All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

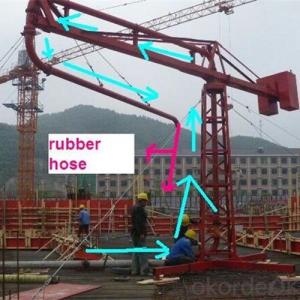

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is a concrete batching system?

A concrete batching system is a set of equipment and processes used to mix and produce concrete in large quantities. It includes various components such as aggregate storage bins, cement silos, water storage tanks, conveyors, and mixers. The system is designed to accurately measure and proportion the ingredients of concrete, ensuring consistency and quality in the final product.

What are the different types of concrete batch plants?

There are several different types of concrete batch plants, including stationary plants, mobile plants, and central mix plants. Stationary plants are fixed in one location and are typically used for large-scale projects. Mobile plants, on the other hand, can be easily transported and are commonly used for smaller projects or remote locations. Central mix plants combine all the ingredients of concrete, including water, in a central location before being transported to the construction site.

How to choose the right concrete screed machine for specific needs?

To choose the right concrete screed machine for specific needs, it is important to consider several factors. Firstly, assess the size and scope of the project to determine the required machine capacity and power. Consider the type of surface you will be working on, as different machines are designed for various applications such as flooring, roadwork, or leveling. Additionally, consider the desired finish and accuracy of the screeding process, as some machines offer more advanced features for better precision. It is also crucial to take into account the budget and availability of the machine, ensuring that it aligns with the specific needs and requirements of the project. Researching and comparing different models, reading customer reviews, and consulting with professionals in the field can help in making an informed decision.

How does a concrete pipe making machine work?

A concrete pipe making machine works by combining cement, aggregates, and water to create a concrete mixture. This mixture is then poured into a mold or form, which is usually made of steel or plastic. The machine applies pressure or vibration to the mold to ensure the even distribution of the concrete and to remove any air bubbles. Once the concrete is properly compacted, it is left to cure and harden. After a certain period, the mold is opened, and the concrete pipe is removed. The machine's efficiency and precision contribute to the production of high-quality and durable concrete pipes.

Wholesale Concrete Machinery from supplier in France

We guarantee that our Concrete Machinery products are of the highest quality and adhere to all industry standards. Our team of experts is always available to provide technical support and assist with any queries or concerns you may have.

Furthermore, we offer comprehensive after-sales services, including maintenance and repair, to ensure the longevity and optimal performance of your Concrete Machinery. We are committed to building long-term relationships with our customers and providing ongoing support throughout the lifespan of your equipment.

At our company, we prioritize sustainability and environmental responsibility. Our Concrete Machinery products are designed to be energy-efficient and environmentally friendly, reducing carbon emissions and minimizing the impact on the environment.

We are proud to be a part of CNBM, a global leader in the construction materials industry. This affiliation allows us to leverage the resources and expertise of CNBM to deliver exceptional value to our customers in France.

Contact us today to discuss your Concrete Machinery requirements and let us provide you with the best solutions for your projects. Trust us as your reliable partner for all your Concrete Machinery needs in France.

Furthermore, we offer comprehensive after-sales services, including maintenance and repair, to ensure the longevity and optimal performance of your Concrete Machinery. We are committed to building long-term relationships with our customers and providing ongoing support throughout the lifespan of your equipment.

At our company, we prioritize sustainability and environmental responsibility. Our Concrete Machinery products are designed to be energy-efficient and environmentally friendly, reducing carbon emissions and minimizing the impact on the environment.

We are proud to be a part of CNBM, a global leader in the construction materials industry. This affiliation allows us to leverage the resources and expertise of CNBM to deliver exceptional value to our customers in France.

Contact us today to discuss your Concrete Machinery requirements and let us provide you with the best solutions for your projects. Trust us as your reliable partner for all your Concrete Machinery needs in France.