All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

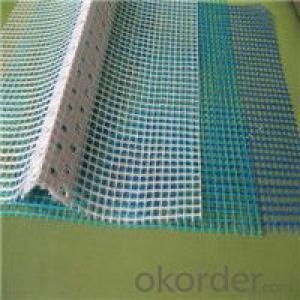

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

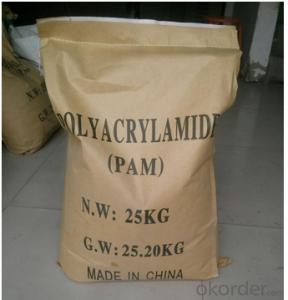

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

Can fiberglass be used for making art installations?

Yes, fiberglass can be used for making art installations. Its versatility, durability, and lightweight nature make it a popular choice among artists for creating large-scale installations that require strength and resilience. Additionally, fiberglass can be easily molded and shaped into various forms, allowing artists to bring their creative visions to life.

Can fiberglass supply be used for consumer products?

Yes, fiberglass supply can be used for consumer products. Fiberglass is a versatile material that has a wide range of applications in various industries, including consumer goods. It is commonly used in the manufacturing of products such as boats, automobiles, furniture, bathtubs, and even home insulation. The properties of fiberglass, including its strength, durability, and resistance to corrosion, make it suitable for use in consumer products where these qualities are desired.

Can fiberglass be used for making water features?

Yes, fiberglass can be used for making water features. Its lightweight and durable properties make it a popular choice for constructing waterfalls, ponds, and other decorative water elements. Additionally, fiberglass is resistant to water, making it suitable for long-term exposure to moisture without degradation.

How is fiberglass affected by temperature changes?

Fiberglass is minimally affected by temperature changes. It has a low coefficient of thermal expansion, meaning it does not expand or contract significantly with temperature fluctuations. This property makes fiberglass suitable for various applications, including insulation, construction, and automotive parts.

Can fiberglass be made antimicrobial?

Yes, fiberglass can be made antimicrobial by incorporating antimicrobial agents during the manufacturing process, such as using antimicrobial coatings or additives. These agents help inhibit the growth and spread of microorganisms on the surface of fiberglass, making it resistant to bacteria, fungi, and other microbes.

Wholesale Fiberglass Supply from supplier in Japan

At our company, we understand that our customers in Japan have unique needs and preferences when it comes to fiberglass supplies. That's why we have spent years building strong relationships with local manufacturers and suppliers, ensuring that we can offer a diverse and high-quality range of products.

Whether you need fiberglass materials, equipment, or accessories, we have everything you need for your projects. Our team of experts is always up-to-date with the latest industry trends and technological advancements, so we can provide you with valuable insights and guidance to help you make informed decisions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to offer convenient and efficient one-stop procurement services. This means that you can rely on us to handle everything from sales to quotations and technical support, making your procurement process smooth and hassle-free.

Our dedication to delivering exceptional products, services, and support is what sets us apart. We are committed to helping you achieve optimal results and maximize the efficiency of your operations. Trust us to be your reliable partner for all your fiberglass supply needs in Japan.

Contact us today to discuss your requirements and let us assist you in achieving your goals.

Whether you need fiberglass materials, equipment, or accessories, we have everything you need for your projects. Our team of experts is always up-to-date with the latest industry trends and technological advancements, so we can provide you with valuable insights and guidance to help you make informed decisions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to offer convenient and efficient one-stop procurement services. This means that you can rely on us to handle everything from sales to quotations and technical support, making your procurement process smooth and hassle-free.

Our dedication to delivering exceptional products, services, and support is what sets us apart. We are committed to helping you achieve optimal results and maximize the efficiency of your operations. Trust us to be your reliable partner for all your fiberglass supply needs in Japan.

Contact us today to discuss your requirements and let us assist you in achieving your goals.