All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

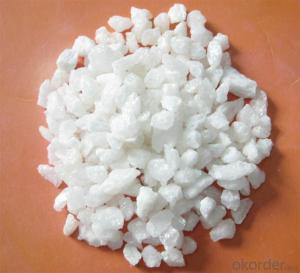

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can you discuss the properties and applications of vermiculite in lightweight refractories?

Vermiculite is a natural mineral with unique properties that make it suitable for various applications in lightweight refractories. It has a layered structure that allows it to expand when heated, resulting in increased volume and improved insulation properties.

One of the key properties of vermiculite is its excellent thermal resistance, which makes it an ideal material for insulating refractories. It has a low thermal conductivity, meaning it can effectively reduce heat transfer and improve energy efficiency in high-temperature environments.

Additionally, vermiculite has good chemical stability, making it resistant to many corrosive substances and maintaining its integrity under harsh conditions. This property is essential in refractory applications where the material comes into contact with aggressive chemicals or gases.

Another advantage of vermiculite is its lightweight nature. Due to its low density, it can significantly reduce the weight of refractory structures, making them easier to handle and install. This property is particularly beneficial in applications where weight reduction is critical, such as in aerospace or automotive industries.

In terms of applications, vermiculite is commonly used in lightweight refractories for insulation purposes. It is often incorporated into castables, bricks, and boards to enhance their thermal efficiency and reduce heat loss. Additionally, vermiculite can be utilized in the manufacturing of refractory coatings and linings to provide insulation and protection against thermal shock.

Overall, vermiculite's unique properties, including thermal resistance, chemical stability, and lightweight nature, make it a valuable component in lightweight refractories, improving insulation efficiency and offering protection in various high-temperature applications.

What is the role of boron carbide in refractory materials?

Boron carbide plays a crucial role in refractory materials as it helps enhance their thermal stability and resistance to high temperatures. It acts as a strong ceramic binder, providing strength and structural integrity to refractory products. Additionally, boron carbide's exceptional hardness and abrasion resistance contribute to the durability and longevity of refractory materials, making them suitable for applications in high-temperature environments such as kilns, furnaces, and metal processing industries.

What are the properties of chromite-based refractory materials?

Chromite-based refractory materials have excellent thermal stability, high resistance to corrosion, and good mechanical strength. They also have a high melting point, low thermal expansion coefficient, and good resistance to thermal shock. Additionally, chromite-based refractories exhibit good chemical inertness, making them ideal for use in high-temperature applications such as furnaces and kilns.

Which refractory raw materials are commonly used in the chemical industry?

Some commonly used refractory raw materials in the chemical industry include alumina, silica, magnesia, zirconia, and chrome ore. These materials have high melting points and excellent resistance to heat, corrosion, and chemical reactions, making them suitable for lining furnaces, reactors, and other equipment used in chemical processes.

Wholesale Raw Materials For Refractory from supplier in Afghanistan

We understand the importance of high-quality raw materials for refractory applications, and we are committed to delivering products that meet the highest industry standards. Our team of experts is well-versed in the technical specifications and requirements of different industries, ensuring that we can provide tailored solutions to meet your specific needs.

In addition to supplying raw materials, we also offer sales and quotation services to ensure a seamless procurement process. Our team will work closely with you to understand your requirements and provide competitive pricing options. We believe in building long-term relationships with our clients, and our dedicated sales team is always available to address any queries or concerns you may have.

Furthermore, we provide technical support services to assist you throughout the entire project lifecycle. Our technical experts can offer guidance on material selection, application techniques, and troubleshooting, ensuring that you achieve optimal results. We understand that each project is unique, and we are committed to providing personalized support to help you overcome any challenges you may face.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to offer comprehensive procurement services, ensuring that you have access to a wide range of raw materials for refractory applications. We are dedicated to sourcing high-quality products and ensuring timely delivery to meet your project timelines.

Our experience in the Afghan market sets us apart from our competitors. We understand the local industry landscape, regulations, and challenges, allowing us to provide valuable insights and expertise to enhance the success of your projects. We believe in fostering strong partnerships with our clients, and we are committed to delivering exceptional service and support.

If you are looking for a reputable supplier of raw materials for refractory in Afghanistan, we are ready to meet your needs. Contact us today to discuss your requirements and let us be your trusted partner in achieving success.

In addition to supplying raw materials, we also offer sales and quotation services to ensure a seamless procurement process. Our team will work closely with you to understand your requirements and provide competitive pricing options. We believe in building long-term relationships with our clients, and our dedicated sales team is always available to address any queries or concerns you may have.

Furthermore, we provide technical support services to assist you throughout the entire project lifecycle. Our technical experts can offer guidance on material selection, application techniques, and troubleshooting, ensuring that you achieve optimal results. We understand that each project is unique, and we are committed to providing personalized support to help you overcome any challenges you may face.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to offer comprehensive procurement services, ensuring that you have access to a wide range of raw materials for refractory applications. We are dedicated to sourcing high-quality products and ensuring timely delivery to meet your project timelines.

Our experience in the Afghan market sets us apart from our competitors. We understand the local industry landscape, regulations, and challenges, allowing us to provide valuable insights and expertise to enhance the success of your projects. We believe in fostering strong partnerships with our clients, and we are committed to delivering exceptional service and support.

If you are looking for a reputable supplier of raw materials for refractory in Afghanistan, we are ready to meet your needs. Contact us today to discuss your requirements and let us be your trusted partner in achieving success.

Hot Search

- Monolithic Refractories in Cameroon

- Ceramic Fiber Products in Slovakia

- Refractory Bricks in Guyana

- Raw Materials For Refractory in Azerbaijan

- Refractory Bricks in Guinea

- Refractory Bricks in Turkmenistan

- Raw Materials For Refractory in Egypt

- Ceramic Fiber Products in Thailand

- Refractory Bricks in Belarus

- Refractory Bricks in South Africa