All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

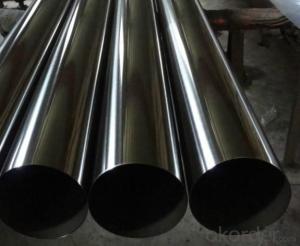

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

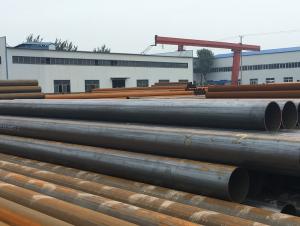

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can a welded steel pipe be used for drinking water supply?

Yes, a welded steel pipe can be used for drinking water supply. However, it is important to ensure that the steel used for the pipe is specifically designed and certified for potable water applications to prevent any contamination or health risks. Additionally, regular maintenance and inspection of the pipe is necessary to ensure its integrity and safety for drinking water supply.

Can welded steel pipe be used for wastewater treatment facilities?

Yes, welded steel pipe can be used for wastewater treatment facilities. Welded steel pipes are commonly used in the construction of wastewater treatment facilities due to their durability, strength, and resistance to corrosion. They are capable of withstanding the high pressure and harsh chemical environment often found in wastewater treatment processes. Additionally, welded steel pipes can be easily customized to meet the specific requirements of the facility, making them a suitable choice for wastewater treatment applications.

What are the factors that affect the flow velocity in welded steel pipes?

There are several factors that can affect the flow velocity in welded steel pipes. Some of the key factors include the diameter and length of the pipe, the roughness of the inner surface, the viscosity of the fluid flowing through the pipe, and the presence of any obstructions or bends in the pipe. Additionally, the pressure difference across the pipe, the temperature of the fluid, and the density of the fluid can also impact the flow velocity.

Can welded steel pipes be used for conveying chemicals?

Yes, welded steel pipes can be used for conveying chemicals. However, it is important to consider the specific chemical being conveyed and its compatibility with steel. Some chemicals may be corrosive to steel, so it is necessary to choose the appropriate grade of steel and coatings to prevent corrosion and ensure safe transportation of chemicals.

How is the yield strength of welded steel pipe measured?

The yield strength of welded steel pipe is typically measured using a tensile test, where a sample of the pipe is subjected to increasing amounts of tension until it deforms permanently. The point at which the material begins to deform is known as the yield point or yield strength.

Wholesale Welded Steel Pipe from supplier in Togo

Whether you are looking for standard or customized Welded Steel Pipe products, we have the capabilities to meet your specific requirements. Our team of experienced professionals is dedicated to delivering high-quality products on time and within budget.

In addition to our wide range of products, we also offer comprehensive sales, quotations, and technical support services. Our knowledgeable sales team is available to assist you throughout the entire procurement process, from initial inquiries to final delivery. We understand the importance of timely and accurate quotations, and we strive to provide competitive pricing for all our products.

Our technical support team is well-versed in the specifications and applications of Welded Steel Pipe products. Whether you need assistance with product selection, installation, or troubleshooting, our experts are here to help. We can provide detailed technical information, including specifications, performance data, and installation guidelines, to ensure the successful completion of your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to vast resources and expertise. This allows us to provide you with a seamless procurement experience, ensuring that you receive high-quality products that meet your specific needs. Our strong market presence in Togo enables us to offer valuable insights and expertise, helping you make informed decisions for your projects.

Whether you are in the construction, oil and gas, or infrastructure industry, we are confident that our Welded Steel Pipe products and services will meet your expectations. Contact us today to discuss your requirements and let us assist you in achieving your project goals in Togo.

In addition to our wide range of products, we also offer comprehensive sales, quotations, and technical support services. Our knowledgeable sales team is available to assist you throughout the entire procurement process, from initial inquiries to final delivery. We understand the importance of timely and accurate quotations, and we strive to provide competitive pricing for all our products.

Our technical support team is well-versed in the specifications and applications of Welded Steel Pipe products. Whether you need assistance with product selection, installation, or troubleshooting, our experts are here to help. We can provide detailed technical information, including specifications, performance data, and installation guidelines, to ensure the successful completion of your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to vast resources and expertise. This allows us to provide you with a seamless procurement experience, ensuring that you receive high-quality products that meet your specific needs. Our strong market presence in Togo enables us to offer valuable insights and expertise, helping you make informed decisions for your projects.

Whether you are in the construction, oil and gas, or infrastructure industry, we are confident that our Welded Steel Pipe products and services will meet your expectations. Contact us today to discuss your requirements and let us assist you in achieving your project goals in Togo.