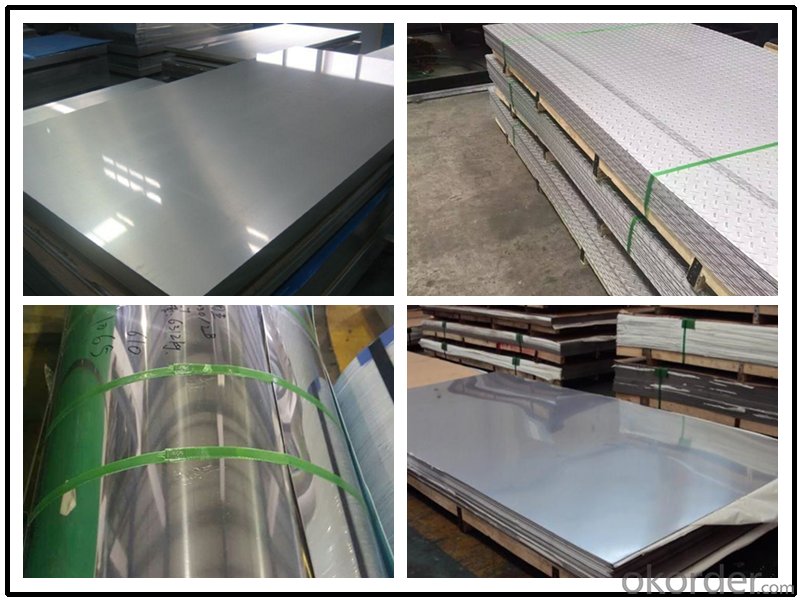

201 304 Stainless Steel Sheets TISCO LISCO ZPSS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

304 316 cold rolled stainless steel sheet

Standard:JIS,AISI,ASTM,GB,DIN,EN

Material:201,202,316,304,304L,316,316L,321,430,etc.

Thickness:0.5mm~2.0mm

Width: 1000mm~1250mm

Length:1000mm-6000mm or as your requirement

Finish:2B, BA, Hair Line, No.1,No.4, Mirror ,color,etching

Technique:cold rolled

Packaging & Shipping

Trade terms:

Packing: Standard export seaworthy packing with waterproof paper,metal belt pack sheet,then put them in wooden pallet(or put them in wooden case),then put them in container or as customer's requirement.

MOQ: 5 metric tons

Shipping Term: FOB GUANGDONG or CNF import port

Delivery Time: 15 to 35 days after the receipt of the deposit

Payment Term: T/T 30% deposit, Balance against the copy of B/L; or L/C at sight

201 304 cold rolled stainless steel sheets

Application

- Q:What is the magnetic permeability of stainless steel sheets?

- The magnetic permeability of stainless steel sheets can vary depending on the specific alloy and processing conditions. Generally, stainless steel is considered to have a low magnetic permeability, making it a poor conductor of magnetic fields. However, some types of stainless steel, such as ferritic stainless steel, have a higher magnetic permeability compared to other grades like austenitic stainless steel. It is important to note that the magnetic permeability of stainless steel can also be affected by factors such as temperature and the presence of external magnetic fields. Therefore, it is best to consult specific technical data or perform magnetic permeability testing for accurate and detailed information about the magnetic properties of stainless steel sheets.

- Q:What are the different types of stainless steel sheet alloys available?

- There are several different types of stainless steel sheet alloys available, each offering unique properties and characteristics. Some of the most common stainless steel sheet alloys include: 1. Austenitic Stainless Steel: This type of stainless steel is the most widely used and versatile. It is non-magnetic and contains high levels of chromium and nickel, offering excellent corrosion resistance and good formability. Austenitic stainless steel alloys include 304 and 316 grades. 2. Ferritic Stainless Steel: Ferritic stainless steel is magnetic and contains high levels of chromium. It has good corrosion resistance and is typically less expensive than austenitic stainless steel. Common ferritic stainless steel alloys include 430 and 446 grades. 3. Martensitic Stainless Steel: Martensitic stainless steel is magnetic and contains high levels of carbon and chromium. It is known for its hardness and strength, making it suitable for applications requiring high wear resistance. Martensitic stainless steel alloys include 410 and 420 grades. 4. Duplex Stainless Steel: Duplex stainless steel is a combination of austenitic and ferritic stainless steels, offering a balance of both their properties. It has increased strength and corrosion resistance compared to austenitic stainless steel. Common duplex stainless steel alloys include 2205 and 2507 grades. 5. Precipitation Hardening Stainless Steel: Precipitation hardening stainless steel alloys are heat treatable and can achieve high strength levels. They contain elements such as copper, aluminum, or titanium, which form precipitates during heat treatment, resulting in increased strength. Common precipitation hardening stainless steel alloys include 17-4PH and 15-5PH grades. It is important to consider the specific requirements of your application when selecting a stainless steel sheet alloy, as each alloy has its own strengths and limitations.

- Q:Are stainless steel sheets resistant to impact?

- Yes, stainless steel sheets are generally resistant to impact due to their high strength and durability. However, their level of impact resistance may vary depending on the specific grade and thickness of the stainless steel sheet.

- Q:Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q:Are stainless steel sheets scratch resistant?

- Yes, stainless steel sheets are generally scratch resistant. Stainless steel is known for its durability and resistance to scratching, making it a popular choice for various applications. However, it is important to note that while stainless steel is resistant to most scratches, it is not completely scratch-proof. Deep or abrasive scratches can still occur, especially if the surface is exposed to harsh or abrasive materials. Regular maintenance and care, such as avoiding the use of abrasive cleaners or scrubbing pads, can help minimize the risk of scratches and maintain the appearance of stainless steel sheets.

- Q:What are the different types of stainless steel sheet patterns?

- There are several different types of stainless steel sheet patterns, including plain, diamond, honeycomb, chequered, and linen. These patterns offer various aesthetic options for different applications and design preferences.

- Q:Are stainless steel sheets suitable for high-traffic areas?

- Indeed, high-traffic areas can benefit from the use of stainless steel sheets. Renowned for their durability, strength, and resistance to corrosion, stainless steel proves to be an outstanding option for spaces frequented by many individuals. It possesses the ability to endure continuous usage and mistreatment, encompassing scratches, dents, and impacts, all while maintaining its structural integrity. Moreover, stainless steel sheets present themselves as effortless to clean and maintain, rendering them an optimal choice for regions necessitating frequent cleaning and disinfection. In summary, stainless steel sheets offer a dependable and enduring solution for high-traffic areas.

- Q:Can stainless steel sheets be used for stairs and railings?

- Stairs and railings can indeed utilize stainless steel sheets. This remarkably resilient and adaptable material frequently finds its place in architectural and interior design endeavors. With its corrosion resistance, stainless steel proves suitable for outdoor settings and environments with elevated humidity or chemical exposure. The malleability of stainless steel sheets allows for their fabrication into diverse forms and dimensions, rendering them perfect for crafting stairs and railings with an elegant and contemporary appearance. Furthermore, stainless steel boasts effortless cleanliness and maintenance, thus making it a pragmatic selection for high-traffic areas or public spaces.

- Q:How do I prevent warping on stainless steel sheets?

- To prevent warping on stainless steel sheets, there are several steps you can take: 1. Proper storage: Store stainless steel sheets in a dry, flat, and well-ventilated area. Avoid storing them in humid or damp conditions as moisture can cause the sheets to warp. 2. Handling with care: When moving or handling stainless steel sheets, use proper lifting techniques to minimize stress on the material. Avoid dropping or mishandling the sheets, as this can lead to warping. 3. Proper cutting and shaping: When cutting or shaping stainless steel sheets, use appropriate tools and techniques to ensure clean and precise cuts. Avoid using excessive force or incorrect cutting methods, as this can cause the sheets to warp. 4. Controlled heat application: During welding or other heat-related processes, it is crucial to control the heat application. Excessive heat or uneven heating can lead to warping. Use proper techniques, such as preheating the material or using heat sinks, to distribute heat evenly and minimize the risk of warping. 5. Avoid overloading: Do not overload stainless steel sheets with excessive weight or pressure. Ensure that the load is evenly distributed to prevent deformation and warping. 6. Cooling process: After any heat-related processes, allow the stainless steel sheets to cool down slowly and naturally. Avoid rapid cooling methods, such as quenching with water, as this can cause uneven contraction and result in warping. 7. Quality control: Ensure that the stainless steel sheets you purchase are of high quality and meet the required standards. Inferior quality materials may have inherent defects that can lead to warping. By following these preventive measures, you can minimize the risk of warping on stainless steel sheets and maintain their integrity and quality.

- Q:Are stainless steel sheets suitable for medical equipment?

- Yes, stainless steel sheets are suitable for medical equipment. Stainless steel is a popular choice for medical equipment due to its excellent corrosion resistance and durability. It is easy to clean and sterilize, making it suitable for use in healthcare settings where cleanliness and hygiene are crucial. Additionally, stainless steel has a high strength-to-weight ratio, allowing for the construction of lightweight yet sturdy medical equipment. It also has a low magnetic permeability, making it ideal for applications where electromagnetic interference needs to be minimized. Overall, stainless steel sheets are a reliable and practical choice for manufacturing medical equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

201 304 Stainless Steel Sheets TISCO LISCO ZPSS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords