All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the difference between a ductile iron mechanical joint and a flanged joint?

A ductile iron mechanical joint is a type of joint used to connect ductile iron pipes, where the joint is created by compressing a rubber gasket between two pipe ends and securing them with mechanical devices like bolts and nuts. On the other hand, a flanged joint is a type of joint used to connect pipes, valves, or other equipment, where the joint is created by bolting together two flanges with a gasket in between. The main difference between the two is the method of connection, with a mechanical joint relying on compression and mechanical devices, while a flanged joint relies on bolting together two flanges.

What are the different joining methods for ductile iron pipe fittings?

The different joining methods for ductile iron pipe fittings include mechanical joints, flanged joints, and push-on joints. Mechanical joints are typically used for smaller diameter pipes and involve a gasket and bolts to create a tight seal. Flanged joints are used for larger diameter pipes and involve bolting two flanges together with a gasket in between. Push-on joints use a rubber gasket and lubricant to create a tight seal by pushing the pipe into the fitting.

Are there any limitations to the use of ductile iron pipe fittings?

Yes, there are limitations to the use of ductile iron pipe fittings. One limitation is their susceptibility to corrosion when exposed to certain environments. Additionally, ductile iron fittings may not be suitable for applications that require high levels of flexibility or where frequent disassembly is needed due to their relatively rigid nature. Finally, ductile iron fittings may not be recommended for use in systems that operate at extremely high or low temperatures as they may become brittle or lose their structural integrity.

Can ductile iron pipe fittings be used for potable water systems?

Yes, ductile iron pipe fittings can be used for potable water systems. Ductile iron is a durable and corrosion-resistant material that meets the necessary standards for drinking water applications.

Wholesale Ductile Iron Pipe Fittings from supplier in Ethiopia

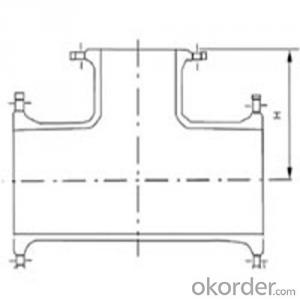

Whether you are in the construction, water supply, or industrial sector, our Ductile Iron Pipe Fittings are designed to meet the highest quality standards and provide reliable performance. We offer a wide range of fittings, including bends, tees, reducers, flanges, and more, to ensure that you find the perfect fit for your specific application.

As a subsidiary of CNBM, we have access to a global network of suppliers, ensuring that we can source the best products at competitive prices. Our team of experts is dedicated to providing you with personalized service and support throughout the procurement process, from initial inquiry to final delivery.

In addition to our product offering, we also provide value-added services such as technical support, project consulting, and logistical assistance. Our team has in-depth knowledge of the Ethiopian market and can help you navigate any challenges or regulations that may arise during your project.

At CNBM, we prioritize customer satisfaction and strive to exceed your expectations. We are committed to building long-term partnerships with our clients and believe in delivering exceptional quality and service every step of the way.

Contact us today to discuss your Ductile Iron Pipe Fittings requirements in Ethiopia and let us help you find the best solution for your project.

As a subsidiary of CNBM, we have access to a global network of suppliers, ensuring that we can source the best products at competitive prices. Our team of experts is dedicated to providing you with personalized service and support throughout the procurement process, from initial inquiry to final delivery.

In addition to our product offering, we also provide value-added services such as technical support, project consulting, and logistical assistance. Our team has in-depth knowledge of the Ethiopian market and can help you navigate any challenges or regulations that may arise during your project.

At CNBM, we prioritize customer satisfaction and strive to exceed your expectations. We are committed to building long-term partnerships with our clients and believe in delivering exceptional quality and service every step of the way.

Contact us today to discuss your Ductile Iron Pipe Fittings requirements in Ethiopia and let us help you find the best solution for your project.

Hot Search

- Ductile Iron Pipes in Slovakia

- Ductile Iron Pipe Fittings in Niue

- Ductile Iron Pipes in Germany

- Ductile Iron Pipes in Zimbabwe

- Ductile Iron Pipe Fittings in Slovenia

- Ductile Iron Pipe Fittings in Iceland

- Ductile Iron Pipe Fittings in Papua New Guinea

- Ductile Iron Pipes in Vanuatu

- Ductile Iron Pipes in Tanzania

- Ductile Iron Pipes in Serbia