

Model | CPD30C | |

Load capacity kg | 3000kg | |

Load center mm | 500mm | |

Power type | Battery | |

Max.lifting speeds | 290mm/s | |

(with load)mm/s |

| |

Max.Driving speeds | 14/16km/h | |

(with without load)km/h |

| |

Max.Towing speeds | 13kN | |

(with load)kN |

| |

Gradeability(with load)% | 15% | |

Lifting height mm | 3000mm | |

Free lift mm | 80mm | |

Tilting angles |

| |

Min. turning radius mm | 2350mm | |

Min. right angle aisle width mm | 2280mm | |

Min. under-clearance mm | 140mm | |

Dimensions | A Overall length (inincluding fork) mm | 3705 |

B Overall width mm | 1240 | |

H Overall height(mast lowered) mm | 2200 | |

H2 Overall height(mast extend) mm | 4260 | |

H3 Overall height to overhead guard mm | 2200mm | |

B3 Fork width mm | 125mm | |

H4 Fork thickness mm | 45mm | |

A3 Fork length mm | 1070(1220)mm | |

A1 Fork overhang mm | 494mm | |

A2 Wheel base mm | 1700mm | |

Tread | Front tread mm | 1000mm |

Rear tread mm | 980mm | |

Tyre | Front tyre | 28×9-15mm |

Rear tyre | 18×7-8mm | |

Total weight kg | 4900 | |

Motor | Traction motor | XQ-10-1C |

Lifting motor | XQD-13-3S | |

Battery | Battery type | 40-DA-500 |

Battery voltage/Capacity V/Ah | 80/500 | |

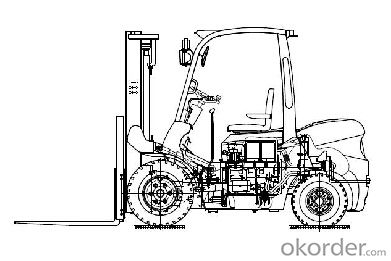

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q:What are the procedures for buying a forklift?

- legal representative (or head) id card (such as entrust to handle, needs to submit a power of attorney at the same time the original and one copy each of the client id photocopy; id photocopy should I signature); The registration form of the special equipment (two copies of the original);

- Q:How can the forklift truck change the antifreeze fluid and find no drainage

- Reload the water pipe and add new antifreeze fluid Note: the drain nozzle is normally on the water tank with the water pipe, the position is difficult to release water

- Q:The basics of driving a forklift

- Correct steering wheel. Forklift truck operation site is small, small turning radius, steering sensitivity, therefore, more modern forklift truck adopts hydraulic steering method, and on the steering wheel to install a 360 degree rotation of the ball back and forth or the handle. When driving, the handle should be held in the left hand. Many beginners are not used to this way of driving, steering wheel, when time killed some also like the direction of a place, it will cause steering mechanism of wear and tear.

- Q:What should 80V force forklift voltage current be?

- Normal internal combustion forklift truck Generally use diesel, gasoline, liquefied petroleum gas or natural gas engine as power, load capacity of 1.2 ~ 8.0 tons, homework channel width is generally 3.5 ~ 3.5 meters, emissions and noise into consideration, usually used in outdoor, workshops or other places with special requirements for emissions and noise did not. Due to the convenience of fuel replenishment, long time continuous work can be achieved, and can be suitable for work in bad environment (such as rain).

- Q:The photo of the forklift card is a few inches. Is it colorful?

- I am engaged in this aspect, two inches, normal document photo, blue bottom

- Q:Is a forklift and a hug a car

- To lift a car is to add a harness to the forklift truck Assemble in front of the door For holding the paper roll The handle and operation mode of the holding clamp are the same as the operation of the fork in the ordinary forklift truck

- Q:What about the steering wheel of an electric forklift without stepping on the accelerator?

- This is normal because there is a switch on the accelerator to open the low speed hydraulic pump.

- Q:Learn the forklift truck, will you be tired in the future?

- Compared to talking about the forklift in the production line, but any job that lasts longer is tiring.

- Q:What are some of the common failures of forklifts?

- Forklifts cannot be started with the following conditions: 1, the battery without electricity Failure of starter The key switch is bad 4, the oil pump does not supply oil 5, there was no oil tank 6, no oil 7, the crankshaft lock The engine was completely scrapped

- Q:The forklift test has those projects

- The forklift test is divided into three subjects, which are mainly for the pre-operation inspection of forklift truck, forklift truck and forklift truck. Forklift test subject 1: forklift operation check Before and after the forklift operation, the appearance should be inspected, and the fuel, lubricating oil and cooling water should be added. Check for starting, running and braking safety. Check to see if the lights and speakers are fully available. The forklift should check the pressure and the temperature is normal. The forklift should also check the leak and replace the sealing parts in time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

3 Tons Battery Powered Forklift CPD 30C

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords