Stratagrid Geogrid

Stratagrid Geogrid Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleStratagrid Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Stratagrid Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stratagrid Geogrid firm in China.Hot Products

FAQ

- Polyester warp knitted polyester geogrid and glass fiber geogrid price difference in the price of many components is a ghost?

- Polyester warp knitted polyester coating is PVC glue, glass fiber geogrid is that sensitive asphalt rubber. An anti-corrosion, a alkali resistance. Material is not the same, the appearance is not difficult to distinguish between experts

- Geogrids offer several advantages in ground reinforcement, such as increased stability and load-bearing capacity. They distribute the load more evenly, reducing the risk of soil erosion and settlement. Geogrids also improve soil confinement, preventing lateral movement and promoting better compaction. They are versatile, cost-effective, and easy to install, making them a preferred choice for various applications like road construction, retaining walls, and slope stabilization.

- The future of geotechnical materials

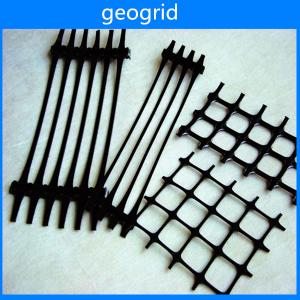

- Polyester geogridPolyester fiber warp knitted geogrid with high strength polyester fiber as raw material. The warp oriented structure, fabric of warp yarn between the bending state, cross point binding combined with high-strength fiber filament, forming strong junctions, give full play to the mechanical properties of high strength polyester fiber warp knitting geogrid has high tensile strength, elongation force, tearing strength, and strength the difference is small, the UV aging resistance, abrasion resistance, corrosion resistance, light weight, and soil or gravel interlocking force, to enhance soil shearing strength and improve the integrity and bearing capacity of the soil has a significant effect.

- What are the two levels of widening of the geogrid in the asphalt concrete road?

- If it is other material should be placed in the ground inside, thank you.

- Geocell of earthwork grid construction method

- Engineering application of geocell1, deal with half fill roadbedOn the ground of natural slope in 1:5 acts on the slope of embankment, embankment should be dug in steps, step width not less than 1M when the stage of building or rebuilding highway widening, convergence of old and new subgrade embankment slope, excavation step should be of high grade highway, the step width is 2M, the laying of geocell in each layer step on a horizontal plane, using geocell own facade side limit reinforcement effect, the problem of uneven subsidence of a better solution.2, sandy area roadbedSandy area on the low embankment subgrade, filling height is generally not less than 0.3M. due to the Low Subgrade Construction of sandy area and heavy bearing professional requirements, the geocell can play on the loose packing lateral confinement effect, with high stiffness and strength in the limited height of subgrade protection, to load large vehicle stress.3, the back embankment fillThe geocell reinforced abutment can achieve the purpose of better, geocell and fillers can generate enough friction, effectively reduce the roadbed and structures between uneven settlement, can effectively alleviate the "final abutment jump" disease of the early impact damage of bridge deck.

- The typical weight of a geogrid roll can vary depending on the specific type and size of the geogrid. However, geogrid rolls generally range in weight from 50 to 500 pounds.

- There are several types of geogrids available, including uniaxial geogrids, biaxial geogrids, and triaxial geogrids. Uniaxial geogrids primarily provide strength in one direction, typically used for soil stabilization and reinforcement. Biaxial geogrids offer strength in both directions, commonly used for soil stabilization, retaining walls, and road construction. Triaxial geogrids provide strength in all three directions, ideal for reinforcement in heavy-duty applications like railway tracks and airport runways.