All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

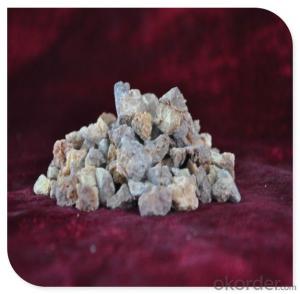

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How are alumina-silica and silica-alumina refractories distinguished from each other?

Alumina-silica and silica-alumina refractories are distinguished from each other based on the predominant composition of the materials. Alumina-silica refractories have a higher percentage of alumina compared to silica, whereas silica-alumina refractories have a higher percentage of silica compared to alumina. This difference in composition leads to variations in the refractory properties, such as thermal conductivity, thermal shock resistance, and chemical resistance, making them suitable for different applications in the field of high-temperature materials.

What are the advantages of using ytterbium oxide as a raw material in refractory production?

There are several advantages of using ytterbium oxide as a raw material in refractory production.

Firstly, ytterbium oxide has a high melting point, which makes it suitable for applications that require materials to withstand extreme temperatures. This property allows refractories made from ytterbium oxide to maintain their structural integrity and performance even at elevated temperatures.

Secondly, ytterbium oxide exhibits excellent thermal shock resistance, meaning it can withstand rapid changes in temperature without cracking or breaking. This is crucial in refractory production as refractories are often exposed to thermal cycling and abrupt temperature changes.

Additionally, ytterbium oxide has a low coefficient of thermal expansion. This property ensures that refractories made from ytterbium oxide maintain dimensional stability at different temperatures, reducing the risk of warping or distortion.

Moreover, ytterbium oxide has good chemical stability, making it resistant to corrosion and chemical reactions. This is particularly important in refractory applications involving aggressive chemical environments.

Lastly, ytterbium oxide is readily available and relatively cost-effective compared to other rare earth oxides. This makes it an attractive choice for refractory manufacturers, providing a cost-efficient solution without compromising on performance.

In summary, the advantages of using ytterbium oxide as a raw material in refractory production include its high melting point, excellent thermal shock resistance, low coefficient of thermal expansion, good chemical stability, and cost-effectiveness.

How do raw materials affect the resistance to carbon monoxide attack of refractory products?

Raw materials have a significant impact on the resistance to carbon monoxide attack of refractory products. The selection and quality of raw materials used in manufacturing refractories determine their ability to withstand carbon monoxide corrosion. Certain raw materials, such as high-purity alumina or silicon carbide, possess inherent resistance to carbon monoxide attack, making them ideal for constructing refractory products in environments where this gas is present. Additionally, the proper combination and composition of raw materials can enhance the refractory's resistance to carbon monoxide, ensuring its durability and longevity in such conditions.

Can you explain the role of serpentine in refractory materials?

Serpentine is a type of mineral that is commonly used as a binder in refractory materials. It helps to improve the strength and stability of the material, making it more resistant to high temperatures and chemical reactions. Serpentine also acts as a flux, promoting the fusion of other components in the refractory material during the manufacturing process. Overall, serpentine plays a crucial role in enhancing the performance and durability of refractory materials in various industrial applications.

Wholesale Raw Materials For Refractory from supplier in Mongolia

As a supplier of raw materials for refractory products in Mongolia, we offer a range of services to cater to our customers' needs. Our primary focus is on sales, quotations, and technical support for a diverse range of raw materials. Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have the capability to provide comprehensive procurement services for raw materials for refractory products in Mongolia.

In addition to our extensive product portfolio, we bring years of market development experience in Mongolia, which allows us to offer valuable insights and expertise for your projects. Our team understands the unique requirements and challenges of the Mongolian market, and we are well-equipped to assist you in sourcing the finest raw materials for refractory products.

Now, let us introduce Mongolia itself. This landlocked country is located in East Asia and is bordered by China and Russia. Known for its vast landscapes, Mongolia offers a wealth of natural beauty and cultural heritage. The nomadic culture, ancient traditions, and rich history of Mongolia make it a fascinating destination for exploration.

Some of the remarkable natural wonders in Mongolia include the Gobi Desert, the Altai Mountains, and the Khuvsgul Lake. These breathtaking landscapes provide unique opportunities for adventure and discovery. Mongolia's capital city, Ulaanbaatar, is a bustling hub of culture and commerce, blending modern development with traditional heritage.

Mongolia has emerged as an important player in various industries, including mining, agriculture, and tourism. The country's strategic location and diverse resources make it an attractive destination for investment and collaboration. Whether you are interested in exploring the natural beauty of Mongolia or seeking business opportunities, our team is here to assist you in sourcing the finest raw materials for refractory products and provide valuable support for your ventures in this enchanting country.

In addition to our extensive product portfolio, we bring years of market development experience in Mongolia, which allows us to offer valuable insights and expertise for your projects. Our team understands the unique requirements and challenges of the Mongolian market, and we are well-equipped to assist you in sourcing the finest raw materials for refractory products.

Now, let us introduce Mongolia itself. This landlocked country is located in East Asia and is bordered by China and Russia. Known for its vast landscapes, Mongolia offers a wealth of natural beauty and cultural heritage. The nomadic culture, ancient traditions, and rich history of Mongolia make it a fascinating destination for exploration.

Some of the remarkable natural wonders in Mongolia include the Gobi Desert, the Altai Mountains, and the Khuvsgul Lake. These breathtaking landscapes provide unique opportunities for adventure and discovery. Mongolia's capital city, Ulaanbaatar, is a bustling hub of culture and commerce, blending modern development with traditional heritage.

Mongolia has emerged as an important player in various industries, including mining, agriculture, and tourism. The country's strategic location and diverse resources make it an attractive destination for investment and collaboration. Whether you are interested in exploring the natural beauty of Mongolia or seeking business opportunities, our team is here to assist you in sourcing the finest raw materials for refractory products and provide valuable support for your ventures in this enchanting country.

Hot Search

- Monolithic Refractories in Tajikistan

- Ceramic Fiber Products in Fiji

- Refractory Bricks in Mozambique

- Raw Materials For Refractory in Ecuador

- Monolithic Refractories in Brazil

- Refractory Bricks in America

- Ceramic Fiber Products in Philippines

- Raw Materials For Refractory in Spain

- Ceramic Fiber Products in Bolivia

- Ceramic Fiber Products in Jamaica