Low Price Steel Billets 3sp 5sp for Sale/Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Item: steel billets

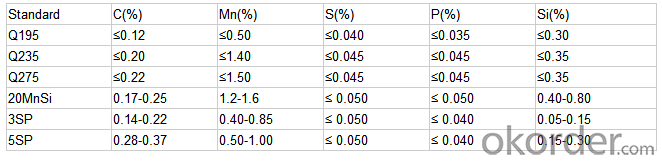

Material Grade: Q195/Q235/Q275/Q345/3SP/5SP/20MnSi

Standards: GB, ASTM, BS, EN, JIS

Technique: hot rolled

Shape: Square

Size: 120mm*120mm, 150mm*150mm

Length: 6m/12m

Bending: No more than 5mm in 1 meter, No more than 30mm in 6 meter, No more than 60mm in 12 meter

Angular Twist: No more than 1 degree per meter and not more than 6 degree over 12 meter length.

Chemical Composition:

1) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

3)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Hot Rolled Square Steel Billet/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q:What are the common types of steel products used in the wastewater treatment industry?

- The common types of steel products used in the wastewater treatment industry include stainless steel pipes, tanks, and fittings, as well as steel grating and covers for drainage systems. These materials are chosen for their corrosion resistance, durability, and ability to withstand harsh chemical environments commonly found in wastewater treatment facilities.

- Q:What are the advantages of using steel in the manufacturing of tanks and vessels?

- There are several advantages of using steel in the manufacturing of tanks and vessels. Firstly, steel is known for its exceptional strength and durability, making it highly resistant to corrosion and damage from external factors. This ensures the longevity of tanks and vessels, reducing the need for frequent repairs or replacements. Additionally, steel's high tensile strength allows for the construction of tanks and vessels with thinner walls, maximizing storage capacity while maintaining structural integrity. Moreover, steel is a versatile material that can be easily formed into various shapes and sizes, allowing for customization and efficient use of space. Lastly, steel is a cost-effective option due to its availability, recyclability, and low maintenance requirements, making it a preferred choice for the manufacturing of tanks and vessels.

- Q:How do steel products withstand extreme temperatures and weather conditions?

- Steel products are able to withstand extreme temperatures and weather conditions due to their inherent strength and durability. Steel is a highly resilient material that can withstand high temperatures without melting or deforming. Additionally, steel is corrosion-resistant, making it resistant to the damaging effects of weather conditions such as rain, snow, and humidity. Furthermore, steel can be coated with protective finishes to enhance its resistance to extreme temperatures and weather, ensuring its longevity and reliability in various environments.

- Q:What are the different types of steel products used in the manufacturing of pet accessories?

- There are several types of steel products used in the manufacturing of pet accessories, including stainless steel bowls, steel leashes and collars, steel grooming tools, and steel cages or crates.

- Q:How is steel used in the manufacturing of elevators and escalators?

- Steel is used extensively in the manufacturing of elevators and escalators due to its strength, durability, and load-bearing capabilities. It is utilized in various components such as the elevator car, support structures, guide rails, and escalator steps. The steel framework provides the necessary stability, while its corrosion resistance ensures a long lifespan for these transportation systems.

- Q:How is steel used in the construction of railway bridges?

- Steel is commonly used in the construction of railway bridges due to its strength, durability, and ability to withstand heavy loads. It is used to create the main structural components of the bridge, such as beams, girders, and columns, providing the necessary support and stability for the railway tracks. Steel is also used for various other elements, including the bridge deck, railings, and connections, ensuring the overall integrity and safety of the bridge.

- Q:How is steel sheet metal bent for HVAC ductwork?

- Steel sheet metal is bent for HVAC ductwork using a machine called a brake press. The metal sheet is inserted into the brake press, and a die and punch system is used to apply pressure and create the desired bend. This process allows for precise and consistent bending of the sheet metal to form the necessary shapes and angles required for HVAC ductwork.

- Q:How is steel used in the construction of theme parks and recreational facilities?

- Steel is used in the construction of theme parks and recreational facilities for various purposes, such as the creation of structural supports, roller coasters, rides, and other attractions. It provides strength and durability, allowing for the construction of large and intricate structures, ensuring the safety and enjoyment of visitors. Additionally, steel is also used in the fabrication of fencing, gates, and other components, contributing to the overall aesthetics and functionality of these facilities.

- Q:How do steel products contribute to the construction of zoos and wildlife sanctuaries?

- Steel products play a vital role in the construction of zoos and wildlife sanctuaries by providing structural support and durability to various facilities and enclosures. Steel is used to construct enclosures, fences, gates, and animal habitats, ensuring the safety and security of the animals and visitors. Additionally, steel is used in the construction of walkways, viewing platforms, and bridges, allowing visitors to have a closer and safer interaction with the animals. Its strength and versatility make steel an essential material in creating a sustainable and long-lasting environment for the animals, while also enhancing the overall aesthetics of these facilities.

- Q:How is steel used in the production of marine equipment and vessels?

- Steel is extensively used in the production of marine equipment and vessels due to its high strength, durability, and resistance to corrosion. It is used to construct the hull, decks, and superstructures of ships, providing structural integrity and ensuring the vessel's stability. Additionally, steel is used to fabricate various components such as propeller shafts, rudders, and cargo holds, contributing to the overall functionality and efficiency of marine equipment and vessels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Price Steel Billets 3sp 5sp for Sale/Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords