Mirafi 3xt Geogrid

Mirafi 3xt Geogrid Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleMirafi 3xt Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Mirafi 3xt Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Mirafi 3xt Geogrid firm in China.Hot Products

FAQ

- Geogrids help in reducing construction equipment requirements by providing soil stabilization and reinforcement. They act as a support structure, distributing loads and reducing the need for heavy machinery. This allows for cost-effective and efficient construction, minimizing the requirement for extensive equipment usage.

- Yes, geogrids are suitable for use in reinforced retaining walls. Geogrids provide effective reinforcement by improving soil stability, preventing wall failure, and increasing overall structural integrity of the retaining wall. They enhance the load-bearing capacity of the wall and help distribute the forces exerted by the retained soil, making it a reliable and durable solution for reinforced retaining walls.

- There are several factors that can affect the installation time of geogrids. First and foremost, the size and complexity of the project play a significant role. Larger and more complex projects may require more time for planning, preparation, and execution. The type and condition of the soil also impact installation time. Soft or loose soils may require additional stabilization measures before the geogrids can be installed, which can extend the overall installation duration. Similarly, rocky or hard soils may require specialized equipment or techniques, which can also increase the installation time. The availability and accessibility of the site can also affect installation time. If the site is difficult to reach or has limited space for equipment and materials, it can slow down the installation process. Additionally, factors such as weather conditions, environmental restrictions, and safety considerations can further influence the installation time. Lastly, the experience and expertise of the installation team can greatly impact the efficiency and speed of the installation process. A skilled and experienced team can streamline the installation and overcome any challenges more effectively, reducing the overall installation time.

- What is the meaning of reinforced subgrade? Is there a geogrid type on the road?

- Some of them may be designed to be made of geocell and geotechnical net. Mainly depends on how you design.

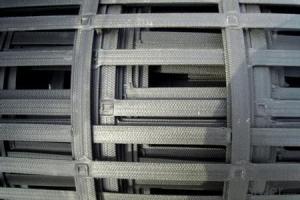

- Geogrids are known for their high durability characteristics. They are typically designed to withstand heavy loads, harsh environmental conditions, and long-term exposure to various elements. Geogrids are made from strong materials such as polyester or polypropylene, which provide excellent tensile strength and resistance against stretching or deformation. Additionally, they have good chemical resistance, making them suitable for use in different soil types and corrosive environments. Overall, geogrids offer long-lasting performance and can provide reliable reinforcement and stabilization for various civil engineering applications.

- Yes, geogrids can be used in bridge abutments and approach embankments. Geogrids are often employed in these structures to enhance soil stability, reinforce the embankment, and provide additional support to the bridge. By distributing loads more evenly and reducing lateral movement, geogrids can help improve the overall performance and longevity of the abutments and embankments.

- The installation of geogrids is typically carried out by first preparing the subgrade, which involves clearing the area of any debris and ensuring a stable foundation. Then, the geogrid material is rolled out and placed on top of the subgrade. It is important to align the geogrid properly and ensure that it is not wrinkled or damaged during installation. Anchoring devices, such as spikes or staples, are then used to secure the geogrid to the subgrade. Finally, the geogrid is covered with the desired fill material, such as soil or aggregate, to complete the installation process.

- Yes, geogrids are suitable for reinforcement of soft subgrades. Geogrids have been proven to effectively improve stability and strength in soft subgrade soils by distributing loads and reducing settlement. They provide additional tensile strength, preventing excessive deformation and enhancing the overall performance of the subgrade.