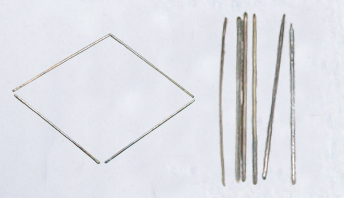

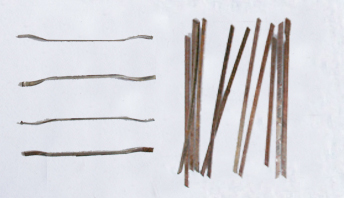

Heat-resistant stainless steel fibers melt pumping

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Fiber Grade:

The grades of steel fiber should be suitably selected based on the temperature and atmosphere.

Physical, Mechanical and corrosion resistant properties of stainless steel fiber

| 304 | 310 | 330 | 446 | 430 |

Melting Point Range ℃ | 1400-1425 | 1400-1450 | 1400-1425 | 1425-1510 | 1425-1510 |

Elastic modulus at 870℃ | 12.66 | 12.66 | 13.71 | 9.84 | 8.44 |

Tensile strength at 870℃ | 127 | 155 | 197 | 54 | 48 |

Thermal expansion coefficient at | 20.16 | 18.58 | 17.64 | 13.14 | 13.68 |

Heat conductance at 500℃ | 21.5 | 18.7 | 21.6 | 24.4 | 26.3 |

Specific gravity at romm temperature, g/cm³ | 8.0 | 8.0 | 8.0 | 7.5 | 7.8 |

Loss of weight (%) after 1000 hours of circulating oxidization at 982℃(%) | 70(100h) | 13 | 18 | 4 | 70(100h) |

*Violent circulating state in air | 870 | 1035 | 1035 | 1175 | 870 |

982 | 1050 | 1150 | 1095 | 815 | |

Corrosion in H2S,Mil/yr | 200 | 100 | / | 100 | 200 |

Recommended max operating temperature when it is used in SO2℃ | 800 | 1050 | / | 1025 | 800 |

Corrosion in natural gas at 815℃ |

| 3 |

| 4 | 12 |

Corrosion in coking coal gas at 982℃ | 225 | 25 | 75 | 14 | 236 |

Nitrogenization in anhydrous ammonia at 525℃ | 80 | 55 | 20 | 175 | <304# |

Corrosion by CH2 at 454℃, Mil/yr | 4.8 | 2.3 |

| 8.7 | 21.9 |

Carbon pick-up of alloy % with solids carbonized at 982℃ for 24 hours and 40 times of circulations, % | 1.40 | 0.02 | 0.08 | 0.07 | 1.03 |

- Q:Can stainless steel wire be used for filtration?

- Yes, stainless steel wire can be used for filtration. Stainless steel wire mesh is often used in filtration applications due to its durability, corrosion resistance, and ability to withstand high temperatures. The fine mesh structure of stainless steel wire allows it to effectively filter out particles of various sizes, making it suitable for a wide range of filtration processes. Additionally, stainless steel wire can be easily cleaned and reused, making it a cost-effective and sustainable choice for filtration applications.

- Q:What are the different wire forms available for stainless steel wire?

- There are several different wire forms available for stainless steel wire, including round wire, flat wire, square wire, and shaped wire. These wire forms are used for various applications such as springs, wire mesh, jewelry, and electrical components.

- Q:Can stainless steel wire be used for wire rope clamps?

- Indeed, wire rope clamps can utilize stainless steel wire as a reliable option. Due to its robustness and resistance to corrosion, stainless steel proves to be a fitting material for numerous purposes, including wire rope clamps. Wire rope clamps crafted from stainless steel frequently find their application in construction, marine, and agricultural industries, where a steadfast and trustworthy connection between wire ropes is imperative. Thanks to stainless steel's durability and ability to resist corrosion, these wire rope clamps can endure substantial loads and harsh surroundings without jeopardizing their integrity. Moreover, stainless steel's visual appeal contributes to its popularity in applications where aesthetics hold significance.

- Q:What are the different types of stainless steel wire used in heat exchangers?

- Heat exchangers commonly utilize various types of stainless steel wire. These include: 1. Austenitic stainless steel wire, which is widely used due to its exceptional corrosion resistance and high temperature resistance. Its corrosion resistant properties are attributed to its high chromium and nickel content. 2. Ferritic stainless steel wire, another popular option for heat exchangers, possesses increased strength and heat resistance due to its higher carbon content compared to austenitic stainless steel. However, it exhibits lower corrosion resistance. 3. Duplex stainless steel wire combines the qualities of both austenitic and ferritic stainless steel. It offers a balanced blend of corrosion resistance and high strength, making it suitable for demanding heat exchanger applications. 4. Martensitic stainless steel wire is renowned for its superior strength and hardness. It is commonly employed in heat exchangers that require exceptional mechanical properties, despite having lower corrosion resistance compared to other stainless steel types. The selection of stainless steel wire for heat exchangers relies on various factors, such as the operating environment, temperature, and specific application requirements. Each type of stainless steel wire possesses distinct properties, enabling heat exchanger manufacturers to choose the most appropriate material for their specific needs.

- Q:Can stainless steel wire be used for automotive springs?

- Automotive springs can indeed utilize stainless steel wire. Renowned for its exceptional strength, resistance to corrosion, and long-lasting nature, stainless steel proves to be a fitting material for a variety of applications, including automotive springs. These springs play a crucial role in absorbing shocks and providing support to a vehicle's suspension system. In comparison to other materials, stainless steel springs offer numerous advantages. They have an extended lifespan, require less maintenance, and enhance performance. Even when subjected to high temperatures, road salts, and moisture, these springs can endure without succumbing to rust or corrosion. They retain their shape and functionality even when under heavy loads and continuous use. Furthermore, customization is possible as stainless steel wire can be manufactured to meet specific strength and flexibility requirements, catering to the needs of individual vehicles. Overall, stainless steel wire is a dependable and widely favored choice for automotive springs due to its exceptional properties, which enhance vehicle performance and reliability.

- Q:Can stainless steel wire be used for wire sculpture?

- Yes, stainless steel wire can definitely be used for wire sculpture. Stainless steel wire is a popular choice among wire sculptors due to its durability, strength, and resistance to corrosion. It is a versatile material that can be easily shaped and manipulated into various forms and structures. Its smooth surface allows for easy bending, twisting, and coiling, making it ideal for creating intricate and detailed sculptures. Additionally, the metallic sheen of stainless steel wire adds a unique aesthetic appeal to the finished artwork. Overall, stainless steel wire is a great option for wire sculptors looking for a reliable and long-lasting material to bring their artistic visions to life.

- Q:What type of welding machine is needed for 0.3 mm thick stainless steel welding? Hand welding. Do you need a wire feeder?

- Stainless steel wire wire, one meter long, one like wire, as a bundle, according to their needs cut into the appropriate length.

- Q:Stainless steel 304 work teeth, easy to break the silk work?

- 304 stainless steel is a common stainless steel material, the density of 7.93 g/cm3, the industry is also called 18/8 stainless steel. High temperature resistance of 800 degrees, with good processability, high toughness characteristics, widely used in industry and furniture decoration industry and food and medical industry.

- Q:Can stainless steel wire be used for making jewelry clasps?

- Yes, stainless steel wire can be used for making jewelry clasps. It is a durable and corrosion-resistant material that provides strength and longevity to clasps, ensuring the jewelry stays secure.

- Q:Can stainless steel wire mesh be used for filtration?

- Yes, stainless steel wire mesh can be used for filtration. Stainless steel wire mesh is known for its durability, corrosion resistance, and high strength, making it an excellent choice for various filtration applications. The mesh structure allows for the passage of fluids or gases while retaining solid particles or contaminants. It is commonly used in industries such as food and beverage, pharmaceuticals, oil and gas, water treatment, and many others. Stainless steel wire mesh can be fabricated into different forms, such as screens, discs, cylinders, or cartridges, to suit specific filtration requirements. It offers excellent filtration efficiency, reliability, and longevity, making it a popular choice for filtration purposes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat-resistant stainless steel fibers melt pumping

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords