All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

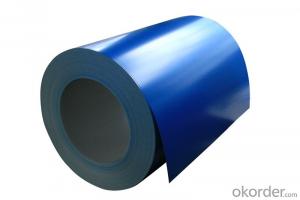

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you test the corrosion resistance of coated aluminum coils in harsh environments?

To test the corrosion resistance of coated aluminum coils in harsh environments, a series of laboratory tests and field trials can be conducted. Firstly, a salt spray test can be performed, where the coils are exposed to a salt fog chamber to simulate the effects of coastal or marine environments. This test allows for the evaluation of the coating's ability to withstand corrosion caused by saltwater exposure.

Additionally, a humidity test can be conducted, subjecting the coils to high humidity levels for an extended period. This test helps assess the coating's resistance to moisture-induced corrosion.

To simulate outdoor exposure, coated aluminum coils can also be subjected to accelerated weathering tests, such as UV exposure or cyclic corrosion tests. These tests expose the coils to extreme temperature variations, UV radiation, and corrosive agents to evaluate their durability in harsh environments.

Furthermore, field trials can be conducted by installing the coated aluminum coils in real-world settings, such as industrial or coastal areas, for an extended period. This allows for the evaluation of long-term corrosion resistance in the specific environment the coils are intended to be used.

By combining laboratory tests and field trials, it is possible to thoroughly assess the corrosion resistance of coated aluminum coils in harsh environments and ensure their reliability and durability in such conditions.

How are aluminum coils used in the construction of aluminum boats?

Aluminum coils are commonly used in the construction of aluminum boats as they are the primary material for building the hulls and other structural components. The coils are typically shaped, cut, and welded to form the desired boat shape, providing strength, durability, and lightweight characteristics essential for marine applications.

What are the different temper designations for aluminum coils?

The different temper designations for aluminum coils include H12, H14, H16, H18, H22, H24, H26, H28, H32, H34, H36, H38, T4, T6, T651, and O. These designations represent different levels of hardness, strength, and formability of the aluminum coils.

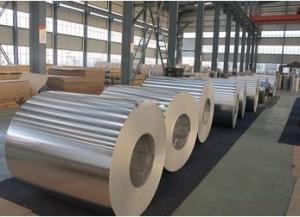

How do you prevent aluminum coil surface damage during storage?

To prevent aluminum coil surface damage during storage, it is important to follow a few key steps. Firstly, ensure that the storage area is clean, dry, and free from any contaminants that could potentially scratch or damage the surface of the coil. It is also crucial to protect the coil from exposure to moisture, as it can cause corrosion and discoloration. Cover the coil with a protective material, such as plastic or a specialized coil cover, to shield it from dust, dirt, and moisture. Additionally, avoid stacking heavy objects on top of the coil, as this could result in denting or deformation. Proper handling and gentle placement of the coil during storage will also help prevent any surface damage.

Wholesale Aluminum Coils from supplier in Liechtenstein

With our strong commitment to quality and customer satisfaction, we strive to meet and exceed all your requirements for Aluminum Coils in Liechtenstein. Our team of experienced professionals is dedicated to providing you with personalized solutions and excellent service. Whether you need standard or customized Aluminum Coils, we have the capabilities to meet your specific needs.

As a trusted supplier, we understand the importance of timely delivery and competitive pricing. We work closely with our logistics partners to ensure that your orders are delivered on time, every time. Our competitive pricing ensures that you receive the best value for your investment.

Furthermore, our technical support team is always ready to assist you with any inquiries or technical issues you may have. We are committed to providing you with the highest level of support, ensuring that your projects run smoothly and efficiently.

Partnering with us means gaining access to a wide range of high-quality Aluminum Coils and receiving exceptional service throughout the entire process. We are dedicated to building long-term relationships with our customers, and we look forward to serving you in Liechtenstein.

As a trusted supplier, we understand the importance of timely delivery and competitive pricing. We work closely with our logistics partners to ensure that your orders are delivered on time, every time. Our competitive pricing ensures that you receive the best value for your investment.

Furthermore, our technical support team is always ready to assist you with any inquiries or technical issues you may have. We are committed to providing you with the highest level of support, ensuring that your projects run smoothly and efficiently.

Partnering with us means gaining access to a wide range of high-quality Aluminum Coils and receiving exceptional service throughout the entire process. We are dedicated to building long-term relationships with our customers, and we look forward to serving you in Liechtenstein.