All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

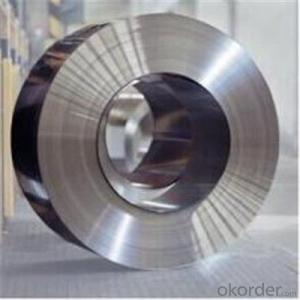

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel strips used in the production of fencing and security barriers?

Steel strips are used in the production of fencing and security barriers as they provide strength and durability. These strips are typically formed into various shapes, such as posts, rails, and panels, which are then assembled to create the structure. The steel strips ensure the fencing or barrier is sturdy and resistant to tampering or damage, enhancing its effectiveness in providing security and protection.

What is the process of coil coating and why is it applied to steel strips?

The process of coil coating involves applying a protective layer or coating on steel strips. It is done by cleaning and treating the surface of the steel strip, followed by the application of a primer coat and then a topcoat. The coated steel strip is then cured or baked to ensure adhesion and durability.

Coil coating is applied to steel strips for various reasons. Firstly, it enhances the corrosion resistance of the steel, extending its lifespan in various environments. Secondly, it improves the aesthetics of the steel by providing a decorative finish, making it suitable for architectural and decorative applications. Additionally, coil coating provides a consistent and uniform coating thickness, ensuring even protection throughout the steel strip. It also offers the flexibility to choose from a wide range of colors, textures, and finishes as per the requirements of the end-use application. Overall, coil coating enhances the performance, durability, and visual appeal of steel strips, making them suitable for a wide range of industries such as construction, automotive, and appliances.

How are steel strips applied in the creation of efficient and eco-friendly public transportation systems?

Steel strips are used in the creation of efficient and eco-friendly public transportation systems in various ways. They are commonly used as reinforcement in the construction of lightweight but sturdy vehicle structures, ensuring safety and durability. Additionally, steel strips are often utilized in the manufacturing of rail tracks, providing a strong and reliable foundation for trains and trams. By using steel strips, public transportation systems can enhance their efficiency, reduce maintenance costs, and contribute to a greener environment through sustainable and long-lasting infrastructure.

What are the requirements for steel strips used in the food industry?

The requirements for steel strips used in the food industry include being made from food-grade stainless steel, having a smooth and non-porous surface to prevent bacterial growth, being resistant to corrosion and chemical reactions with food, and meeting specific hygiene and safety standards set by regulatory bodies.

Wholesale Steel Strips from supplier in Iceland

Our commitment to quality is unwavering, and we only source Steel Strips from trusted manufacturers who meet international standards. This ensures that our products are of the highest quality and will meet your project requirements. We also offer customization options, allowing you to tailor the Steel Strips to your specific needs.

Our sales team is dedicated to providing exceptional customer service and will work closely with you to understand your requirements and provide you with the best solution. We are committed to timely delivery and can arrange efficient logistics to ensure that your Steel Strips are delivered to you on time.

As a subsidiary of CNBM, we have access to a wide network of resources and expertise. This allows us to provide you with competitive pricing and cost-effective solutions for your Steel Strips procurement needs. Our technical support team is also available to assist you with any queries or issues you may have, ensuring a smooth and seamless experience.

Choose us as your trusted partner for all your Steel Strips needs in Iceland. Contact us today to discuss your requirements and let us provide you with the best solution for your project.

Our sales team is dedicated to providing exceptional customer service and will work closely with you to understand your requirements and provide you with the best solution. We are committed to timely delivery and can arrange efficient logistics to ensure that your Steel Strips are delivered to you on time.

As a subsidiary of CNBM, we have access to a wide network of resources and expertise. This allows us to provide you with competitive pricing and cost-effective solutions for your Steel Strips procurement needs. Our technical support team is also available to assist you with any queries or issues you may have, ensuring a smooth and seamless experience.

Choose us as your trusted partner for all your Steel Strips needs in Iceland. Contact us today to discuss your requirements and let us provide you with the best solution for your project.