Asphalt Geogrid

Asphalt Geogrid Related Searches

Led For Cannabis Growing Fiberglass Sheets For Roofing Geogrid For Road Construction Geogrid For Erosion Control Geogrid For Soil Stabilization Geogrid For Horse Paddocks Geogrid For Gravel Geogrid For Pavers Geogrid For Steep Slopes Geogrid For DrivewaysHot Searches

Aluminum Diamond Plate For Sale Gas Powered Core Aerator For Sale Concrete Plasticizer For Sale Concrete Slabs For Sale Revolution 4 Propeller For Sale Ex Display Log Cabins For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For Sale Buy Limestone For Carving Buy Alabaster For Carving China Cutting Aluminum Plate 1 4 Aluminum Diamond Plate Price 4x8 Aluminum Diamond Plate Price 4x8 Diamond Plate Aluminum Price Wholesale Cutting Aluminum PlateAsphalt Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Asphalt Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Asphalt Geogrid firm in China.Hot Products

FAQ

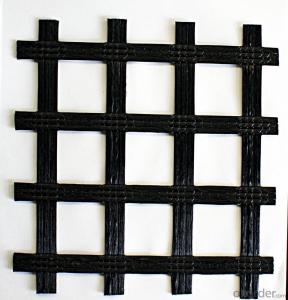

- Geogrids and geotubes are both used in geotechnical engineering, but they serve different purposes. Geogrids are typically used for soil stabilization and reinforcement, where they are placed within the soil to distribute loads and improve the overall strength of the structure. On the other hand, geotubes are large, cylindrical containers made of geotextile fabric, filled with sand or other materials, and used for shoreline protection, erosion control, and dewatering. While both geogrids and geotubes are beneficial in their respective applications, their differences lie in their form, function, and the specific challenges they address.

- Geogrids help in reducing the risk of soil compaction by providing reinforcement and stability to the soil. They distribute the load evenly and prevent excessive pressure on the soil, thereby reducing the chances of compaction. Additionally, geogrids enhance the load-bearing capacity of the soil, allowing it to withstand heavier loads without compacting.

- Geogrids are commonly used in various civil engineering applications. They are primarily used for soil stabilization, reinforcement, and erosion control in projects such as retaining walls, slopes, embankments, roadways, and pavements. Geogrids help improve the overall strength and stability of these structures by distributing loads, reducing lateral movement of soil, and preventing soil erosion.

- Quality assurance measures for geogrid installation include: 1. Proper preparation of the subgrade: Ensuring that the subgrade is well-graded, compacted, and free from any debris or vegetation is crucial before geogrid installation. This ensures a stable base for the geogrid and enhances its effectiveness. 2. Correct geogrid selection: Choosing the appropriate type and strength of geogrid based on the specific project requirements and design specifications is essential. This involves considering factors such as load capacity, soil type, and expected performance. 3. Accurate geogrid placement: Ensuring that the geogrid is correctly positioned and securely anchored is vital for its effectiveness. Careful attention should be paid to the alignment, overlap, and anchorage of the geogrid to prevent any shifting or displacement during and after installation. 4. Proper tensioning: Geogrids need to be adequately tensioned to achieve the desired tensile strength and load distribution. This requires following manufacturer guidelines and using appropriate tensioning equipment to achieve the recommended elongation or strain. 5. Regular inspection and testing: Conducting frequent inspections during geogrid installation helps identify any defects, damage, or non-compliance with specifications. Additionally, conducting pull-out tests or other relevant performance tests can verify the geogrid's adherence to the desired strength and load-bearing capacity. 6. Documentation and record-keeping: Maintaining comprehensive documentation of geogrid installation, including materials used, installation procedures, test results, and any deviations or corrective actions taken, ensures traceability and accountability. This documentation can be valuable for quality control and future reference. By implementing these quality assurance measures, geogrid installation can be carried out effectively, ensuring the desired performance and longevity of the geogrid system.

- Geogrids help in reducing the risk of landslides by providing stability and reinforcement to the soil. They are typically made of high-strength polymers and are installed horizontally or vertically within the soil mass. By interlocking with the soil particles, geogrids improve the overall strength of the soil and enhance its resistance to shear forces. This reinforcement helps to prevent soil movement and sliding, thereby reducing the likelihood of landslides.

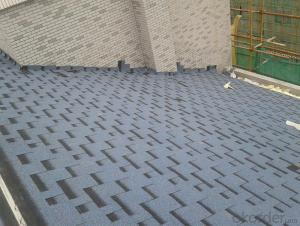

- What are the application of Geogrid in the construction of cement concrete pavement

- On the basis of the surface of a layer of geogrid poured concrete

- Bi directional plastic geogrid is suitable for engineering

- Slope protection, wall reinforcement, large airport, parking lot

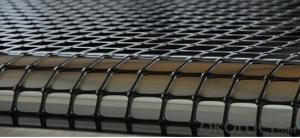

- Is it possible to add fiberglass grille between asphalt pavement and asphalt pavement

- First look at the drawing design requirements