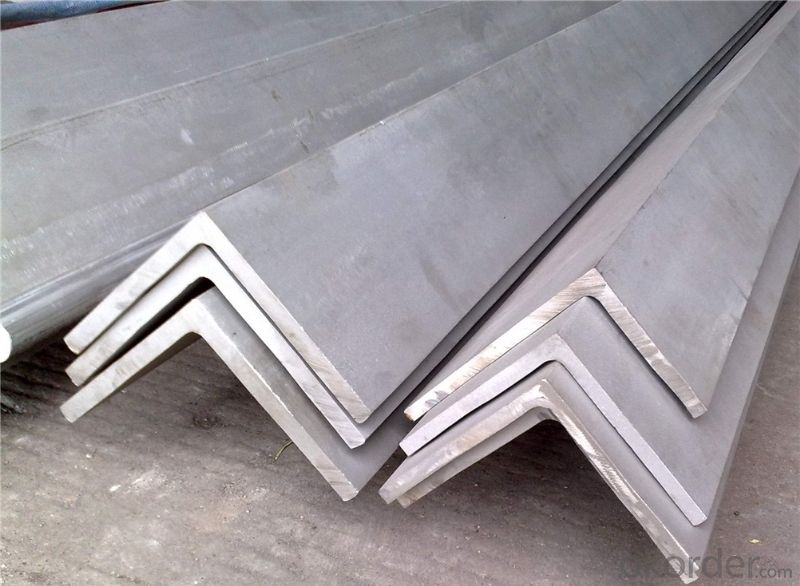

20mm*2.5mm hot sell Equal Angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry and so on

Name | Stainless Steel Angles | ||||||

Standard | ASTM A554, A312, A249, A269 and A270 | ||||||

Material Grade | 304,316,201,202, 316L,430 | ||||||

Length | 6m or as customers' request | ||||||

Tolerance | a) thickness: +/-0. 15mm | ||||||

b) Length:+/-4. 5mm - 0mm | |||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

Application | Decoration construction, upholstery, industry instruments | ||||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

Chemical Composition of Material |

Composition

Material | 201 | 202 | 304 | 316L | 430 | |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | ||

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ||

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | ||

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | ||

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | ||

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | ||

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | |||

Mo | 2.0-3.0 | ||||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | ||

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | |||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | |||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | |||

Hardness (HV) | <253 | <253 | <200 | <200 | |||

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q:What is the maximum allowable tensile stress for a steel angle?

- The maximum allowable tensile stress for a steel angle depends on various factors such as the specific grade of steel, the manufacturing process, and the intended application. Steel angles are commonly used in construction and structural applications, and their maximum allowable tensile stress is typically determined by industry standards and design codes. For example, in the United States, the American Institute of Steel Construction (AISC) provides design specifications for structural steel angles. According to AISC, the maximum allowable tensile stress for a steel angle is typically based on the yield strength of the steel material. The yield strength refers to the stress at which a material begins to deform permanently. It is usually specified in terms of pounds per square inch (psi) or megapascals (MPa). Steel angles are typically designed to operate within a certain percentage of their yield strength to ensure structural integrity and safety. In general, the maximum allowable tensile stress for a steel angle is often limited to a percentage of its yield strength, typically ranging from 50% to 70%. This means that the maximum tensile stress that can be applied to a steel angle is a fraction of its yield strength. It is crucial to consult the appropriate design standards and codes, such as those provided by AISC or other relevant organizations, to determine the specific maximum allowable tensile stress for a given steel angle in a particular application. These standards consider factors such as load conditions, safety factors, and environmental conditions to ensure the structural integrity and reliability of the steel angle.

- Q:What is the maximum slope for a steel angle?

- The maximum slope for a steel angle depends on various factors such as the size, shape, and thickness of the angle. However, in general, steel angles are designed to withstand vertical loads and provide stability in structural applications. Therefore, the maximum slope for a steel angle is typically limited to angles less than 45 degrees. Going beyond this angle may compromise the structural integrity of the angle and increase the risk of failure. It is important to consult engineering codes, standards, and specifications to determine the specific maximum slope for a particular steel angle in a given application.

- Q:Can steel angles be used as supports for suspended acoustical ceilings?

- Steel angles have the capacity to function as supports for suspended acoustical ceilings. They are frequently employed as a primary structural element in suspended ceiling systems, serving to establish stability and provide support for the acoustical ceiling tiles. Additionally, they aid in evenly distributing the weight across the ceiling grid. To ensure the secure installation and optimal sound absorption, the steel angles are typically placed at regular intervals along the ceiling's perimeter and connected to the main suspension system. The utilization of steel angles guarantees that the acoustical ceiling remains firmly in position while effectively enhancing the acoustic qualities of the area.

- Q:What are the different surface coating options for steel angles?

- There are several different surface coating options available for steel angles, depending on the specific requirements and desired properties. Some of the most common options include: 1. Galvanizing: This is a popular coating method where a layer of zinc is applied to the steel surface. Galvanizing provides excellent corrosion resistance, making it suitable for outdoor applications or environments with high moisture levels. 2. Powder coating: Powder coating involves electrostatically applying a dry powder to the steel surface, which is then cured through heat to form a durable and smooth coating. It offers a wide variety of colors and finishes while providing good corrosion resistance and aesthetics. 3. Paint: Painting is another common coating method that involves applying a layer of paint to the steel surface. Paint offers a range of colors and finishes, and it can provide corrosion protection when combined with a suitable primer. 4. Epoxy coating: Epoxy coatings are known for their exceptional corrosion resistance and chemical resistance. They are often used in environments with exposure to chemicals or harsh conditions. Epoxy coatings can be applied as a liquid or powder and are cured to form a hard and protective layer. 5. Phosphate coating: Phosphate coatings are typically used as a pre-treatment before painting or powder coating. They provide improved adhesion and corrosion resistance, acting as a base layer for subsequent coatings. 6. Anodizing: Anodizing is typically used for aluminum, but it can also be applied to steel. It involves creating a layer of oxide on the surface, which enhances corrosion resistance and provides a decorative finish. It is important to consider factors such as the intended application, environmental conditions, aesthetic preferences, and budget when selecting the appropriate surface coating option for steel angles. Consulting with coating specialists or experts can help in determining the best coating option for specific requirements.

- Q:What is the difference between hot-rolled and cold-formed steel angles?

- Hot-rolled steel angles and cold-formed steel angles find use in various construction and industrial applications, but they differ in how they are made and the characteristics they possess. To produce hot-rolled steel angles, a steel billet or slab is heated above its recrystallization temperature and then passed through rollers to shape it as desired. This process allows for the creation of bends, curves, and other intricate angles. Hot rolling also leads to a rougher surface finish and slightly rounded edges, which can be advantageous in certain applications. Furthermore, hot-rolled steel angles are available in a wider range of sizes and thicknesses. On the other hand, cold-formed steel angles are formed by bending a flat strip of steel at room temperature using dies and rolls. This process does not involve heating the steel, preserving its existing physical properties. Consequently, cold-formed steel angles have a smoother surface finish and sharper, more defined edges compared to hot-rolled angles. The cold-forming process also enables tighter tolerances and more precise dimensions. Regarding mechanical properties, hot-rolled steel angles generally exhibit higher tensile strength and yield strength than cold-formed angles. This can be attributed to the heat treatment involved in hot rolling, which refines the grain structure and enhances the overall strength of the steel. Cold-formed steel angles, while typically less strong, are often preferred when weight reduction is a priority, as they are generally lighter than their hot-rolled counterparts. In conclusion, the main distinctions between hot-rolled and cold-formed steel angles lie in their manufacturing processes, resulting surface finishes, dimensional precision, and mechanical properties. The choice between the two depends on the specific requirements and limitations of the given project.

- Q:Can steel angles be easily modified or customized on-site?

- Steel angles have the capability to be effortlessly modified or customized on-site. One can cut, drill, weld, and bend steel angles to meet specific requirements. This adaptability permits convenient customization and adjustment of steel angles to fulfill diverse construction or fabrication needs. Moreover, on-site modifications are frequently essential to guarantee accurate fitting and alignment during installation. By utilizing the appropriate tools and expertise, steel angles can be modified and customized on-site with minimal difficulty.

- Q:How can steel angles be protected against corrosion?

- Steel angles can be protected against corrosion through various methods such as applying protective coatings like paint or galvanization, using corrosion inhibitors, implementing cathodic protection systems, or selecting stainless steel angles which are inherently resistant to corrosion.

- Q:What are the design considerations for using steel angles in architectural applications?

- Some design considerations for using steel angles in architectural applications include structural stability, load-bearing capacity, aesthetic appeal, corrosion resistance, and ease of installation. Steel angles are commonly used to provide support, reinforcement, and stability to various architectural elements such as beams, columns, and frames. The selection of the appropriate size, thickness, and grade of steel angle is crucial to ensure the structural integrity and safety of the building. Additionally, architects may consider the visual impact of steel angles, as they can be exposed or concealed depending on the design intent. The corrosion resistance properties of the steel angles should also be taken into account, especially in applications where exposure to moisture or harsh environments is expected. Lastly, the ease of installation and compatibility with other building materials should be considered to streamline the construction process.

- Q:Are steel angles resistant to vibrations?

- Steel angles are known for their strength and durability, but their resistance to vibrations can vary depending on various factors such as the thickness and quality of the steel, the design of the angle, and the specific application in which it is used. In general, steel angles have good inherent stiffness and can dampen vibrations to some extent. However, if the vibrations are severe or the steel angle is not properly designed or installed, it can be susceptible to fatigue failure or excessive movement. To enhance the resistance to vibrations, additional measures such as using thicker steel angles, designing proper bracing or support structures, or incorporating vibration damping materials can be employed. Therefore, it is important to consider the specific requirements and conditions of the application when determining the suitability of steel angles for resisting vibrations.

- Q:Are there any environmental concerns associated with steel angles?

- Yes, there are environmental concerns associated with steel angles. The production of steel angles involves the extraction of iron ore, which can have significant impacts on ecosystems, including habitat destruction and water pollution. Additionally, the manufacturing process of steel angles requires high energy consumption, contributing to greenhouse gas emissions and climate change. To mitigate these concerns, sustainable practices such as using recycled steel and improving energy efficiency in production can be implemented.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

20mm*2.5mm hot sell Equal Angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords