All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

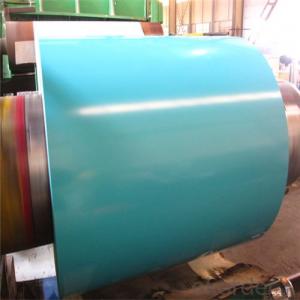

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel coils used in the aerospace industry for the fabrication of aircraft engine components and structural members?

Steel coils are used in the aerospace industry for the fabrication of aircraft engine components and structural members by being processed and formed into various shapes and sizes. These coils are typically made of high-strength steel alloys that offer excellent mechanical properties and durability. They are used to manufacture critical engine components such as turbine blades, compressor discs, and shafts, as well as structural members like wing spars and landing gear components. Through precision cutting, shaping, and heat treatment, steel coils are transformed into the necessary parts that provide strength, reliability, and performance to aircraft engines and structural systems.

How are steel coils used in the renewable energy sector, such as wind turbine production?

Steel coils are used in the renewable energy sector, specifically in wind turbine production, for various purposes. They are primarily used to manufacture the tower structures of wind turbines, which provide the necessary support and stability to the turbine. Additionally, steel coils are used in the production of turbine blades, which require a strong and durable material to withstand the harsh environmental conditions and generate energy efficiently. Overall, steel coils play a crucial role in the construction and functioning of wind turbines in the renewable energy sector.

What is the impact of coil crossbow on processing?

The impact of a coil crossbow on processing is that it can significantly enhance the efficiency and speed of various tasks. With its powerful and precise shooting mechanism, a coil crossbow can quickly and accurately complete processes such as target shooting, hunting, or even industrial applications like cutting or drilling. Its compact size and lightweight design also make it portable and easy to maneuver, further improving processing capabilities in different environments.

Wholesale Steel Coils from supplier in Chile

Whether you are in the construction, manufacturing, or automotive industry, our Steel Coils are designed to meet your specific requirements. We offer a wide range of steel grades, thicknesses, and widths to suit various applications. Our Steel Coils are manufactured using high-quality materials and advanced technology, ensuring durability and reliability.

In addition to supplying Steel Coils, we also provide value-added services such as cutting, slitting, and coating. Our cutting-edge facilities and skilled workforce enable us to tailor our products to your exact specifications, saving you time and money.

At CNBM, we understand the importance of timely delivery and efficient logistics. With our vast network and strategic partnerships, we can ensure that your Steel Coils are delivered to your doorstep in a timely and cost-effective manner.

Furthermore, our commitment to sustainability and environmental responsibility sets us apart. We adhere to strict quality control measures and comply with international standards to ensure that our Steel Coils meet the highest industry standards. Additionally, we actively promote recycling and resource conservation throughout our operations.

Partnering with us means gaining a reliable and trusted supplier for all your Steel Coils needs in Chile. Our dedicated team of professionals is ready to assist you throughout the entire procurement process, from product selection to after-sales support. Contact us today to discuss your Steel Coils requirements and experience the CNBM difference.

In addition to supplying Steel Coils, we also provide value-added services such as cutting, slitting, and coating. Our cutting-edge facilities and skilled workforce enable us to tailor our products to your exact specifications, saving you time and money.

At CNBM, we understand the importance of timely delivery and efficient logistics. With our vast network and strategic partnerships, we can ensure that your Steel Coils are delivered to your doorstep in a timely and cost-effective manner.

Furthermore, our commitment to sustainability and environmental responsibility sets us apart. We adhere to strict quality control measures and comply with international standards to ensure that our Steel Coils meet the highest industry standards. Additionally, we actively promote recycling and resource conservation throughout our operations.

Partnering with us means gaining a reliable and trusted supplier for all your Steel Coils needs in Chile. Our dedicated team of professionals is ready to assist you throughout the entire procurement process, from product selection to after-sales support. Contact us today to discuss your Steel Coils requirements and experience the CNBM difference.