All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

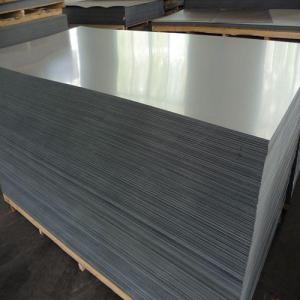

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can tinplate containers be used for acidic products?

Tinplate containers can be used for acidic products, as tin is resistant to corrosion from most acids. However, it is important to ensure that the tin coating is of high quality and intact to prevent any potential reaction between the acidic product and the underlying steel.

How is tinplate used in the production of decorative collectibles?

Tinplate is commonly used in the production of decorative collectibles due to its versatility and aesthetic appeal. It is often employed as a base material, providing a sturdy structure for various decorative elements such as embossing, etching, and intricate designs. Tinplate's corrosion resistance properties ensure the longevity of these collectibles, making them highly sought after by collectors. Additionally, its ability to be easily molded and shaped allows for the creation of unique and intricate designs, further enhancing the visual appeal of the collectibles.

How is tinplate used in the aerospace industry for lightweight and durable components?

Tinplate is commonly used in the aerospace industry for lightweight and durable components due to its unique combination of properties. Its high strength-to-weight ratio makes it an ideal choice for constructing various parts of aircraft, such as fuel tanks, engine components, and structural elements. The thin layer of tin coating on the steel substrate provides corrosion resistance, preventing the formation of rust and ensuring durability even in challenging environments. Additionally, tinplate's excellent formability allows for complex shapes and intricate designs, allowing for efficient manufacturing processes. Overall, tinplate's lightweight nature, durability, corrosion resistance, and formability make it an indispensable material in the aerospace industry.

What are the challenges of working with tinplate in manufacturing?

One of the main challenges of working with tinplate in manufacturing is its susceptibility to corrosion. Tinplate can easily rust if not properly handled or protected, which can lead to product damage or deterioration. Additionally, tinplate is relatively heavy compared to other materials used in manufacturing, making it more difficult to handle and transport. Another challenge is the limited availability of tinplate, as it is not as widely produced as other metals. Therefore, manufacturers may face supply chain issues or higher costs associated with sourcing tinplate. Overall, addressing corrosion, managing weight, and ensuring a stable supply are some of the key challenges when working with tinplate in manufacturing.

Wholesale Tinplate from supplier in Guinea Bissau

We are a Tinplate supplier serving the Guinea Bissau, mainly engaged in the sale, quotation, and technical support services of various Tinplate products in the Guinea Bissau region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Tinplate procurement services in the Guinea Bissau. Not only do we have a wide range of Tinplate products, but after years of market development in the Guinea Bissau, we can also provide valuable experience for your projects.