All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

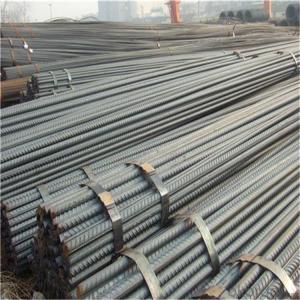

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the applications of special steel in the development of high-efficiency energy storage systems?

Special steel has various applications in the development of high-efficiency energy storage systems. It is commonly used in the construction of storage tanks and pressure vessels, ensuring strength and durability to contain compressed gases or liquids. Special steel is also utilized in the manufacturing of critical components like rotor shafts and bearings for energy storage systems such as flywheels. Its high strength and corrosion resistance properties make it ideal for withstanding the demanding conditions and prolonged use in energy storage applications. Moreover, special steel alloys are employed in the production of battery casings and current collectors in advanced energy storage technologies like lithium-ion batteries, enabling improved performance and safety. Overall, the applications of special steel contribute significantly to the efficient and reliable functioning of high-efficiency energy storage systems.

Can you explain the concept of hardening in special steel?

Hardening in special steel refers to a heat treatment process used to increase its strength and durability. It involves heating the steel to a specific temperature and then rapidly cooling it, typically by quenching in water or oil. This rapid cooling transforms the steel's microstructure, making it harder and less ductile. The hardened steel is then tempered to reduce brittleness and improve toughness. This process is commonly used in the manufacturing of tools, machinery components, and various industrial applications where high strength and wear resistance are required.

What role does titanium play in high-strength steel alloys and what applications does it have?

Titanium plays a crucial role in high-strength steel alloys as it helps enhance the strength and durability of the steel. By adding titanium, the steel becomes stronger, lighter, and more corrosion-resistant. This makes it ideal for applications in aerospace, automotive, and marine industries, where high-strength and lightweight materials are required. Additionally, titanium is also used in the production of medical implants, sports equipment, and even jewelry, thanks to its biocompatibility, strength, and aesthetic appeal.

What are the challenges in recycling high-alloy special steel?

One of the main challenges in recycling high-alloy special steel is the complexity of its composition. High-alloy special steels often contain a wide range of elements, including expensive and rare metals such as chromium, nickel, and molybdenum, which makes the separation and recovery of these valuable materials a difficult and costly process. Additionally, the presence of certain alloying elements can affect the properties and behavior of the steel during recycling, requiring specialized techniques and processes to ensure the quality and integrity of the recycled material. Moreover, the high melting points of some alloying elements may necessitate the use of high-energy processes for effective recycling, further adding to the challenges. Overall, the unique composition and properties of high-alloy special steel pose significant obstacles for its efficient and cost-effective recycling.

Wholesale Special Steel from supplier in Turkmenistan

Whether you are in the construction, oil and gas, manufacturing, or any other industry requiring Special Steel, we have the expertise and resources to meet your specific requirements. Our team of experienced professionals is dedicated to understanding your needs and providing personalized solutions that meet your project goals.

We offer a wide range of Special Steel products, including alloy steel, stainless steel, tool steel, and carbon steel, among others. Our products are sourced from reputable manufacturers worldwide, ensuring high quality and reliability. Whether you need bars, sheets, plates, pipes, or any other form of Special Steel, we can provide you with the right products at competitive prices.

In addition to our comprehensive product portfolio, we also offer technical support to ensure that you make informed decisions regarding the selection and application of Special Steel. Our team of technical experts is available to assist you with product specifications, material properties, and any other technical inquiries you may have. We believe that by providing excellent customer service and technical support, we can contribute to the success of your projects.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the financial strength and global network to offer comprehensive procurement services for Special Steel in Turkmenistan. We can handle all aspects of the procurement process, from product sourcing and negotiation to logistics and delivery. Our efficient procurement services ensure that you receive your Special Steel products on time and within budget.

With our years of market presence in Turkmenistan, we have developed strong relationships with local suppliers and manufacturers, enabling us to offer competitive pricing and timely delivery. We understand the unique challenges and requirements of doing business in Turkmenistan and are committed to providing tailored solutions that meet your specific needs.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships based on trust and mutual success. We are dedicated to providing high-quality Special Steel products, technical expertise, and comprehensive procurement services that add value to your projects in Turkmenistan.

Contact us today to discuss your Special Steel requirements and how we can assist you in achieving your project goals in Turkmenistan.

We offer a wide range of Special Steel products, including alloy steel, stainless steel, tool steel, and carbon steel, among others. Our products are sourced from reputable manufacturers worldwide, ensuring high quality and reliability. Whether you need bars, sheets, plates, pipes, or any other form of Special Steel, we can provide you with the right products at competitive prices.

In addition to our comprehensive product portfolio, we also offer technical support to ensure that you make informed decisions regarding the selection and application of Special Steel. Our team of technical experts is available to assist you with product specifications, material properties, and any other technical inquiries you may have. We believe that by providing excellent customer service and technical support, we can contribute to the success of your projects.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the financial strength and global network to offer comprehensive procurement services for Special Steel in Turkmenistan. We can handle all aspects of the procurement process, from product sourcing and negotiation to logistics and delivery. Our efficient procurement services ensure that you receive your Special Steel products on time and within budget.

With our years of market presence in Turkmenistan, we have developed strong relationships with local suppliers and manufacturers, enabling us to offer competitive pricing and timely delivery. We understand the unique challenges and requirements of doing business in Turkmenistan and are committed to providing tailored solutions that meet your specific needs.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships based on trust and mutual success. We are dedicated to providing high-quality Special Steel products, technical expertise, and comprehensive procurement services that add value to your projects in Turkmenistan.

Contact us today to discuss your Special Steel requirements and how we can assist you in achieving your project goals in Turkmenistan.