Electrical Tinplate, JIS G3303 Standard For Food Cans & Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter.

It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

TINPLATE SPECIFICATION

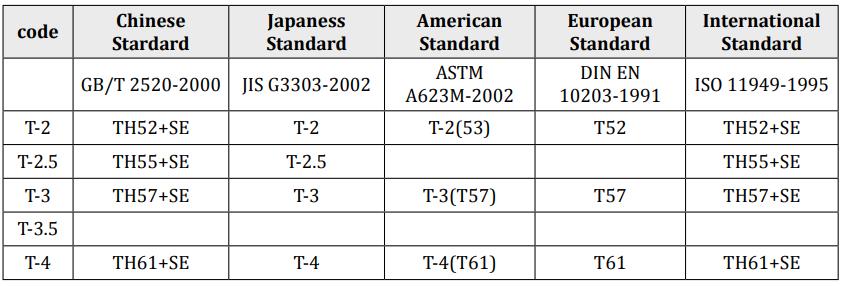

1.Reference standard: GB/T 2520-2000,JIS G3303-2002 and DIN EN 10203-1991

2. Raw material: MR and SPCC

3.Thickness: 0.13 to 0.5mm

4.Width: 600-1050mm

5.Coil diameter: ID 420mm or 508mm

6.Temper: T1~T5,DR8~DR10

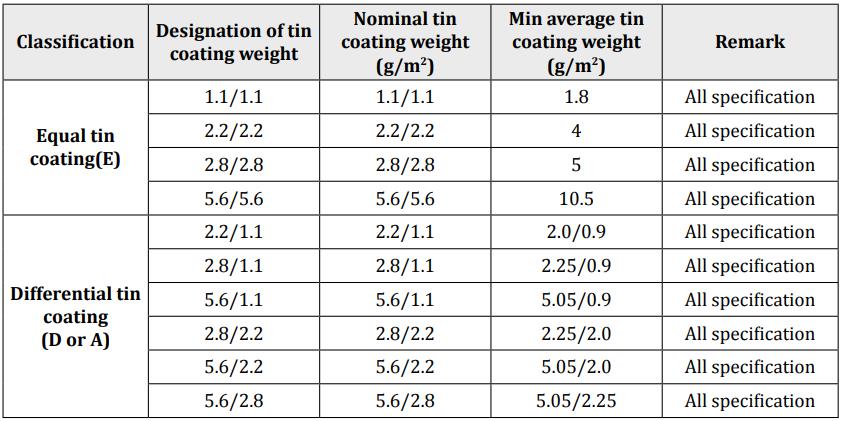

7.Tin coating: 1.1g~11.2g, We can produce according to customer's requests.

8. Applications: paint, chemical and other usage can make battery, electric cable and other industries

9. Package: anti-rust paper, corner protected. Sheets or coils according customer's requests

STANDARD

SURFACE

| Marks | Surface state | Characteristics |

| B | Bright rough | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip featuring certain oriented rubstone figure. |

| RR | St hStone rough | Glazed surface obtained after melting treatment of electrotinned raw material strip featuringg p g certain oriented rubstone figure. |

| S | Silver rough | Glazed surface obtained after melting treatment of electrotinned raw material strip with rough matt surface. |

COATING

APPLICATION

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Q:What are the common defects found in tinplate packaging?

- Common defects found in tinplate packaging include: 1. Corrosion: Tinplate can be prone to corrosion, resulting in rust spots or holes in the packaging. This can compromise the integrity of the packaging and affect the quality and safety of the product inside. 2. Dents and scratches: During handling or transportation, tinplate packaging can get dented or scratched. These defects can be purely cosmetic, but in some cases, they may lead to leaks or damage to the product. 3. Poor sealing: Improper sealing of tinplate packaging can lead to leaks or contamination of the product. This can occur due to faulty machinery or inadequate quality control during the packaging process. 4. Print defects: Tinplate packaging often includes printed information or branding. Common defects in this area include misalignment, smudging, fading, or incomplete printing. These defects can affect the visual appeal of the packaging and the overall product presentation. 5. Manufacturing defects: Tinplate packaging can sometimes have manufacturing defects such as uneven edges, poor welds, or misaligned seams. These defects may weaken the packaging structure or cause sharp edges that could potentially harm consumers. It is important for manufacturers to have strict quality control measures in place to identify and rectify these defects, ensuring the safety, functionality, and aesthetics of tinplate packaging.

- Q:How does tinplate compare to aluminum in terms of properties and applications?

- Tinplate and aluminum have distinct properties and applications. Tinplate is a steel sheet coated with a thin layer of tin, making it corrosion-resistant and suitable for packaging cans, containers, and other food-grade products. On the other hand, aluminum is a lightweight and highly malleable metal with excellent corrosion resistance, making it ideal for various applications like aerospace, construction, and electrical conductors. While both materials have their unique advantages, the choice between tinplate and aluminum depends on the specific requirements and intended use of the product.

- Q:What are the advantages of using tinplate for packaging?

- Tinplate offers several advantages for packaging. Firstly, it provides excellent protection against moisture, air, light, and other external factors that could potentially damage the packaged goods. This ensures the preservation of quality and extends the shelf life of products. Secondly, tinplate is highly durable and resistant to corrosion, making it ideal for long-term storage and transportation. Additionally, tinplate is easily recyclable, making it an environmentally friendly choice. Lastly, tinplate provides a versatile and attractive packaging option, as it can be easily shaped and decorated, enhancing the visual appeal of the product.

- Q:How does tinplate packaging handle exposure to different chemicals?

- Tinplate packaging is highly resistant to exposure to different chemicals, making it a reliable choice for packaging various products. Its non-reactive nature ensures that it does not contaminate or react with the contents inside, maintaining the product's quality and safety. Additionally, tinplate packaging is often coated with a protective layer, such as lacquer or enamel, further enhancing its resistance to chemical exposure. Overall, tinplate packaging proves to be a durable and dependable option when it comes to handling different chemicals.

- Q:What are the industry standards for tinplate?

- The industry standards for tinplate typically include specifications regarding the tin coating thickness, base metal quality, surface finish, dimensional tolerances, and other relevant characteristics. These standards are established by organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM), ensuring consistency and quality across the tinplate industry.

- Q:How big is the difference between tinplate and stainless steel 316L?

- 316L is a kind of austenitic stainless steel with excellent corrosion resistance. The tinplate is not comparable. 316L is superior to tinplate in appearance, corrosion resistance, heat resistance and strength. Of course, the price is much higher than that of tinplate.

- Q:How is tinplate coated for pharmaceutical packaging?

- Tinplate is coated for pharmaceutical packaging by applying a thin layer of protective lacquer or enamel onto the surface. This coating acts as a barrier, preventing direct contact between the metal and the pharmaceutical product, ensuring its safety and integrity.

- Q:What are the main applications of tinplate in the electrical industry?

- Tinplate is widely used in the electrical industry for various applications such as manufacturing of electrical enclosures, switchgear cabinets, and transformer cores. Its corrosion-resistant properties make it an ideal material for protecting electrical components from environmental factors. Additionally, tinplate is often utilized for the production of electrical connectors and terminals due to its excellent conductivity and solderability.

- Q:What are the common sizes of tinplate sheets?

- The common sizes of tinplate sheets vary, but they generally come in standard dimensions such as 24 x 36 inches, 36 x 48 inches, and 48 x 96 inches.

- Q:How does tinplate perform in terms of UV resistance?

- Tinplate generally has poor UV resistance, meaning it is not highly resistant to the damaging effects of ultraviolet radiation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrical Tinplate, JIS G3303 Standard For Food Cans & Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords