Stainless Steel Wire Shelving

Stainless Steel Wire Shelving Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleStainless Steel Wire Shelving Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Wire Shelving supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Wire Shelving firm in China.Hot Products

FAQ

- There are several weaving patterns available for stainless steel wire mesh, including plain weave, twill weave, Dutch weave, and reverse Dutch weave. These patterns vary in terms of wire density, mesh opening size, and strength, allowing for different applications and levels of filtration.

- There are several different types of stainless steel wire that are commonly used in heat exchangers. These include: 1. Austenitic stainless steel wire: This type of stainless steel is the most widely used in heat exchangers due to its excellent corrosion resistance and high temperature resistance. It contains high levels of chromium and nickel, which provide the material with its corrosion resistance properties. 2. Ferritic stainless steel wire: Ferritic stainless steel wire is another common choice for heat exchangers. It has a higher carbon content compared to austenitic stainless steel, which provides it with improved strength and heat resistance. However, it has lower corrosion resistance than austenitic stainless steel. 3. Duplex stainless steel wire: Duplex stainless steel wire is a combination of both austenitic and ferritic stainless steel, offering a balance between the two types. It provides good corrosion resistance and high strength, making it suitable for demanding heat exchanger applications. 4. Martensitic stainless steel wire: Martensitic stainless steel wire is known for its high strength and hardness. It is often used in heat exchangers that require excellent mechanical properties, but it has lower corrosion resistance compared to other stainless steel types. The choice of stainless steel wire for heat exchangers depends on various factors, including the operating environment, temperature, and specific requirements of the application. Each type of stainless steel wire has its own unique properties, allowing heat exchanger manufacturers to select the most appropriate material for their specific needs.

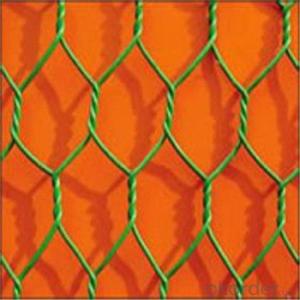

- There are various wire shapes available in stainless steel, including round wire, flat wire, square wire, and hexagonal wire.

- Yes, stainless steel wire can be used for sifting and sieving applications. Stainless steel wire is known for its durability, strength, and resistance to corrosion and high temperatures. These qualities make it an ideal material for sifting and sieving applications where reliability and longevity are important factors. Stainless steel wire meshes and screens can be used to separate particles of different sizes, ensuring accurate and efficient sieving. Additionally, the smooth surface of stainless steel wire prevents the accumulation of debris and facilitates easy cleaning, making it a hygienic choice for food and pharmaceutical industries. Overall, stainless steel wire is widely used in various industries for sifting and sieving applications due to its excellent mechanical properties and resistance to wear and tear.

- The conductivity of stainless steel wire is relatively low compared to other metals, such as copper or aluminum.

- Yes, stainless steel wire can indeed be used in food processing industries. Stainless steel is a popular material choice in industries that require strict hygiene standards, such as the food processing industry, due to its corrosion resistance, durability, and ease of cleaning. Stainless steel wire is commonly used for various applications in food processing, including conveyor belts, screens, sieves, and mesh baskets. It is also used for parts and components of food processing equipment, such as mixers, pumps, and cutting machines. Stainless steel wire's resistance to corrosion, high temperatures, and chemicals makes it an ideal choice for ensuring food safety and maintaining high standards of cleanliness in food processing facilities.

- Which is better, such as stainless steel wire drawing board and rose gold drawing board, such as moisture-proof effect, abrasion resistance and so on?

- Stainless steel surface is like filamentous texture, this is only a stainless steel processing technology. The surface is Matt, and carefully look at the above there is a trace of texture, but can not touch it.