Refractory Use Alumina Aluminum Oxide AL2O3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Use Alumina Aluminum Oxide AL2O3

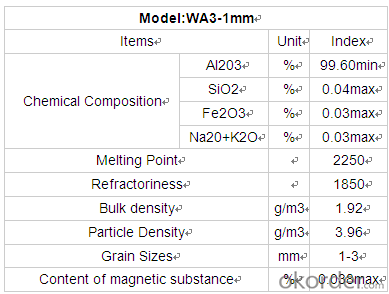

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application:

1- Used as refractory material in electronic, metallurgical,textile and oxidizing industry.

2- castable refractory product for brick,wall, plate or cover.

3- Suitable for atmospheric temperature recovering equipment.

4- A fluorine removal agent of drinking water.

5- temperature resistance above 1700 degree.

5. at high temerature, transform into alpha alumina.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q:Who knows about the grade C fireproof door materials?

- There are no differences in the interior materials of the grade A , B and C fire doors, they all use fire?rock?wool?boards. The only difference is the thickness of built-in fire rock wool boards. The rock wool boards' thickness of grade A fire doors is 52 mm, that of grade B is 46mm, and that of grade C is 40 mm.

- Q:What are the characteristics of magnesium fireproof plate

- Glass magnesium fire resistance plate is fire proof, water proof, noise insulative, heat perservative, non-toxic and tasteless, corrosion proof, easy for construction, can be sawed and nailed and have a wide range of applications as well as long service life. These advantages allow it to be widely used in construction, decoration, fire protection and be the best material to replace is to replace plywoods, MDF, particleboard, gypsum board. It is a key environmental building materials recommended by national association of construction and decoration. 1 superior fire resistance performance. 2 weather fastness, long service life. 3. light weight and anti-seismic 4 high toughness, good impact resistance and compression resistance. 5 green and environmental 6 economical 7 sound insulative and heat insulative 8 convenient for processing and easy for construction.

- Q:How to choose thermal insulation materials for flood heating?

- By controlling the foaming ratio, nucleating agent size, moudle pressure, temperature of screw, vacuum foaming technology, extruded sheet of different density can be made. The density of commonly used plastic extruded board is 25-50 kg per cubic meter. Plate density is the main factor affecting the cost of the extruded plate. The higher the plate density, the higher the cost price. Plate density is the main factor affecting the cost of the extruded plate. The lower the density of extruded board, the worse quality performance. Plate density of common plastic extruded is between 30 to 38 kilograms per cubic meter. The density of plastic extruded plate of exterior wall is between 30-35, if the density is too low, then the plate will not be strong enough, if high, flexibility of plastic extruded board will be inadequent, unable to bear the stress brought by housing settlement deformation, resulting in cracks in the wall. With the extrusion plate for floor heating should be in 36 kilograms per cubic meter. If it is too low, ground subsidence will occur due to the low strength, resulting in the ground crack. If density is too high, the thermal conductivity coefficient will increases, impacting energy saving. High density extruded plate is generally used for occasions having special requirements for compressive. Parking lot roof should use extruded plate above X350, whose density is 40 kg per cubic meter. The aircraft need to use the Ping extruded board above X500, density in 45 kilograms per cubic meters. High speed railway subgrade need to use extruded plastic board above 700KPA,

- Q:I would like to know if there is any requirement for refractories in the crucible type high-frequency smelting furnace Worry! I hope you can help me! This time!

- Stable chemical properties. The crucible material should not be hydrolyzed at low temperature. It is difficult to be decomposed and reduced at high temperature and is not susceptible to corrosion by molten slag and molten metal;

- Q:what's the fireproof levels of fireproof and thermal inuslation matertial?

- What are the fireproof levels of fireproof and thermal inuslation matertial on the market? how to divide the fireproof levels of fireproof and thermal insulation material?

- Q:How many types of special refractories are there?

- Metal ceramics, high temperature coatings, high temperature fiber and other reinforced materials

- Q:How many kinds of A-level fireproof and thermal insulation materials are there?

- Inorganic insulation materials basically can achieve the goal, such as glass wool, rock wool, and foam glass. The phenolic foam in the organic foam material is special. Phenolic foam is not only good at insulation, but also good at compounding with steel and other materials to achieve A-level performance, and the A-level insulation materials are: Rock(ore) wool, foam glass and inorganic thermal insulation mortar.

- Q:Kinds of refractory mortar

- Refractory mortar can be divided into ordinary refractory material and special refractory material. Ordinary refractory materials can be divided into acidic, neutral and alkaline refractory materials chemical properties. Special refractory material can be divided into high temperature oxide, refractory compounds and high-temperature composite materials according to their components. Furthermore, according to refractoriness, it can be divided into general refractory products (1580 ~ 1770 ℃), high grade refractory products (1770 ~ 2000 ℃) and super refractory products (2000 ℃ above). It can be divided into bulks (standard bricks, special-shaped bricks, etc.), special shapes (crucible, sagger, pipe, etc.), fibrous (aluminum silicate, zirconia filter and boron carbide , etc.) and indefinite shape (refractory clay, pouring materials and ramming mass, etc.). According to the sintering process, it is divided into sintered products, fused cast products and melting jetting products.

- Q:Can anyone tell me what material the first rate fire resistant door is?

- Material of Class A fire doors mainly are steel, wood, steel and wood, and other materials. Fire door is one of the measures of the building fire separation, usually used on the firewall, entrance and exit of staircase or tube well openings, which is required to hane the abilities of smoke insulation and fire insulation. Fire door plays an important role in prevention of the spread of smoke and fire and the reduction of fire loss. Therefore, we must have strict requirements. Fire doors are divided into class A, class B and class C, whose properties of fire-resistant thermal insulation and fire-resistant integrity should be no less than the following values: Class A should be1.50h; class B should be1.0h; Class C should be 0.5h. - stipulations in article 4.5.1.2 in "The New Standard of Fire Doors" GB12955-2008. I hope my answer can help you. Thank you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Use Alumina Aluminum Oxide AL2O3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords