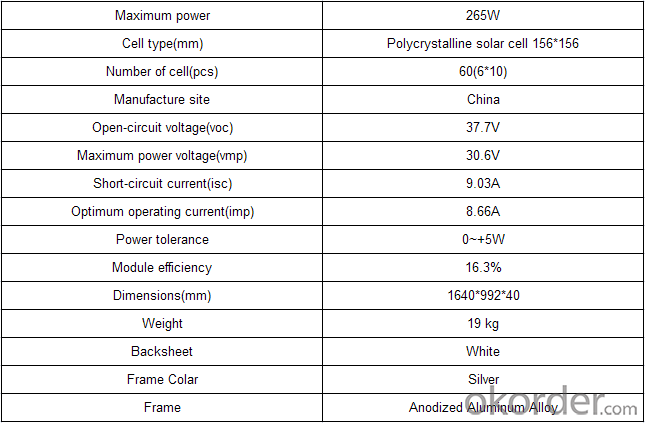

265W Solar Panel Silicon Polycrystalline

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INTRODUCTION

This installation Manual contains essential information for the electrical and mechanical installation that your must know before installing CUSTOMER PV modules. This also contains safety information you need to be familiar with .All the information described in this manual are the intellectual property of CNBM and based on the technologies and experiences that have been acquired and accumulated in the long history of CUSTOMER. This document does not constitute a warranty, expressed or implied.

CUSTOMER does not assume responsibility and expressly disclaims liability for loss, damage, or expense arising out of in anyway connected with installation, operation, use or maintenance of the PV modules. No responsibility is assumed by CUSTOMER for any infringement of patents or other rights of third parties that may result from use of PV module.

CUSTOMER reserves the right to make changes to the product, specifications or installation manual without prior notice.

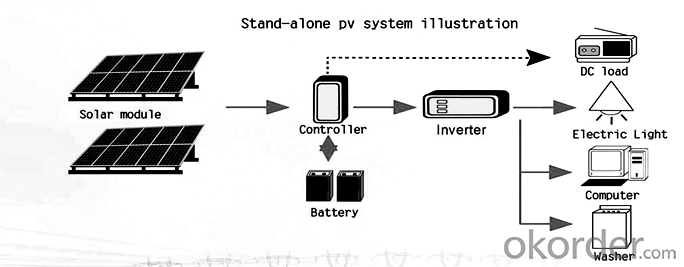

WORK PRINCIPLE

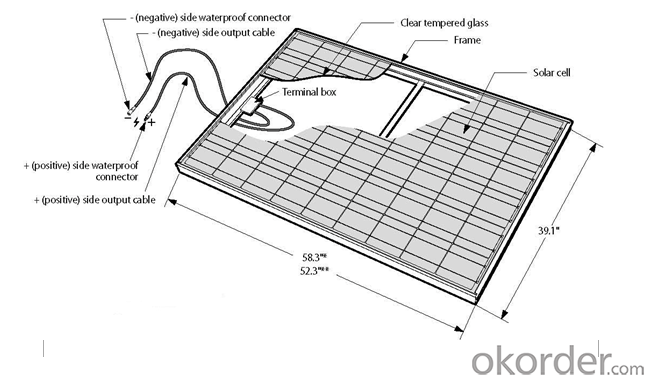

COMPONENTS

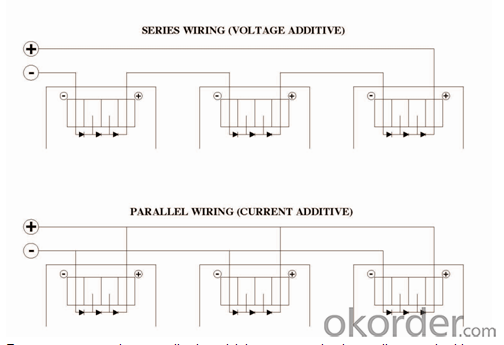

WIRING

To ensure proper system operation to maintain your warranty, observe the correct cable connection polarity(Figures 1&2) when connecting the modules to a battery or to other modules. If not connected correctly, the bypass diode could be destroyed.

PV modules can be wired in series to increase voltage. Connect wires from the positive terminal of one module to the negative of the next module. Figure shows modules connected in series .

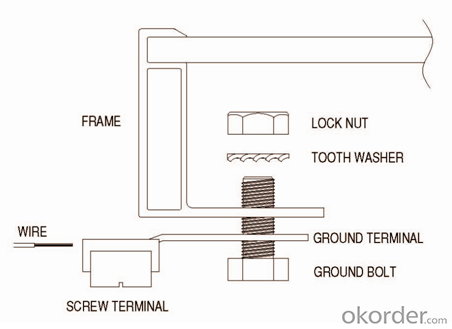

GROUDING

All PV models must be grounded by electrical connection of the module frames to ground. Please be careful in arranging the system ground so that the removal of one module from the circuit will not interrupt the grounding of any other modules.

The modules should be grounded to the same electrical point as described below.

Each PV module has a hole on the side frame of either a bolt, nut and washer grounding the module to the frame, a ground lug fastened by bolt or screw, or appropriate screw(hardware not provided).An example of acceptable ground connection using a bolt, nut and washer retaining a ground lug is shown in figure 3,in a connection of this type, the hardware(such as a toothed locked washer/star washer) must score the frame surface to make positive electrical contact with the frame. The ground wire must be considered within the requirement of local and regulation at the site of installation.

MOUNTING

Please make sure that all the information described in the installation manual is still valid and proper for your installation. The mounting method has been verified by CNBM and NOT CERTIFIED by a third party organization.

The approved way to mount CNBM PV modules to a support structure is using the bolt holes provided as described in the Specifications. Although CNBM does not specify or warrant frame clips or clamps, using frame clips (not provided ) or clamps module (not provided ) is also possible when they are designed for PV modules and with minimum dimensions on the sides of the module in accordance with the instructions and drawings provided. If using frame clips or clamps, the modules should be fixed rigidly and there shall be no damage to the modules by deforming mounting structure against design load. CNBM does not specify or warrant frame clips. The CNBM module warranty may be void if customer-selected trame clips which are improper or inadequate with respect to the module properties(including strength or material)or installation. Note that if metal clips are used, there must be a path to ground from the clips.(for instance, using star washers in the clip hardware set). Please review the descriptions and drawings carefully; not mounting the modules according to one of these methods may void your warranty. These mounting methods are designed to allow module loading of 2400pa.

- Q:Can solar panels be integrated into building materials?

- Yes, solar panels can be integrated into building materials. This innovative approach, known as building-integrated photovoltaics (BIPV), allows solar panels to be seamlessly incorporated into various architectural elements such as roofs, facades, windows, and even entire building structures. BIPV offers a dual function by serving as both a source of renewable energy and a structural component, enabling buildings to generate sustainable electricity while maintaining aesthetic appeal.

- Q:So idk how to connect a solar panel to a battery ...is it like a series connection from the solar panel to the battery, or a parallel connection from solar cell to battery? (to charge) please and thank you

- I agree, you should get a charge controller and install appropriate fuses.

- Q:Do solar panels require a battery backup system?

- No, solar panels do not necessarily require a battery backup system. Solar panels generate electricity from sunlight, but without a battery backup, the excess energy produced during the day is typically fed back into the grid. However, a battery backup system can be useful in areas with frequent power outages or for those who want to store and use the solar energy generated during the night or when the grid is down.

- Q:Can solar panels be used for powering agricultural irrigation systems?

- Yes, solar panels can be used to power agricultural irrigation systems. Solar energy can be converted into electricity through photovoltaic cells, which can then be used to power irrigation pumps and other equipment needed for agricultural irrigation. This offers a sustainable and cost-effective solution for powering irrigation systems, especially in remote agricultural areas where access to electricity may be limited.

- Q:I heard that solar energy has a lot of advantages but are there any drawbacks in using the solar panels?

- I guess the main thing is to look out for the warranty like where the warranty is claimed and the process of claim, how efficient the inverter of the system is and also make sure you are getting value for your money.

- Q:Are there different types of solar panels?

- Yes, there are different types of solar panels. The most common types are monocrystalline, polycrystalline, and thin-film solar panels. Each type has its own unique manufacturing process and efficiency levels, making them suitable for different applications and budgets.

- Q:Can solar panels work in the shade?

- The okorder / All solar panels sold by Energy Matters have bypass diodes, which send output from the remaining cells around that dead cell. However, you have lost the output of that cell, so the total panel voltage will drop by about 0.48 volts per cell. Most panels are in the 6 to 8 volt range, and most batteries need at least 3.5 volts to charge completely. So, if 2 or more cells are shaded, the output voltage of the panel may drop too low to charge the battery.

- Q:Can solar panels be installed on mountain huts or lodges?

- Yes, solar panels can be installed on mountain huts or lodges. In fact, mountain huts and lodges are often ideal locations for solar panel installations due to their remote locations and ample access to sunlight. Solar panels can provide a sustainable and reliable source of electricity for lighting, heating, and powering various appliances in these mountainous areas.

- Q:Can solar panels be used in areas with high winds?

- Yes, solar panels can be used in areas with high winds. However, it is important to ensure that the solar panel installation is designed and built to withstand the specific wind conditions of that area. This may involve using appropriate mounting systems, securing the panels properly, and considering the orientation and tilt angles. Additionally, selecting high-quality materials and conducting regular maintenance can help ensure the longevity and performance of the solar panels in high wind areas.

- Q:In some countries where electric generation is low, they are not available easily.

- Believe it or not, solar panels are so expensive in this country because of government subsides. Without market competition, companies have no obligation to compete with each other on price. If our government would stop paying people to buy solar panels and giving solar panel companies tax breaks, companies would be forced to lower their price and raise their quality in order to get you to buy their product. This would be true of oil/gas, corn, soy beans and a number of other companies and products as well.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

265W Solar Panel Silicon Polycrystalline

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords