All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the coating thickness affect the solderability of electrolytic tinplate coil?

The coating thickness of electrolytic tinplate coil directly affects the solderability of the material. A thicker coating can enhance solderability, as it provides a more stable and reliable surface for solder to adhere to. On the other hand, a thinner coating may result in poor solderability, as it may not offer enough protection against oxidation and may not provide sufficient bonding for solder joints. Therefore, achieving the optimal coating thickness is crucial to ensure good solderability in electrolytic tinplate coil.

How is the tin coating thickness variation measured on electrolytic tinplate coil?

The tin coating thickness variation on an electrolytic tinplate coil is typically measured using a non-destructive testing method called eddy current testing. This technique involves passing an alternating current through a coil and measuring the resulting magnetic field. The variations in the magnetic field caused by the variations in the tin coating thickness are then analyzed to determine the coating thickness at different points on the coil.

What are the common coil weights available for electrolytic tinplate coil?

The common coil weights available for electrolytic tinplate coil range from 1 to 10 metric tons.

Can the coil be used in renewable energy applications?

Yes, coils can be used in renewable energy applications. Coils are commonly used in various renewable energy technologies such as wind turbines, hydroelectric generators, and solar power systems to convert mechanical or electromagnetic energy into electrical energy.

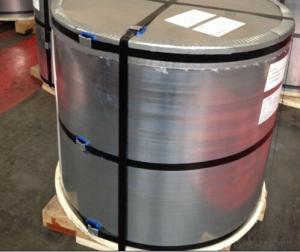

Wholesale Electrolytic Tinplate Coil from supplier in Slovenia

With our expertise in supplying Electrolytic Tinplate Coils to Slovenia, we are committed to providing comprehensive services to meet your needs. Whether you require sales assistance, quotations, or technical support, we are here to assist you throughout the procurement process.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the backing of a reputable and globally recognized organization. This enables us to offer reliable and high-quality Electrolytic Tinplate Coil products to our customers in Slovenia.

Our product range is extensive, ensuring that we can fulfill a wide range of requirements. From different sizes and thicknesses to various coatings and finishes, we have the right Electrolytic Tinplate Coil for your specific applications.

Furthermore, our years of market experience have provided us with valuable insights and expertise. We understand the unique challenges and requirements of the Slovenian market, allowing us to offer tailored solutions to meet your project needs.

By choosing us as your trusted partner, you can count on our commitment to delivering superior products and services. We prioritize customer satisfaction and strive to build long-term relationships based on trust and reliability.

Contact us today and let us become your go-to supplier for all your Electrolytic Tinplate Coil requirements in Slovenia.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the backing of a reputable and globally recognized organization. This enables us to offer reliable and high-quality Electrolytic Tinplate Coil products to our customers in Slovenia.

Our product range is extensive, ensuring that we can fulfill a wide range of requirements. From different sizes and thicknesses to various coatings and finishes, we have the right Electrolytic Tinplate Coil for your specific applications.

Furthermore, our years of market experience have provided us with valuable insights and expertise. We understand the unique challenges and requirements of the Slovenian market, allowing us to offer tailored solutions to meet your project needs.

By choosing us as your trusted partner, you can count on our commitment to delivering superior products and services. We prioritize customer satisfaction and strive to build long-term relationships based on trust and reliability.

Contact us today and let us become your go-to supplier for all your Electrolytic Tinplate Coil requirements in Slovenia.