All Categories

- - Steel Wire Rod

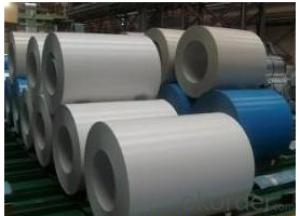

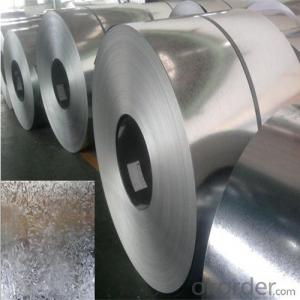

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What role does coil packaging and banding play in the secure transportation of steel coils?

Coil packaging and banding play a crucial role in ensuring the secure transportation of steel coils. By securely packaging and banding the coils, the risk of damage during transit is significantly reduced. This packaging method helps to prevent shifting, tangling, or falling of the coils, thereby minimizing the potential for accidents or injuries. Additionally, the bands provide added stability and support, preventing any potential damage to the coils caused by external factors such as vibrations or rough handling. Ultimately, coil packaging and banding play a vital role in maintaining the integrity and safety of steel coils during transportation.

What is the impact of coil memory on the performance of wire drawing and cable manufacturing?

Coil memory refers to the tendency of a wire or cable to retain its coiled shape even after being straightened. This characteristic can significantly impact the performance of wire drawing and cable manufacturing processes.

When wire with high coil memory is used in these processes, it can result in various challenges. Firstly, the wire may resist straightening, making it difficult to achieve the desired length and shape of the product. This can lead to inefficiencies and increased production time.

Moreover, the coil memory can cause uneven tension distribution during wire drawing or cable manufacturing. This can result in inconsistencies in the final product, leading to potential quality issues. Additionally, the wire may have a higher risk of tangling, knotting, or kinking during these processes, further affecting the overall performance and reliability of the manufactured cables.

Therefore, managing coil memory is crucial in wire drawing and cable manufacturing. Techniques such as annealing or using materials with lower coil memory can be employed to reduce the impact and ensure optimal performance and quality of the final products.

What is the impact of coil defects on the manufacturing of consumer goods?

Coil defects in manufacturing can have significant impacts on the production of consumer goods. These defects can lead to product failures, quality issues, and increased manufacturing costs. Defective coils may result in malfunctioning or unreliable products, which can damage a company's reputation and lead to customer dissatisfaction. Additionally, addressing and rectifying these defects can require additional time, effort, and resources, ultimately affecting the overall manufacturing process and profitability. Therefore, it is crucial for manufacturers to implement stringent quality control measures to identify and rectify coil defects to ensure the production of high-quality consumer goods.

Wholesale Steel Coils from supplier in Belarus

Our team of highly experienced professionals is dedicated to providing personalized solutions tailored to your specific needs. Whether you require steel coils for construction, automotive, or other industrial applications, we have the expertise to guide you towards the most suitable products.

In addition to our wide product range, we also offer competitive pricing and efficient logistics services to ensure timely delivery of your orders. Our strong relationships with top manufacturers enable us to source high-quality steel coils at competitive prices, passing on the cost savings to our customers.

Furthermore, our technical support team is always available to assist you with any inquiries or concerns you may have. We understand the importance of prompt and accurate information, and we strive to provide the best possible customer service.

At our company, we believe in building long-term partnerships with our clients based on trust, reliability, and mutual success. We are committed to exceeding your expectations and providing you with the highest level of service in the industry.

Thank you for choosing our company as your supplier of steel coils in Belarus. We look forward to serving you and contributing to the success of your projects.

In addition to our wide product range, we also offer competitive pricing and efficient logistics services to ensure timely delivery of your orders. Our strong relationships with top manufacturers enable us to source high-quality steel coils at competitive prices, passing on the cost savings to our customers.

Furthermore, our technical support team is always available to assist you with any inquiries or concerns you may have. We understand the importance of prompt and accurate information, and we strive to provide the best possible customer service.

At our company, we believe in building long-term partnerships with our clients based on trust, reliability, and mutual success. We are committed to exceeding your expectations and providing you with the highest level of service in the industry.

Thank you for choosing our company as your supplier of steel coils in Belarus. We look forward to serving you and contributing to the success of your projects.