All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the safety regulations for working with aluminum profiles in construction and industry?

The safety regulations for working with aluminum profiles in construction and industry generally include:

1. Personal Protective Equipment (PPE): Workers should wear appropriate PPE, such as safety glasses, gloves, and steel-toed boots, to protect themselves from potential hazards.

2. Training and Education: Workers should receive proper training on handling aluminum profiles, including understanding the risks associated with the material and learning safe work practices.

3. Handling and Storage: Aluminum profiles should be stored in a designated area, ensuring they are stacked and secured properly to prevent accidents. Workers should use appropriate lifting techniques and equipment to avoid injuries while handling the profiles.

4. Cutting and Machining: When cutting or machining aluminum profiles, workers should use appropriate tools and machinery with safety guards in place. Proper ventilation should be provided to minimize exposure to aluminum dust or fumes.

5. Fire Safety: Aluminum profiles are flammable, and therefore, fire safety measures should be in place, including fire extinguishers, adequate escape routes, and regular fire safety drills.

6. Electrical Safety: Workers should be aware of electrical hazards when working with aluminum profiles near electrical equipment or power sources. Proper grounding and insulation should be ensured to prevent accidents.

7. Fall Protection: When working at heights, workers should use appropriate fall protection equipment, such as harnesses and guardrails, to prevent falls and injuries.

It is important to note that specific safety regulations may vary depending on the region, industry, and specific tasks involved. It is essential to refer to local regulations and consult with experts to ensure compliance and enhance safety when working with aluminum profiles.

What is the expected service life of aluminum profiles used in various outdoor applications?

The expected service life of aluminum profiles used in various outdoor applications can vary depending on several factors such as environmental conditions, maintenance practices, and the quality of the aluminum used. However, on average, aluminum profiles can last anywhere from 20 to 50 years in outdoor applications before showing signs of deterioration or requiring replacement.

How do you protect aluminum profiles from corrosion in aggressive marine environments?

To protect aluminum profiles from corrosion in aggressive marine environments, several measures can be taken. Firstly, applying a protective coating such as anodizing or powder coating can provide a barrier against the corrosive elements. Additionally, using stainless steel fasteners instead of regular steel can prevent galvanic corrosion. Regular maintenance, including cleaning and inspection of the profiles, is crucial to identify any signs of corrosion and address them promptly. Lastly, implementing proper drainage and ventilation systems can help minimize exposure to moisture and saltwater, further reducing the risk of corrosion.

What are the applications of aluminum profiles in construction?

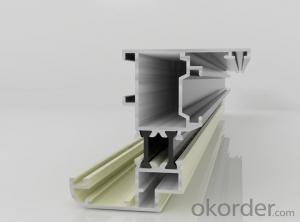

Aluminum profiles are extensively used in construction for various applications including window frames, door frames, curtain walls, roofing systems, cladding, and structural components. They offer excellent strength-to-weight ratio, corrosion resistance, and durability. Moreover, aluminum profiles can be easily fabricated, allowing for flexible and customized designs. Their thermal and acoustic insulation properties also make them suitable for energy-efficient constructions. Overall, aluminum profiles play a vital role in enhancing the aesthetics, functionality, and sustainability of modern construction projects.

Wholesale Aluminum Profiles from supplier in Guinea

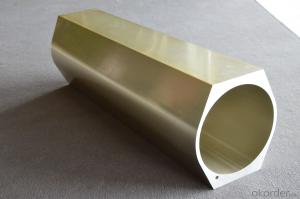

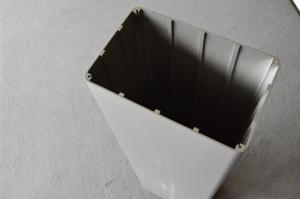

Whether you are in need of standard profiles or customized solutions, our team of experts is dedicated to providing you with high-quality Aluminum Profiles that meet your specific requirements. We have a wide range of profiles available, including but not limited to, windows and doors profiles, curtain wall profiles, industrial profiles, and decorative profiles.

With our strong network and partnerships with reputable manufacturers, we are able to offer competitive prices without compromising on quality. Our dedicated procurement team works closely with our customers to understand their project needs and provide the best possible solutions.

In addition to our sales services, we also provide comprehensive technical support throughout the entire process. Our team of engineers is available to assist with product selection, installation guidance, and troubleshooting, ensuring that your project is executed smoothly and efficiently.

At our company, we prioritize customer satisfaction and strive to build long-term relationships with our clients. We believe in delivering value beyond just the products we supply, which is why we offer reliable after-sales support and assistance.

With our extensive product range, market experience, and commitment to customer satisfaction, we are confident that we can meet all your Aluminum Profiles needs in Guinea. Contact us today for a quotation or any inquiries, and let us be your trusted partner for all your Aluminum Profiles requirements.

With our strong network and partnerships with reputable manufacturers, we are able to offer competitive prices without compromising on quality. Our dedicated procurement team works closely with our customers to understand their project needs and provide the best possible solutions.

In addition to our sales services, we also provide comprehensive technical support throughout the entire process. Our team of engineers is available to assist with product selection, installation guidance, and troubleshooting, ensuring that your project is executed smoothly and efficiently.

At our company, we prioritize customer satisfaction and strive to build long-term relationships with our clients. We believe in delivering value beyond just the products we supply, which is why we offer reliable after-sales support and assistance.

With our extensive product range, market experience, and commitment to customer satisfaction, we are confident that we can meet all your Aluminum Profiles needs in Guinea. Contact us today for a quotation or any inquiries, and let us be your trusted partner for all your Aluminum Profiles requirements.