All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

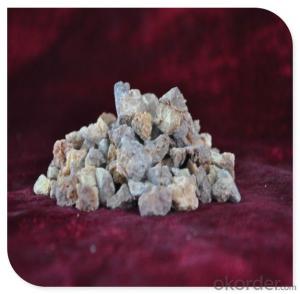

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials perform in electric arc furnaces?

Refractory materials perform exceptionally well in electric arc furnaces due to their high heat resistance and ability to withstand extreme temperatures. They help to contain the intense heat generated during the melting process, preventing damage to the furnace structure and ensuring efficient operation. Refractory materials also provide insulation, reducing heat loss and optimizing energy efficiency. Additionally, they resist chemical reactions with molten metals and slag, enhancing the overall durability and lifespan of the furnace.

What are the refractory materials used in the glass fiber industry?

The refractory materials commonly used in the glass fiber industry include alumina, zirconia, silica, magnesia, and chrome oxide. These materials are chosen for their high melting points, resistance to thermal shock, and ability to withstand the harsh conditions of glass fiber production processes.

How are refractory fibers used in insulation?

Refractory fibers are used in insulation as they possess excellent thermal resistance and can withstand high temperatures. They are typically woven or layered together to create insulating materials that can be used in various applications such as furnaces, kilns, and high-temperature equipment. These fibers trap air or gases within their structure, minimizing heat transfer and providing effective insulation.

Wholesale Refractory Materials from supplier in Fiji

Whether you are in the steel, cement, glass, or other industries, we have the expertise and resources to meet your specific requirements. Our team of experienced professionals will work closely with you to understand your needs and recommend the most suitable refractory materials for your applications.

We offer a wide range of refractory products, including bricks, castables, mortars, and insulation materials. Our products are sourced from trusted manufacturers and undergo rigorous quality control to ensure their reliability and performance.

In addition to our comprehensive product range, we also provide value-added services such as sales support, quotation assistance, and technical guidance. Our knowledgeable team is always ready to answer any questions you may have and provide recommendations based on your project requirements.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to stay at the forefront of industry developments and offer the latest advancements in refractory materials.

At our company, we prioritize customer satisfaction and aim to build long-term relationships with our clients. We understand the importance of timely delivery and strive to ensure that your refractory materials are delivered on schedule.

Whether you require refractory materials for new installations, maintenance, or repair projects, we are your trusted partner in Fiji. Contact us today to discuss your requirements and experience our exceptional products and services.

We offer a wide range of refractory products, including bricks, castables, mortars, and insulation materials. Our products are sourced from trusted manufacturers and undergo rigorous quality control to ensure their reliability and performance.

In addition to our comprehensive product range, we also provide value-added services such as sales support, quotation assistance, and technical guidance. Our knowledgeable team is always ready to answer any questions you may have and provide recommendations based on your project requirements.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to stay at the forefront of industry developments and offer the latest advancements in refractory materials.

At our company, we prioritize customer satisfaction and aim to build long-term relationships with our clients. We understand the importance of timely delivery and strive to ensure that your refractory materials are delivered on schedule.

Whether you require refractory materials for new installations, maintenance, or repair projects, we are your trusted partner in Fiji. Contact us today to discuss your requirements and experience our exceptional products and services.

Hot Search

- Monolithic Refractories in Bangladesh

- Ceramic Fiber Products in Nicaragua

- Refractory Bricks in Cambodia

- Raw Materials For Refractory in Papua New Guinea

- Monolithic Refractories in Greece

- Raw Materials For Refractory in Netherlands

- Monolithic Refractories in Liechtenstein

- Refractory Bricks in Tunisia

- Monolithic Refractories in Laos

- Raw Materials For Refractory in France