280W Poly solar Panel Mediuml Solar Panel Hot Selling Solar Panel CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 300000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polycrystalline Solar Modules

CNBM offers a range of small, medium and large polycrystalline solar modules, designed for a range of requirements.

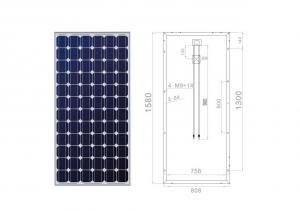

Specifications:

+/-3% |

Polycrystalline silicon solar cells (156 x 156mm) |

60 (10 x 6) |

1650 x 990 x 40 |

25.5 |

Limits:

Operating Temperature | -40~+85? |

Storage Temperature | -40~+85? |

Maximum System Voltage | 1000 VDC max. |

Hail Impact | Diameter of 28mm with impact speed |

Temperature and Coefficients:

NOCT | 48C+/-2? |

Voltage temperature coefficient (%/K) | -0.35 |

Current temperature coefficient (%/K) | 0.05 |

Power temperature coefficient (%/K) | -0.45 |

Characteristics:

Model: | SGM-200P | SGM-210P | SGM-220P |

Max-power voltage Vmp (V) | 29.2 | 29.4 | 29.41 |

Max-power current Imp (A) | 6.85 | 7.14 | 7.48 |

Open-circuit voltage Voc (V) | 36.5 | 36.69 | 36.9 |

Short-Circuit Current Isc (A) | 7.28 | 7.6 | 7.93 |

Max-power Pm(W) | 200 | 210 | 220 |

Model: | SGM-230P |

Max-power voltage Vmp (V) | 29.8 |

Max-power current Imp (A) | 7.72 |

Open-circuit voltage Voc (V) | 37.31 |

Short-Circuit Current Isc (A) | 8.19 |

Max-power Pm(W) | 230 |

STC: Irradiance 1000W/m2, module temperature 25?, AM-=1.5

Poly Crystalline Solar Panels Specifications Range

Maximum Power (Pm) | Dimension | Weight | Operating Voltage (Vmp) | Operating Current (Imp) | Open Circuit Voltage (Voc) | Short Circuit Current (Isc) |

0.45W | 140x80x10mm | 0.08kg | 3.3V | 150mA | 4.6V | 160mA |

1.0W | 162x140x10mm | 0.16kg | 7.5V | 150mA | 10.3V | 160mA |

4.5W | 269x251x23mm | 0.8kg | 16.5V | 0.27A | 20.5V | 0.3A |

10W | 420.1×268.9×22.6mm | 1.92kg | 17.5V | 0.58A | 20.5V | 0.6A |

20W | 425x502x50mm | 3.0kg | 16.8V | 1.19A | 21.0V | 1.29A |

30W | 593x502x22.6mm | 3.9kg | 16.8V | 1.78A | 21.0V | 1.94A |

40W | 655x537x50mm | 5.75kg | 17.3V | 2.31A | 22.1V | 2.54A |

50W | 839x537x50mm | 6.0kg | 17.5V | 2.9A | 21.8V | 3.17A |

65W | 1111x502x50mm | 7.2kg | 17.6V | 3.69A | 22.1V | 3.99A |

80W | 1204x537x50mm | 7.7kg | 17.6V | 4.55A | 22.1V | 4.8A |

- Q:The first panel is located in New England, the second is placed in the Sahara desert, the third is on the Earth side of the moon, and the last is on the far side of the moon. Which panel would absorb the most sunlight over a year's time and why ? All the panels are place in optimal places where they would get the most light available.

- They all face the sun about 50% of the time on average over the year. Best: far side of the moon, 2nd near side of the moon; because in the first case the panel is a moon-orbit-diameter closer to the sun at time of exposure. I think the Sahara and New England come next for reasons already given, in addition to the significant amount of energy absorbed by the atmosphere even to reach the Sahara.

- Q:i need how a solar panel works, if possible make as easy to understand as possible like because of this , this happens and if you could please put a web source you got it from

- Sunlight (photons) hit a piece of silicon and knock electrons out of it. That causes a flow of electrons, which is electrical current. simple enough? a better explanation from wikipedia: A solar cell is a device that converts the energy of sunlight directly into electricity by the photovoltaic effect. Sometimes the term solar cell is reserved for devices intended specifically to capture energy from sunlight such as solar panels and solar cells, while the term photovoltaic cell is used when the light source is unspecified.

- Q:I've been looking into solar panels. They are fairly expensive ($35k or so). My state has some rebates and grants available. Is anyone aware of any federal grants and rebates other than the federal tax credit? We are subject to AMT tax and can't take the credit. (Which is ridiculous, is the federal government committed to conservation or aren't they??????)

- Check out what someone did in Oakley, California - Contra Costa Times 22 June 2007 Going Solar Can Pay Off On The Long Run PGE Electric Power Monthly Bill Before Solar = $,200. Home: 2,900 sq. ft. Installation Cost for 6.7 Kilowatt 36-solar cells $46,000 (minus $7,60 State rebate). New Resources Bank, a “green” bank in San Francisco, lend them a, no-fee, no-points, second mortgage at $200 a month less than their previous monthly payments because of their plan to install solar panels. PGE Current Electricity Monthly Bill After Solar = $7.63 after deductions for any excess power produced by solar cell which PGE.is legally required to buy. PGE has not build any new electric power plants in California for years and their profits do not depend on sales volume, Sen. Feinstein introduced a bill to make this a National Law. Poweful interests are against this, perhaps they are foreign companies that hate Americans? Surely, they are not bona fide, red blooded Americans that love all the people in the U. S. of America, you think?

- Q:Can solar panels be used in areas with frequent lightning storms?

- Yes, solar panels can be used in areas with frequent lightning storms. While lightning poses a potential risk, modern solar panels are designed with safety features to mitigate the impact of lightning strikes. These features include grounding systems, surge protectors, and lightning arrestors. Additionally, solar panels are built to withstand extreme weather conditions, including lightning storms, ensuring their durability and functionality in such areas.

- Q:Can solar panels be used for powering an electric fence?

- Yes, solar panels can be used to power an electric fence. Solar panels can generate the necessary electricity to charge the fence's battery, ensuring a constant power supply for the electric fence system.

- Q:I'm a carpenter, and can do electric work. I want to make some money installing Solar Panels. what's the best source?

- Wow. This is a big question. First, are you in the United States? If so, then I would look at a couple of web sites. First, I would look at joining ASES - the American Solar Energy Society. (Actually, I'd do this whether or not you were in the US) Their magazine will have ads and directorys and so forth for panel manufacturers, inverter manufacturers, rack vendors, metering companies, etc. At the very least, their web site will give you numerous links to popular panel manufacturers. Right now, it can be difficult to get panels in the US. My buying agent can't promise us a significant number of panels until at least late this coming fall. And prices are going up due to a silicon shortage at the moment. Still, you could probably get your hands on small quantities. You just might not be able to choose exactly which manufacturer you want. Also, I'd look into getting NABCEP certification. This is the North American Board of Certified Energy Practitioners. They provide a referral service for people looking for solar installers, and they may have a net work of members that could help get you started. Good luck!

- Q:How much space is needed to install solar panels?

- The amount of space needed to install solar panels varies depending on the size and quantity of panels being installed. On average, a single solar panel requires about 15-20 square feet of space. However, it's important to consider factors like panel orientation, shading, and energy requirements to determine the exact space needed for an installation.

- Q:Can solar panels be installed on a university or college campus?

- Yes, solar panels can be installed on a university or college campus. In fact, many educational institutions have already embraced renewable energy and have successfully installed solar panels on their campuses. These panels can help offset the electricity consumption of the campus, reduce carbon emissions, and provide a hands-on learning opportunity for students interested in sustainability and renewable energy.

- Q:Would like to know if the DIY Solar panel systems can be as efficient as a commercial grade panel.

- They can be if you are well educated and skilled in their assembly and working functionality, provided you obtain the same high quality grade cells and do proper assembly. Chances are good however that your first several may be just a little below par until you really get the hang of it and become well practiced just as the professionals are. Does take a considerable amount of grunt work however so figure if this is best use of your time or if you'd do better to earn at your regular work and pay a professional to do that which they do best.

- Q:How much energy can a solar panel produce?

- The amount of energy a solar panel can produce depends on several factors, including its size, efficiency, and location. On average, a residential solar panel system can generate anywhere from 10 to 20 kilowatt-hours (kWh) of electricity per square meter per day. However, this can vary significantly based on sunlight availability, panel orientation, and weather conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

280W Poly solar Panel Mediuml Solar Panel Hot Selling Solar Panel CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 300000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords