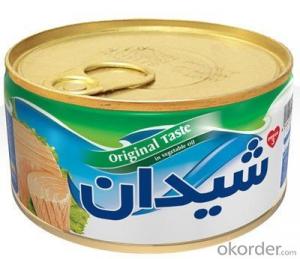

Tinplate Can

Tinplate Can Related Searches

Tinplate Printing Machine Tinplate Iron Tinplate Material Mth Standard Gauge Tinplate Tinplate Fire Engine Mth Tinplate Set Tinplate Model Trains Lionel Tinplate Blue Comet Tinplate Coating Mth Tinplate ChristmasHot Searches

Tinplate China Tinplate Stock Price Tata Tinplate Price List Tinplate Price Trend Tinplate Nse Share Price Tinplate Price Chart Tinplate Share Price Nse Tata Tinplate Share Price Tinplate Share Price Today Tinplate Share Price Bse Tinplate Price Tinplate Share Price Tinplate Coil Manufacturers Tinplate Sheet Suppliers Food Mixer Sale Tinplate Factory Tinplate Production Tinplate Products Ltd Tinplate Products Tinplate Can ManufacturersTinplate Can Supplier & Manufacturer from China

Okorder.com is a professional Tinplate Can supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Tinplate Can firm in China.Hot Products

FAQ

- The common surface treatments for tinplate include electrolytic tin plating, chrome plating, and lacquering.

- Yes, tinplate can be used for packaging products with specific storage requirements. Tinplate is known for its excellent protective properties, including resistance to moisture, oxygen, and light, which makes it suitable for preserving the quality and freshness of various products. Additionally, tinplate is highly durable and can withstand temperature variations, making it ideal for packaging products with specific storage needs.

- Tinplate enhances the tamper-evident features of a product by providing a secure and durable packaging solution. Its unique properties, such as strength, rigidity, and resistance to corrosion, make it difficult for tampering attempts to go unnoticed. Additionally, tinplate can be easily sealed, ensuring that any unauthorized access or tampering is immediately visible to consumers.

- Tinplate packaging contributes to product ease of use by providing a sturdy and durable material that is easy to open, close, and handle. Its smooth surface allows for effortless stacking and storage, while its lightweight nature makes it convenient to carry. Additionally, tinplate packaging often incorporates user-friendly features such as easy-to-grip lids and pull-tabs, enhancing the overall user experience.

- Yes, tinplate can be used for luxury packaging. Tinplate is a versatile material that offers a high level of durability, strength, and visual appeal. It can be molded into various shapes and sizes, making it suitable for creating luxurious and exquisite packaging designs. Additionally, tinplate has a premium appearance and can be decorated with intricate designs or embossing, enhancing the overall aesthetic of luxury packaging.

- Yes, tinplate can be used for packaging liquid products. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent barrier properties against moisture and oxygen. This makes it suitable for packaging liquids as it helps to prevent spoilage and maintain the product's quality. Additionally, tinplate is also durable and safe for food contact, making it a popular choice for packaging various liquid products such as beverages, oils, and sauces.

- Tinplate is widely used in the electrical industry for various applications such as the production of electrical enclosures, transformer tanks, and terminal boxes. Its corrosion-resistant properties make it an ideal material choice to protect electrical components from moisture and other environmental factors. Additionally, tinplate is used for manufacturing electrical connectors, terminals, and busbars due to its excellent electrical conductivity.

- Tinplate is coated with food-grade materials through a process called electrolytic tinplating. In this process, a thin layer of tin is electroplated onto the surface of the tinplate to provide a protective coating. This coating ensures that the tinplate is safe for direct contact with food and prevents any reaction between the metal and the food, thereby maintaining the food's quality and safety.