All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

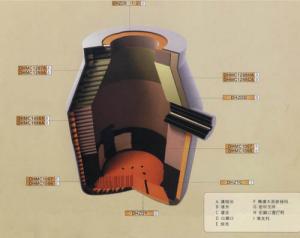

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractory bricks contribute to the safety of industrial processes?

Refractory bricks contribute to the safety of industrial processes by providing insulation and resistance to high temperatures, preventing heat transfer and protecting the surrounding structures and equipment from damage. They also have excellent chemical resistance, ensuring that they can withstand corrosive substances and prevent leaks or explosions. Additionally, their high strength and durability help maintain structural integrity, reducing the risk of accidents and ensuring the overall safety of the industrial processes.

What are the common refractory brick shapes used in steelmaking?

The common refractory brick shapes used in steelmaking include standard bricks, chamfered bricks, wedge bricks, and special shapes such as burner blocks, checker bricks, and purging plugs.

Can refractory bricks be used in shipbuilding industry?

Yes, refractory bricks can be used in the shipbuilding industry. They are commonly used in areas of high temperature and heat, such as furnaces, boilers, and exhaust systems, to provide insulation and resistance to the extreme conditions. In shipbuilding, refractory bricks can be used in the construction of marine boilers, incinerators, and other heat-intensive equipment to ensure safety and durability.

Can refractory bricks be used in pyrolysis plants?

Yes, refractory bricks can be used in pyrolysis plants. Refractory bricks are designed to withstand high temperatures and are resistant to thermal stress and chemical corrosion. In pyrolysis plants, where organic materials are heated to very high temperatures in the absence of oxygen to produce useful products, refractory bricks can be used to line the furnace, reactor, and other high-temperature areas to ensure the structural integrity and longevity of the plant.

What is the porosity of refractory bricks?

The porosity of refractory bricks refers to the extent to which they contain open spaces or pores. These pores allow for the absorption and release of gases, liquids, or heat within the bricks. The porosity of refractory bricks is typically kept low to prevent the penetration of molten materials during high-temperature applications, ensuring their durability and resistance to thermal shock.

Wholesale Refractory Bricks from supplier in Dominica

Our team of experts can help you select the right Refractory Bricks for your specific requirements, ensuring optimal performance and durability. We offer competitive pricing and prompt delivery to ensure your projects stay on schedule. Additionally, our technical support team is available to provide guidance and assistance throughout the entire process, from product selection to installation. With our comprehensive services and experience, we are committed to being your trusted partner for all your Refractory Bricks needs in Dominica. Contact us today for more information or to request a quotation.

Hot Search

- Monolithic Refractories in British

- Ceramic Fiber Products in Paraguay

- Refractory Bricks in Dominica

- Raw Materials For Refractory in Malaysia

- Monolithic Refractories in Egypt

- Ceramic Fiber Products in Monaco

- Refractory Bricks in Grenada

- Refractory Bricks in Bolivia

- Ceramic Fiber Products in Andorra

- Ceramic Fiber Products in Indonesia