All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do geomembranes contribute to the remediation of polluted water bodies?

Geomembranes contribute to the remediation of polluted water bodies by acting as a barrier to prevent the contamination from spreading further. They are used to line ponds, lakes, and reservoirs, effectively sealing off the polluted water and preventing the pollutants from leaching into the surrounding soil and groundwater. Additionally, geomembranes can be used in the construction of containment cells or landfills to safely store and isolate the contaminated sediments or waste materials, minimizing the risk of further pollution.

How do geomembranes prevent leaks in nuclear waste storage facilities?

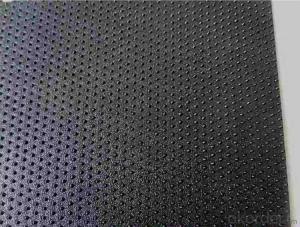

Geomembranes prevent leaks in nuclear waste storage facilities by acting as a barrier between the waste and the surrounding environment. These specially engineered membranes are made of durable materials, such as high-density polyethylene or polyvinyl chloride, which have excellent resistance to chemicals and punctures. They are installed as lining systems in the storage facility, creating a impermeable layer that prevents any leakage or seepage of the hazardous waste into the soil or groundwater. Additionally, geomembranes are designed to withstand harsh environmental conditions, including extreme temperatures and UV radiation, ensuring long-term integrity and reliable containment of the nuclear waste.

Are geomembranes resistant to freeze-thaw cycles?

Yes, geomembranes are generally resistant to freeze-thaw cycles. They are designed to withstand extreme temperature variations without undergoing significant physical or chemical changes. This resistance is due to their composition and material properties, which prevent them from cracking, breaking, or degrading when exposed to freezing and thawing conditions.

What are the different methods of geomembrane installation?

There are several methods of geomembrane installation, including loose-laid, anchored, and adhesive methods. In the loose-laid method, the geomembrane is simply placed on the prepared subgrade without any form of attachment. The anchored method involves securing the geomembrane to the subgrade using mechanical anchors or ballast materials. Adhesive installation, on the other hand, utilizes specialized adhesives to bond the geomembrane to the subgrade or adjacent materials. Each method is chosen based on the specific project requirements and site conditions.

Wholesale Geomembranes from supplier in Burundi

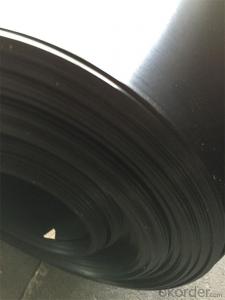

Our team of experts is dedicated to delivering high-quality Geomembranes that meet international standards. We understand the importance of reliable and durable solutions for various applications such as landfill liners, reservoir liners, mining containment, and agricultural water storage.

With our wide network of suppliers, we can offer competitive prices and ensure timely delivery of your orders. Our sales team is available to assist you with product selection and provide customized solutions based on your specific needs. We also offer technical support services to help you with installation, maintenance, and troubleshooting.

At CNBM, we prioritize customer satisfaction and strive to build long-term partnerships with our clients. Our commitment to excellence and continuous improvement has made us a trusted supplier in the industry. Whether you are a contractor, engineer, or project manager, we are here to support you at every step of your project.

Contact us today to discuss your Geomembranes requirements in Burundi and let us be your reliable partner in procurement.

With our wide network of suppliers, we can offer competitive prices and ensure timely delivery of your orders. Our sales team is available to assist you with product selection and provide customized solutions based on your specific needs. We also offer technical support services to help you with installation, maintenance, and troubleshooting.

At CNBM, we prioritize customer satisfaction and strive to build long-term partnerships with our clients. Our commitment to excellence and continuous improvement has made us a trusted supplier in the industry. Whether you are a contractor, engineer, or project manager, we are here to support you at every step of your project.

Contact us today to discuss your Geomembranes requirements in Burundi and let us be your reliable partner in procurement.