All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

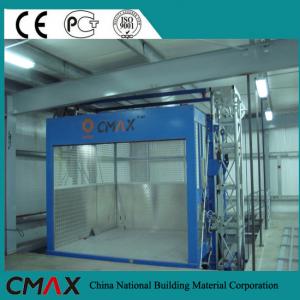

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different safety interlock systems used in building hoists?

There are several safety interlock systems used in building hoists, including emergency stop buttons, limit switches, slack rope switches, and overspeed governors. These systems are designed to ensure the safe operation of the hoist by detecting and responding to various potential hazards such as overspeed, slack rope, or emergency situations.

What are the energy consumption levels of a building hoist?

The energy consumption levels of a building hoist can vary depending on several factors, such as the type and size of the hoist, the weight being lifted, the height and speed of operation, and the efficiency of the hoist's motor. Generally, electric hoists tend to have lower energy consumption compared to hydraulic hoists. However, it is best to consult the specific manufacturer's specifications for accurate energy consumption levels of a particular building hoist model.

What are the different safety sensors or alarms used in building hoists?

There are several safety sensors and alarms used in building hoists to ensure the safety of workers and prevent accidents. Some of these include:

1. Overload sensors: These sensors detect if the hoist is carrying too much weight and can trigger an alarm or stop the hoist to prevent it from collapsing.

2. Overspeed sensors: These sensors monitor the speed of the hoist and can trigger an alarm or emergency brake if the hoist exceeds a safe speed limit.

3. Anti-collision sensors: These sensors detect the presence of obstacles or other hoists in the vicinity and can trigger an alarm or stop the hoist to prevent collisions.

4. Emergency stop buttons: These buttons are located in multiple areas of the hoist and allow workers to immediately stop the hoist in case of an emergency or unsafe situation.

5. Slack rope sensors: These sensors detect if the hoist's lifting rope becomes slack or loose, indicating a potential problem with the hoist's mechanism. An alarm can be triggered to prompt immediate inspection and repair.

6. Proximity sensors: These sensors are used to detect the presence of workers or objects near the hoist and can trigger an alarm or stop the hoist to prevent accidents.

Overall, these safety sensors and alarms play a crucial role in maintaining the safety of building hoists and protecting the well-being of workers.

Can a building hoist be used for transporting construction waste?

Yes, a building hoist can be used for transporting construction waste.

Wholesale Building Hoist from supplier in Romania

Our team of experts understands the specific needs of the construction industry in Romania and can provide tailored solutions to meet your requirements. We have a wide range of Building Hoist products available, including single and double cage hoists, as well as various lifting capacities.

In addition to supplying high-quality products, we also offer comprehensive technical support to ensure that your Building Hoists operate efficiently and safely. Our team of technicians is trained to provide maintenance and repair services, as well as training for your staff on how to operate the equipment properly.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources, including advanced technology and manufacturing facilities. This allows us to offer competitive pricing without compromising on quality.

We understand that each project has unique requirements, and we are committed to working closely with our clients to provide customized solutions. Whether you need a Building Hoist for a small-scale project or a large-scale construction site, we have the expertise and resources to meet your needs.

Contact us today to discuss your Building Hoist requirements and find out how we can support the success of your projects in Romania.

In addition to supplying high-quality products, we also offer comprehensive technical support to ensure that your Building Hoists operate efficiently and safely. Our team of technicians is trained to provide maintenance and repair services, as well as training for your staff on how to operate the equipment properly.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources, including advanced technology and manufacturing facilities. This allows us to offer competitive pricing without compromising on quality.

We understand that each project has unique requirements, and we are committed to working closely with our clients to provide customized solutions. Whether you need a Building Hoist for a small-scale project or a large-scale construction site, we have the expertise and resources to meet your needs.

Contact us today to discuss your Building Hoist requirements and find out how we can support the success of your projects in Romania.

Hot Search

- Suspended Platform in Nepal

- Cranes in Sri Lanka

- Concrete Machinery in Namibia

- Earthmoving Machinery in Albania

- Building Hoist in Vietnam

- Road Building Machinery in Thailand

- Concrete Machinery in Djibouti

- Building Hoist in Switzerland

- Earthmoving Machinery in Maldives

- Road Building Machinery in Nigeria