All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How are high-alumina and alumina-chrome refractories used in various industrial processes?

High-alumina and alumina-chrome refractories are widely used in various industrial processes due to their excellent resistance to high temperatures, corrosion, and thermal shock. These refractories are commonly employed in industries such as steelmaking, cement production, glass manufacturing, and petrochemical refining. In steelmaking, they are utilized in the lining of furnaces and ladles to withstand the extreme heat and chemical reactions involved in the process. In cement production, high-alumina refractories are used to line kilns, ensuring efficient heat transfer and protecting against wear and tear. Alumina-chrome refractories find application in glass manufacturing, where they can resist the harsh conditions of glass melting furnaces. Additionally, both types of refractories are essential in the petrochemical industry, providing excellent resistance to the corrosive effects of chemicals and maintaining structural integrity in reactors and furnaces. Overall, high-alumina and alumina-chrome refractories play a crucial role in various industrial processes by providing reliable and durable linings that can withstand the extreme conditions encountered.

What are the advantages of using silica nanoparticles as a raw material in refractory production?

Using silica nanoparticles as a raw material in refractory production offers several advantages. Firstly, silica nanoparticles have a high surface area to volume ratio, which enhances their reactivity and allows for better dispersion within the refractory matrix. This leads to improved mechanical properties and increased resistance to thermal shock.

Additionally, silica nanoparticles have a uniform particle size distribution, resulting in a more homogenous microstructure of the refractory material. This contributes to increased heat resistance, improved insulation properties, and enhanced chemical stability.

Furthermore, the small size of silica nanoparticles enables them to fill in gaps and voids in the refractory matrix, resulting in a denser and more compact structure. This leads to improved strength, reduced porosity, and increased resistance to erosion and corrosion.

Overall, the use of silica nanoparticles as a raw material in refractory production offers improved performance and durability, making it a favorable choice for various high-temperature applications.

What are the primary applications of refractory raw materials?

The primary applications of refractory raw materials are in industries that require high-temperature environments, such as steelmaking, ceramics, glass manufacturing, cement production, and petrochemical refining. These materials are used to create refractory products like bricks, castables, and monolithics that can withstand extreme heat, corrosion, and mechanical stress, making them essential for lining furnaces, kilns, reactors, and other thermal processing equipment.

What are the challenges in sourcing refractory raw materials?

The challenges in sourcing refractory raw materials include limited availability and access to high-quality deposits, fluctuating prices and market conditions, environmental regulations and sustainability concerns, and the need for continuous research and development to identify alternative materials. Additionally, geopolitical factors, transportation logistics, and supply chain management also pose challenges in ensuring a consistent and reliable supply of refractory raw materials.

Wholesale Raw Materials For Refractory from supplier in Tonga

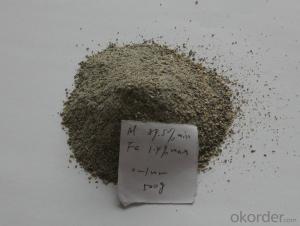

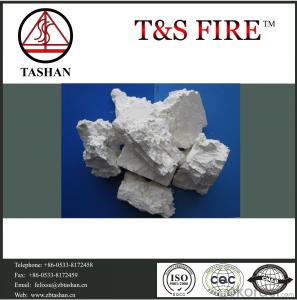

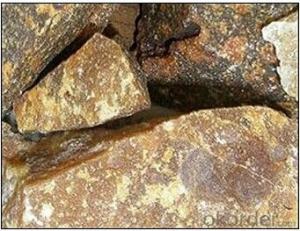

Whether you need raw materials for brickmaking, ceramics, or other refractory applications, we have you covered. Our product range includes various types of minerals, such as magnesite, bauxite, alumina, silica, and more. We source our materials from reliable suppliers worldwide, ensuring consistent quality and competitive prices.

Our dedicated sales team is ready to assist you with any inquiries or product recommendations. Whether you need assistance in selecting the right raw materials for your specific application or require technical support, we are here to help. Our experts have in-depth knowledge of the refractory industry, allowing us to provide tailored solutions for your projects.

We understand the importance of timely and efficient procurement processes. With our one-stop procurement services, you can save time and effort by consolidating your raw material needs with us. Our strong global network and supply chain management capabilities enable us to deliver products to your doorstep in a timely manner.

At CNBM, we value long-term partnerships with our customers. We strive to build trust and provide continuous support throughout your projects. Our years of experience in the Tongan market have given us valuable insights into local requirements and preferences. We can offer guidance on product selection, application techniques, and industry trends to help optimize your refractory solutions.

Choose us as your reliable supplier of raw materials for refractory in Tonga. Contact us today for sales inquiries, quotations, or technical support, and let us be your trusted partner in achieving success in your refractory projects.

Our dedicated sales team is ready to assist you with any inquiries or product recommendations. Whether you need assistance in selecting the right raw materials for your specific application or require technical support, we are here to help. Our experts have in-depth knowledge of the refractory industry, allowing us to provide tailored solutions for your projects.

We understand the importance of timely and efficient procurement processes. With our one-stop procurement services, you can save time and effort by consolidating your raw material needs with us. Our strong global network and supply chain management capabilities enable us to deliver products to your doorstep in a timely manner.

At CNBM, we value long-term partnerships with our customers. We strive to build trust and provide continuous support throughout your projects. Our years of experience in the Tongan market have given us valuable insights into local requirements and preferences. We can offer guidance on product selection, application techniques, and industry trends to help optimize your refractory solutions.

Choose us as your reliable supplier of raw materials for refractory in Tonga. Contact us today for sales inquiries, quotations, or technical support, and let us be your trusted partner in achieving success in your refractory projects.

Hot Search

- Monolithic Refractories in Tuvalu

- Ceramic Fiber Products in Mauritania

- Refractory Bricks in Bulgaria

- Raw Materials For Refractory in Oman

- Monolithic Refractories in Philippines

- Raw Materials For Refractory in Kenya

- Refractory Bricks in Armenia

- Raw Materials For Refractory in Angola

- Monolithic Refractories in Colombia

- Monolithic Refractories in Ireland