235W Poly solar Panel Medium Poly Solar Panel Newest Solar Panel CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 300000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

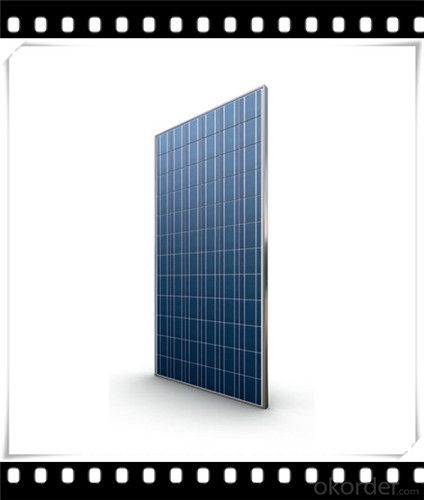

Polycrystalline Solar Modules

CNBM offers a range of small, medium and large polycrystalline solar modules, designed for a range of requirements.

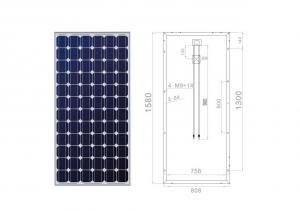

Specifications:

+/-3% |

Polycrystalline silicon solar cells (156 x 156mm) |

60 (10 x 6) |

1650 x 990 x 40 |

25.5 |

Limits:

Operating Temperature | -40~+85? |

Storage Temperature | -40~+85? |

Maximum System Voltage | 1000 VDC max. |

Hail Impact | Diameter of 28mm with impact speed |

Temperature and Coefficients:

NOCT | 48C+/-2? |

Voltage temperature coefficient (%/K) | -0.35 |

Current temperature coefficient (%/K) | 0.05 |

Power temperature coefficient (%/K) | -0.45 |

Characteristics:

Model: | SGM-200P | SGM-210P | SGM-220P |

Max-power voltage Vmp (V) | 29.2 | 29.4 | 29.41 |

Max-power current Imp (A) | 6.85 | 7.14 | 7.48 |

Open-circuit voltage Voc (V) | 36.5 | 36.69 | 36.9 |

Short-Circuit Current Isc (A) | 7.28 | 7.6 | 7.93 |

Max-power Pm(W) | 200 | 210 | 220 |

Model: | SGM-230P |

Max-power voltage Vmp (V) | 29.8 |

Max-power current Imp (A) | 7.72 |

Open-circuit voltage Voc (V) | 37.31 |

Short-Circuit Current Isc (A) | 8.19 |

Max-power Pm(W) | 230 |

STC: Irradiance 1000W/m2, module temperature 25?, AM-=1.5

Poly Crystalline Solar Panels Specifications Range

Maximum Power (Pm) | Dimension | Weight | Operating Voltage (Vmp) | Operating Current (Imp) | Open Circuit Voltage (Voc) | Short Circuit Current (Isc) |

0.45W | 140x80x10mm | 0.08kg | 3.3V | 150mA | 4.6V | 160mA |

1.0W | 162x140x10mm | 0.16kg | 7.5V | 150mA | 10.3V | 160mA |

4.5W | 269x251x23mm | 0.8kg | 16.5V | 0.27A | 20.5V | 0.3A |

10W | 420.1×268.9×22.6mm | 1.92kg | 17.5V | 0.58A | 20.5V | 0.6A |

20W | 425x502x50mm | 3.0kg | 16.8V | 1.19A | 21.0V | 1.29A |

30W | 593x502x22.6mm | 3.9kg | 16.8V | 1.78A | 21.0V | 1.94A |

40W | 655x537x50mm | 5.75kg | 17.3V | 2.31A | 22.1V | 2.54A |

50W | 839x537x50mm | 6.0kg | 17.5V | 2.9A | 21.8V | 3.17A |

65W | 1111x502x50mm | 7.2kg | 17.6V | 3.69A | 22.1V | 3.99A |

80W | 1204x537x50mm | 7.7kg | 17.6V | 4.55A | 22.1V | 4.8A |

- Q:Monocrystalline panels are sooo expensive! Thanks for reading.

- Since you are asking for a rather technical answer you should be aware that solar panels come in several varieties. Two broad categories are photovoltaic panels which have achieved marketable efficiencies of around 24% and solar thermal panels which are routinely achieving efficiencies of between 60 to 80% while they are also much cheaper than photovoltaic panels. So the short answer is solar thermal panels. But what can you do with solar thermal energy. The answer is just about everything you can do with light energy. Sometimes additional equipment makes the efficiency drop to near that of photovoltaic panels. The trick is to keep the devices as simple and as efficient as possible. Solar thermal can of course be used to heat our homes. But it can also be used directly for air conditioning. The type of air conditioner uses a slightly different principal but it is one of the oldest that was once used in ice houses before refrigerators. It is known as an absorption system. At some point you may want to make electricity from the sun's heat. The most efficient commercial systems are not photovoltaic but solar thermal. There are several commercial systems where increased scale improves efficiency. The most efficient is a solar parabolic dish system combined with a stirling engine. At around 30% efficiency it beats photovoltaic and other thermal systems. At this level of commercial development, the various systems are more often described as solar collectors rather than panels.

- Q:I recently bought a house with very old solar panels (about 25 years old) that don't appear to work properly. They are supposed to heat the hot water heater but they don't always work, and recently have staretd leaking. So, I have had them turned off and now we're just using electricity to heat the hot water. My question is, is there any tax credit money (stimulus or otherwise) available for people to (a) repair old solar panels or (b) replace them with new ones? How does the credit work?

- If you buy NEW solar panels, there is a credit. see the 040 icon at www.okorder

- Q:Can solar panels increase the value of my property?

- Yes, solar panels can increase the value of your property. Studies have shown that properties equipped with solar panels have higher resale values compared to those without. Solar panels offer energy savings, environmental benefits, and potential tax incentives, making them an attractive feature for potential buyers. Additionally, as renewable energy becomes increasingly popular, properties with solar panels are likely to be in higher demand, further boosting their value.

- Q:Can solar panels be installed on a sloped roof?

- Yes, solar panels can be installed on a sloped roof. In fact, sloped roofs are a common choice for solar panel installations as they offer an optimal angle for capturing sunlight. However, it is important to consider the pitch and orientation of the roof to ensure maximum efficiency and proper installation.

- Q:Is it possible for a 2V rated panel to charge a bank of batteries equal to around 36V? I believe that the panels should equal or exceed the voltage of the batteries but, I'm not for certain.

- you'll have to use 3 panels connected in series or use a dc to dc up converter, the former is a better option

- Q:What is the environmental impact of solar panels?

- Solar panels have a positive environmental impact as they generate clean and renewable energy without emitting greenhouse gases. While their production and disposal have some environmental costs, their use reduces reliance on fossil fuels, decreases air pollution, and mitigates climate change.

- Q:Can solar panels be used for powering a telecommunications tower?

- Yes, solar panels can be used for powering a telecommunications tower. Solar panels convert sunlight into electricity, which can then be used to power various devices, including telecommunications equipment. This renewable energy option is sustainable and environmentally friendly, making it an increasingly popular choice for powering remote or off-grid telecom towers.

- Q:How many kilowatts? Would it be enough to power my electric heat?Does one panel cost about $2000.?

- The first thing to understand is that there is nothing complex about a solar panel. It is nothing more than a collection of solar or PV cells on a board that is fitted to the most appropriate part of your home, generally on the roof. There are guides out there that teach you how to build a solar panel and a windmill for just $50, and it’s very easy to make. Best of all, you can save 70% or more on your energy bill, adding up to thousands of dollars each year in savings. I reviewed both free guides and paid guides and have come up with our top to Build your own solar panels.

- Q:I live in the UK, I have no savings (so would have to take out a loan of about ?8000), I don't know how long I plan to stay in my house, I might want to move in a year or two to take advantage of a better job so I want to keep the option open of being able to sell my house without having to pay off the cost of having the panels fitted (which I probably won't get back on the increased value they add to my house).What are the main advantages of having solar panels?What are the pitfalls the ever so eager cold callers with quotas to fill don't tell you about?Basically is it worth having them?Thankyou.

- If you're talking about photovoltaic panels, for making electricity, they're very expensive. Around here I think it runs around 2 bucks a watt of capacity, just for the panels. Then they have to be installed of course, which means an electrician has to be paid, and you need an inverter also. You can also spring for a bank of deep cycle batteries if you want to be able to store the electricity from the panels to use at night or on cloudy days, but that adds another very large expense. Now if electricity is very, very expensive where you are, you could maybe pay this off in a few years, but I doubt you could pay off 8000 pounds worth of this stuff in only a couple years. If you're talking about solar for water or air heating, well, that's another deal. But those kind of setups cost a lot less to put in, I can't see anyone paying that much for it.

- Q:Can solar panels be installed on military bases or installations?

- Yes, solar panels can be installed on military bases or installations. In fact, many military bases around the world have already incorporated solar energy as a part of their sustainability initiatives. Installing solar panels on military bases not only helps reduce their reliance on traditional energy sources but also enhances their energy security and resilience.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

235W Poly solar Panel Medium Poly Solar Panel Newest Solar Panel CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 300000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords