Geogrid Rolls

Geogrid Rolls Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleGeogrid Rolls Supplier & Manufacturer from China

Okorder.com is a professional Geogrid Rolls supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geogrid Rolls firm in China.Hot Products

FAQ

- Yes, geogrids are suitable for use in mining tailings dams. They are commonly used in such applications due to their high tensile strength, durability, and ability to reinforce soil and prevent erosion. Geogrids can enhance the stability and overall performance of tailings dams by providing structural support and preventing potential failures.

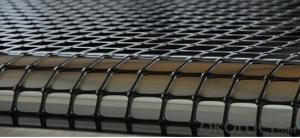

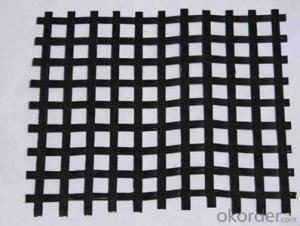

- There are several types of geogrids, including uniaxial geogrids, biaxial geogrids, and triaxial geogrids. Uniaxial geogrids are designed to provide strength in one direction, typically used for reinforcement applications. Biaxial geogrids offer strength in both directions, making them suitable for applications such as soil stabilization and slope reinforcement. Triaxial geogrids have additional strength in the third dimension, making them ideal for applications involving heavy loads or high tensile forces.

- Yes, geogrids are typically resistant to puncture due to their durable construction and materials used. They are designed to withstand various stresses and loads, including sharp objects and heavy loads without getting punctured.

- Yes, geogrids can be used in reinforced soil slopes for seismic applications. Geogrids are commonly used as reinforcement elements in soil structures to improve their stability and resistance to seismic forces. They provide additional tensile strength, prevent soil movement, and enhance the overall performance of the slope during seismic events.

- Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method?

- Have you ever studied probability statistics?

- Geogrids and geosynthetic clay liners (GCLs) are two different types of geosynthetics used in various civil engineering and environmental applications. Geogrids are typically made of high-strength polymer materials, such as polypropylene or polyester, and are designed to provide reinforcement and stabilization to soil structures. They have a grid-like structure with open apertures, allowing soil particles to interlock within the grid, improving load distribution and preventing soil erosion. Geogrids are commonly used in slope stabilization, retaining walls, and road construction. On the other hand, geosynthetic clay liners (GCLs) are composite materials consisting of a layer of bentonite clay sandwiched between two geotextile layers. Bentonite clay is highly absorbent and expands upon contact with water, creating a low permeability barrier. GCLs are primarily used as hydraulic barriers for containment applications, such as landfill liners, pond liners, and wastewater treatment facilities. They provide excellent resistance to liquid flow and act as a barrier to prevent the migration of contaminants. In summary, the main differences between geogrids and geosynthetic clay liners lie in their composition, purpose, and applications. Geogrids focus on soil reinforcement and stabilization, while GCLs are primarily used as barriers to control liquid flow and prevent the migration of contaminants.

- The effect of polymer type on geogrid behavior is significant as it determines the strength, durability, and overall performance of the geogrid. Different polymers have varying tensile strength, elongation characteristics, and resistance to environmental factors such as UV radiation and chemical exposure. Therefore, the choice of polymer type directly impacts the geogrid's ability to provide reinforcement, soil stabilization, and load distribution in geotechnical applications.

- Geogrids enhance the performance of flexible retaining structures by providing reinforcement and stability to the soil. They distribute the loads more evenly, reducing the stress on the structure and increasing its overall strength. Geogrids also prevent soil erosion and improve drainage, ensuring the long-term integrity and durability of the retaining structure.