All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

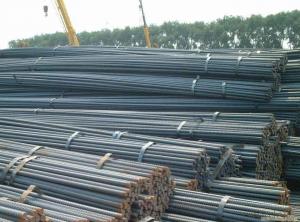

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

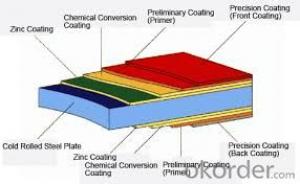

- - Cold Rolled Steel

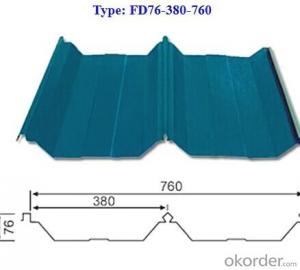

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is cold-rolled steel used in the manufacturing of power transmission and distribution equipment?

Cold-rolled steel is commonly used in the manufacturing of power transmission and distribution equipment due to its superior strength, durability, and precision. It is often used for components such as transformers, power poles, cable trays, and busbars. The cold-rolling process enhances the steel's mechanical properties, making it more resistant to corrosion, bending, and wear. Additionally, the smooth and uniform surface finish achieved through cold-rolling ensures precise fitting and efficient functioning of the equipment.

What are the quality control measures in place to maintain the integrity of cold-rolled steel products?

There are several quality control measures implemented to ensure the integrity of cold-rolled steel products. One important measure is the use of advanced testing equipment and techniques to detect any defects or abnormalities in the steel, such as surface imperfections, thickness variations, or mechanical properties. Additionally, strict adherence to industry standards and specifications throughout the manufacturing process helps maintain consistency and reliability of the products. Regular inspections and audits are conducted to monitor the production procedures, including material handling, storage, and transportation, to ensure proper handling and prevent contamination or damage. Finally, comprehensive documentation and traceability systems are established to track the entire manufacturing process, from raw material procurement to the final product, enabling effective quality control and accountability.

What is the role of cold-rolled steel in the manufacturing of transportation and logistics equipment?

Cold-rolled steel plays a critical role in the manufacturing of transportation and logistics equipment. It offers superior strength, durability, and dimensional precision, making it ideal for constructing various components such as frames, chassis, panels, and support structures. The cold-rolling process enhances the steel's mechanical properties, enabling it to withstand heavy loads, impacts, and harsh environmental conditions commonly encountered in transportation and logistics operations. Additionally, its smooth and uniform surface finish facilitates efficient welding, painting, and coating, further enhancing the aesthetics and corrosion resistance of the equipment. Overall, cold-rolled steel is a vital material that ensures the structural integrity and longevity of transportation and logistics equipment.

What are the environmental implications of cold-rolled steel production?

The environmental implications of cold-rolled steel production include high energy consumption, greenhouse gas emissions, water pollution, and waste generation. The process requires significant amounts of electricity and fossil fuels, contributing to carbon dioxide emissions and climate change. Water pollution occurs due to the use of chemicals in pickling and cleaning steel, which can contaminate nearby water bodies. Additionally, the production generates waste materials such as sludge, scale, and dust that require proper disposal or treatment. Overall, cold-rolled steel production has negative environmental impacts, highlighting the need for sustainable practices and alternative materials in the manufacturing industry.

Wholesale Cold Rolled Steel from supplier in Jamaica

We are a Cold Rolled Steel supplier serving the Jamaica, mainly engaged in the sale, quotation, and technical support services of various Cold Rolled Steel products in the Jamaica region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Cold Rolled Steel procurement services in the Jamaica. Not only do we have a wide range of Cold Rolled Steel products, but after years of market development in the Jamaica, we can also provide valuable experience for your projects.