All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

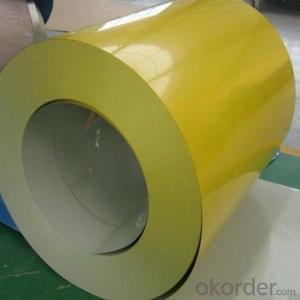

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

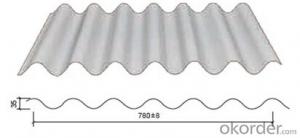

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the cold-rolling process affect the internal structure of steel?

The cold-rolling process compresses and elongates the steel, causing the grains within the material to realign and elongate in the direction of rolling. This results in a more uniform and refined grain structure, which enhances the mechanical properties of the steel, including increased strength and hardness. Additionally, cold-rolling reduces the size of any existing voids or defects within the steel, leading to improved overall quality and dimensional accuracy.

What are the considerations for designing with pre-painted cold-rolled steel?

When designing with pre-painted cold-rolled steel, there are several key considerations to keep in mind. Firstly, it is important to understand the specific properties and limitations of pre-painted steel, such as its resistance to corrosion, durability, and color retention. This knowledge will help in selecting the appropriate grade and thickness of pre-painted steel for the intended application.

Secondly, the design should account for the manufacturing process of pre-painted steel, which involves coating the steel with a layer of paint or coating material. The design should ensure proper adhesion of the coating to the steel substrate, as well as consider any potential issues with chipping, cracking, or peeling of the paint during fabrication, installation, or long-term use.

Another consideration is the color and aesthetics of the pre-painted steel. Designers should carefully choose the color and finish of the pre-painted steel to align with the desired visual appeal and overall design concept. It is also crucial to select coatings that are suitable for the intended environment and can withstand exposure to various weather conditions, UV radiation, and chemicals if required.

Additionally, the design should factor in any specific requirements for the pre-painted steel, such as fire resistance, thermal insulation, or acoustic properties. These considerations may influence the choice of coating materials, thickness, or additional layers that need to be incorporated into the design.

Lastly, it is essential to collaborate with experienced suppliers or manufacturers of pre-painted cold-rolled steel during the design process. Their expertise can provide valuable insights and guidance on material selection, fabrication techniques, and any limitations or specific recommendations for designing with pre-painted steel.

What surface treatments are commonly applied to cold-rolled steel, and how do they enhance performance?

Common surface treatments applied to cold-rolled steel include galvanization, electroplating, and powder coating. These treatments enhance the performance of the steel by providing corrosion resistance, improved aesthetics, and increased durability. Galvanization involves coating the steel with a layer of zinc, which acts as a sacrificial barrier against corrosion. Electroplating uses an electric current to deposit a thin layer of metal such as chrome or nickel onto the steel, offering enhanced resistance to wear and corrosion. Powder coating involves applying a dry powder to the steel surface, which is then baked to form a protective, durable, and attractive finish. Overall, these surface treatments extend the lifespan of cold-rolled steel and improve its appearance, making it suitable for a wide range of applications.

Wholesale Cold Rolled Steel from supplier in Lithuania

We are a Cold Rolled Steel supplier serving the Lithuania, mainly engaged in the sale, quotation, and technical support services of various Cold Rolled Steel products in the Lithuania region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Cold Rolled Steel procurement services in the Lithuania. Not only do we have a wide range of Cold Rolled Steel products, but after years of market development in the Lithuania, we can also provide valuable experience for your projects.